Method for preparing theaflavin and thearubigin from fresh green tea

A technology for fresh green tea and thearubigin, which is applied in the fields of food preparation, chemical instruments and methods, tea extraction, etc., can solve the problems of unrecoverable chemical reagents, and achieve the effects of low cost, environmental protection and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

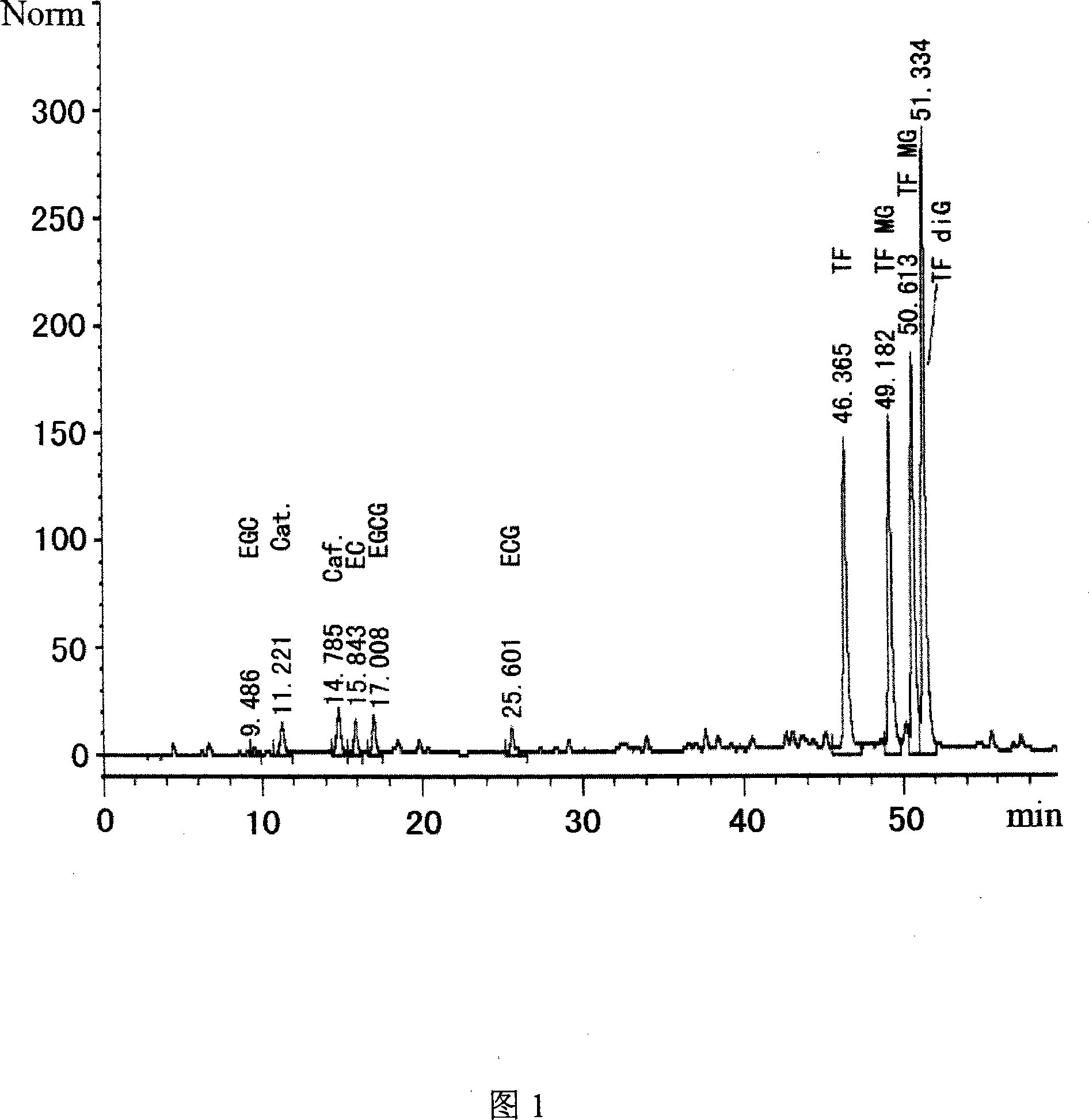

Image

Examples

Embodiment 1

[0028] 1. Pretreatment of raw materials:

[0029] 1) Remove impurities from the raw materials, wash them and place them in a cool and dry place for 8 hours;

[0030] 2) Grind the cooled raw materials.

[0031] 2. Preparation of theaflavins and thearubigins

[0032] 1) Put the pulverized raw materials into a fermenter, add 3 times the volume of pure water and loquat juice equivalent to 0.5 times the quality of the raw materials, feed air under the conditions of temperature 35°C and pH=4.5 and stir at a high speed, Natural fermentation for 20 minutes;

[0033] 2) After the fermentation is over, stop adding air, heat up the temperature rapidly to 100°C, keep it for 15 minutes, then add 1 times the volume of 95% ethanol, stir for 20 minutes, centrifuge to obtain the supernatant and precipitate, and use 2 times 50% ethanol for the precipitate Extract once with % ethanol for 30 minutes, centrifuge to obtain the supernatant and precipitate; combine the supernatant obtained after t...

Embodiment 2

[0040] 1. Pretreatment of raw materials:

[0041] 1) Remove impurities from the raw materials, wash them and place them in a cool and dry place for 10 hours;

[0042] 2) Grind the cooled raw materials.

[0043] 2. Preparation of theaflavins and thearubigins

[0044] 1) Put the pulverized raw materials into a fermenter, add 5 times the volume of pure water and apple juice equivalent to 1 times the weight of the raw materials, feed air at a temperature of 40°C, and stir at a high speed under the conditions of pH=5, Natural fermentation for 30 minutes;

[0045] 2) After the fermentation is over, stop adding air, heat up the temperature rapidly to 100°C, keep it for 20 minutes, then add 2 times the volume of 95% ethanol, stir for 30 minutes, centrifuge to get the supernatant and precipitate, and use 2 times the volume of 50% ethanol for the precipitate Extract once with % ethanol for 30 minutes, centrifuge to obtain the supernatant and precipitate; combine the supernatant obtai...

Embodiment 3

[0052] 1. Pretreatment of raw materials:

[0053] 1) Remove impurities from the raw materials, wash them and place them in a cool and dry place for 12 hours;

[0054]2) Grind the cooled raw materials.

[0055] 2. Preparation of theaflavins and thearubigins

[0056] 1) Put the pulverized raw materials into a fermenter, add 8 times the volume of pure water and eggplant juice equivalent to 3 times the quality of the raw materials, and pass air under the conditions of temperature 45°C and pH=5.5 and stir at a high speed, Natural fermentation for 40 minutes;

[0057] 2) After the fermentation is over, stop adding air, heat up the temperature rapidly to 100°C, keep it for 30 minutes, then add 3 times the volume of 95% ethanol, stir for 40 minutes, centrifuge to get the supernatant and precipitate, and use 3 times the volume of 50% ethanol for the precipitate Extract once with % ethanol for 30 minutes, centrifuge to obtain the supernatant and precipitate; combine the supernatant o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com