Laboratory artificial cultivating method for intertidal zone marine sponge

A breeding method and laboratory technology, applied in the field of artificial cultivation of sponges in the intertidal zone, can solve the problems of low success rate of field cultivation, death of sponges, complicated steps, etc., and achieve simple control of dissolved oxygen concentration, wide application prospects and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 5L static water system culture.

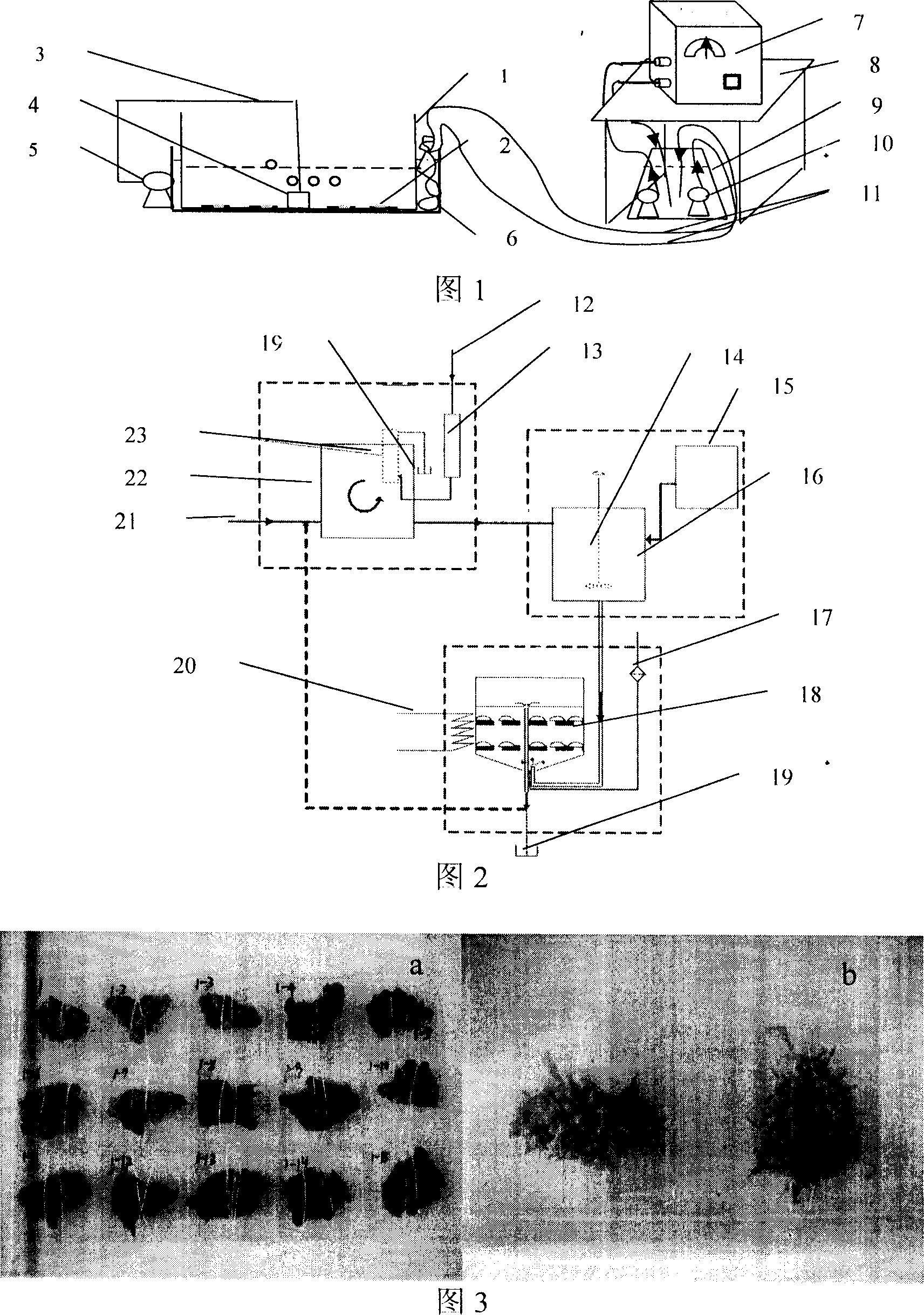

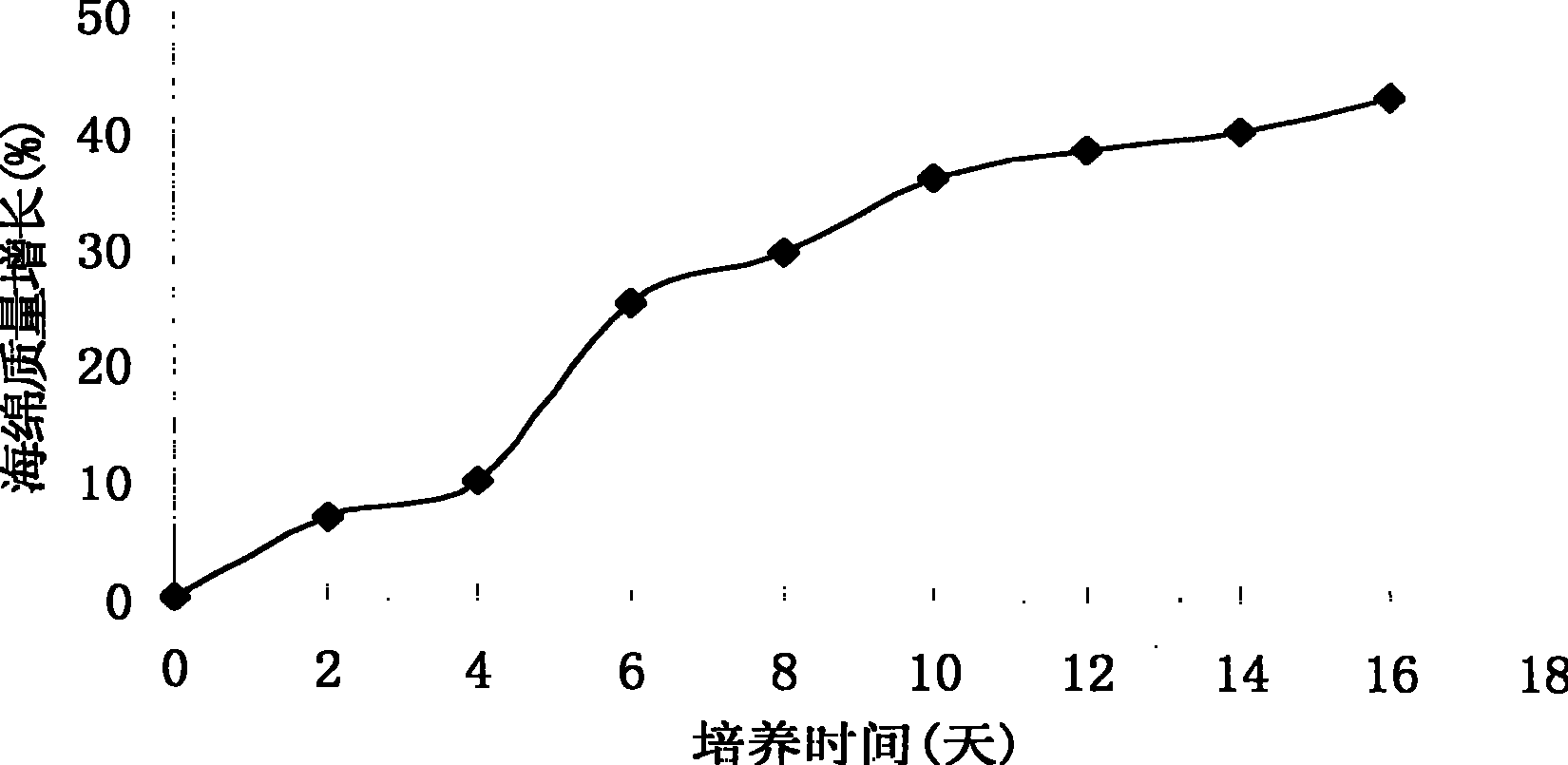

[0035] Hymeniacidon perleve was collected in the intertidal zone of Lingshuiqiao, Dalian, China in July 2005. There are few impurities and dirt on the surface of the sponge. The area selected for collection is about 2×2cm 2 After being brought back to the laboratory, it was placed in a 12L glass tank filled with seawater for temporary raising for 2 days, and the temporary raising temperature was controlled at about 20±1°C. The culture system is shown in Figure 1. At the beginning of the culture, fix the sponges on a 4×4cm frosted glass carrier with threads, put 15 pieces in total into a 5L glass tank filled with seawater, then put the glass tank arm in a water area with a temperature of about 20±2°C, and air pump Air is introduced into the gas distributor, dissolved oxygen meter is used to measure the dissolved oxygen in the water, and the air flow rate is adjusted so that the dissolved oxygen concentration in the water is within the r...

Embodiment 2

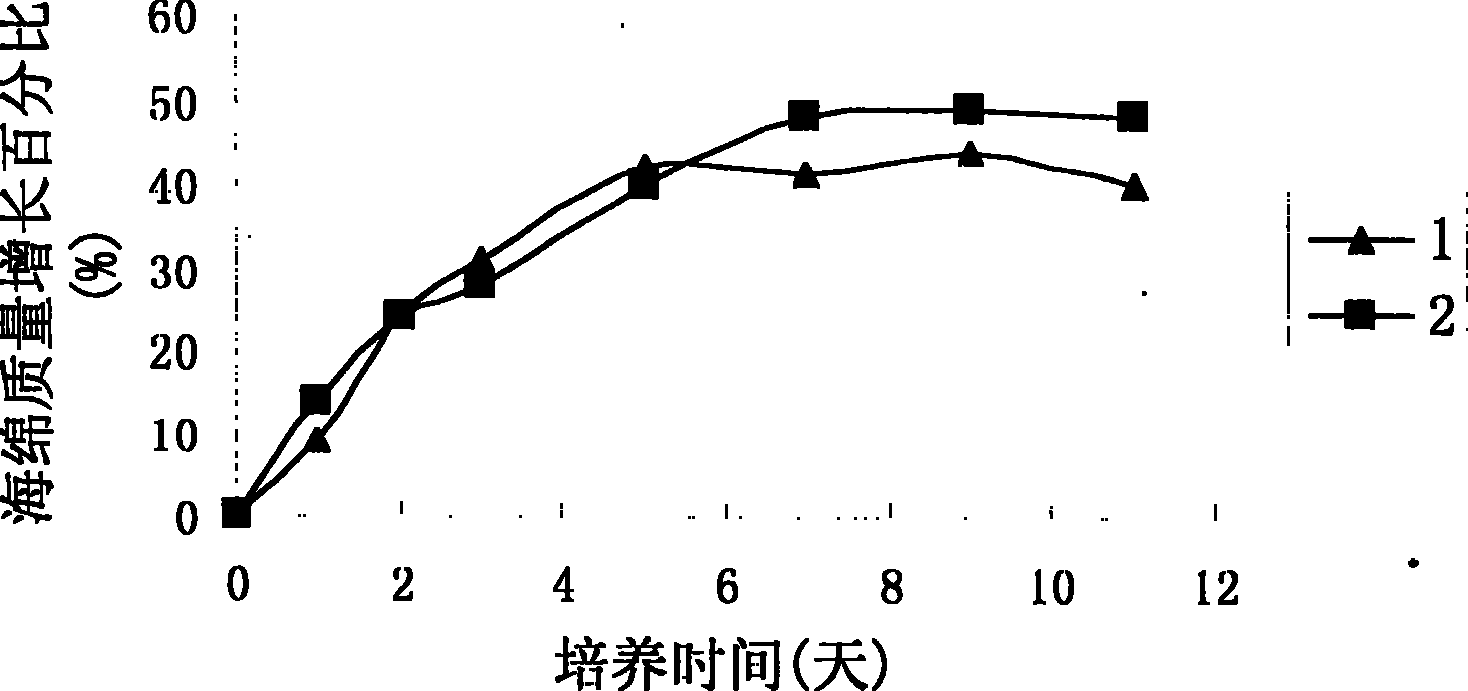

[0043] 5L fed-batch system culture. The luxuriant membrane sponge (Hymeniacidon perleve) was collected in the intertidal zone of Lingshuiqiao, Dalian, China in July 2005. After being brought back to the laboratory, it was kept in a 12L glass tank filled with seawater for 2 days, and the temperature was controlled at 18-20°C. The culture system is shown in Figure 2. At the beginning of the cultivation, the sponges were fixed on a circular frosted glass carrier with a diameter of about 5cm, a total of 15 pieces were placed in a 5L liquid liter incubator filled with seawater, the water flow rate was 20L / day, and the outside of the incubator was wrapped with a cooling tube for control The temperature of the culture water body is 20±1°C, the air pump and the gas diffuser provide the oxygen required by the sponge, the whole system is placed indoors in a place where there is no sunlight, and the food is fed with Nitzschia crescentus and Chrysophyllum equilateralis, each at a concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com