Low-cost and high-performance organic field effect transistor and its making method

An organic field and transistor technology, applied in the field of organic field effect transistors, can solve the problems of high cost and achieve the effect of low cost, simple process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of described organic field effect transistor comprises the following steps:

[0038] The first step, the deposition preparation of the source and drain electrodes

[0039] The substrate deposited with the gate electrode and insulating layer was ultrasonically cleaned with deionized water, ethanol, and acetone, and then oven-dried, then modified with octadecylchlorosilane (OTS), and then ultrasonically cleaned with n-heptane, ethanol, and acetone. Cleaned and then evaporated to deposit at least one layer of metal.

[0040] The second step, the modification of the source and drain electrodes

[0041]Drop the acetonitrile solution (5mM) of 7,7,8,8-tetracyanoquinodimethane (TCNQ) on the substrate on which the electrode is deposited, then quickly dry it, and then rinse with acetonitrile to obtain a modified organic charge Transfer the source-drain electrodes of the complex salt layer.

[0042] The third step, deposition of organic semiconductor mate...

Embodiment 1

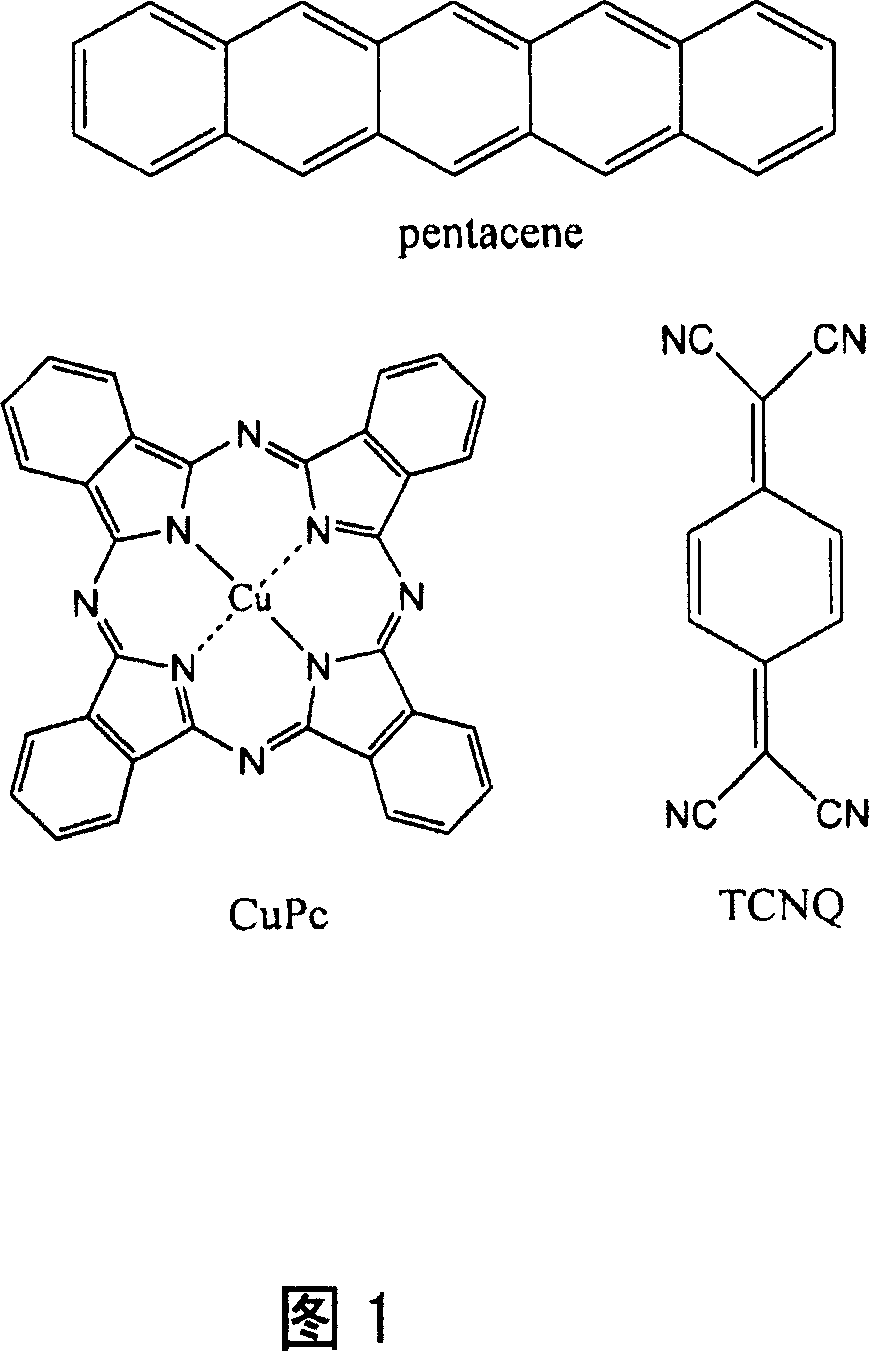

[0048] Figure 1 shows the molecular formulas of the organic materials used to prepare the present invention, which are pentacene (pentacene), copper phthalocyanine (CuPc) and 7,7,8,8-tetracyanoquinodimethane (TCNQ).

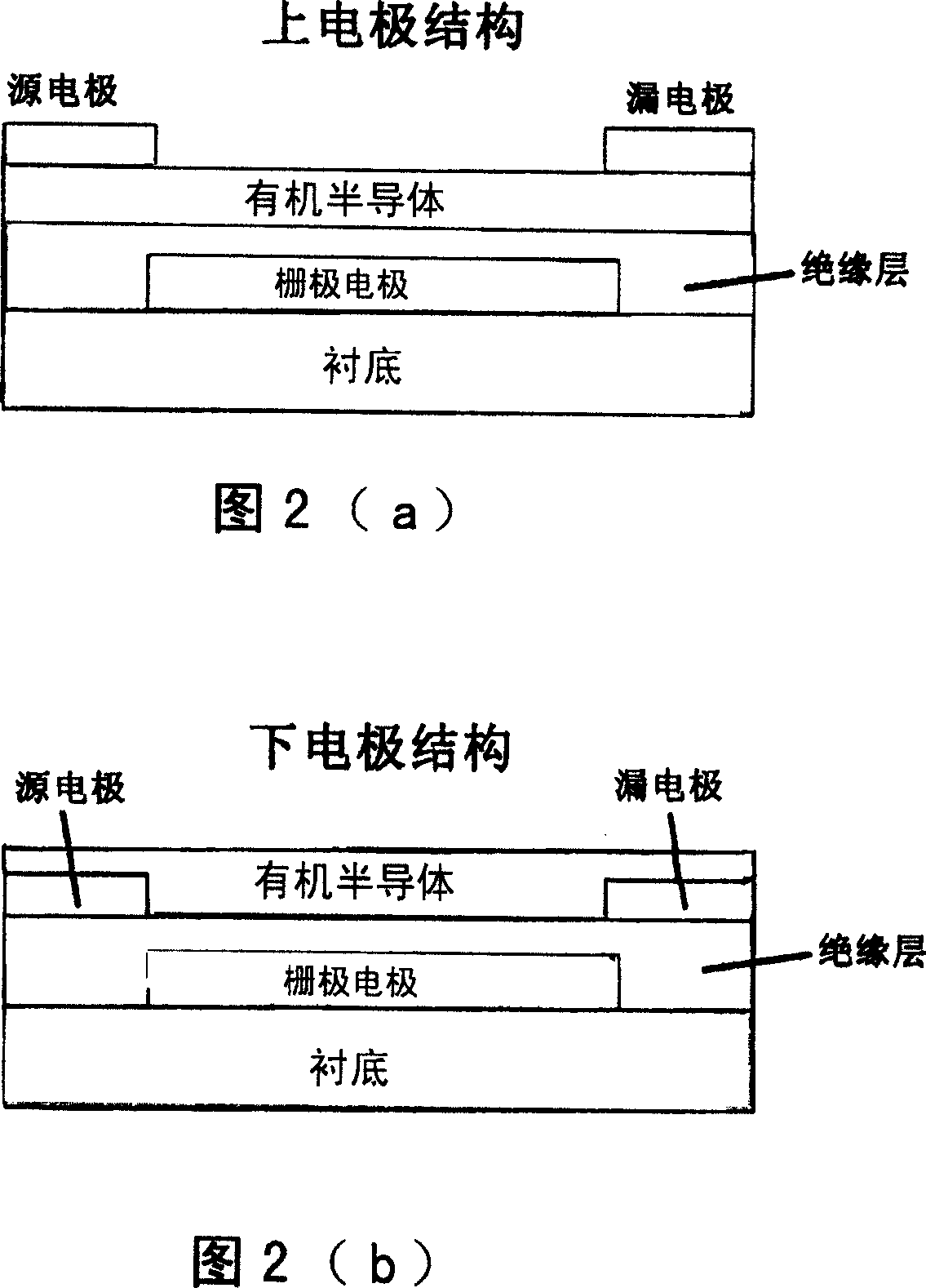

[0049] Fig. 2 schematic diagram of upper electrode structure and lower electrode structure of organic field effect transistor;

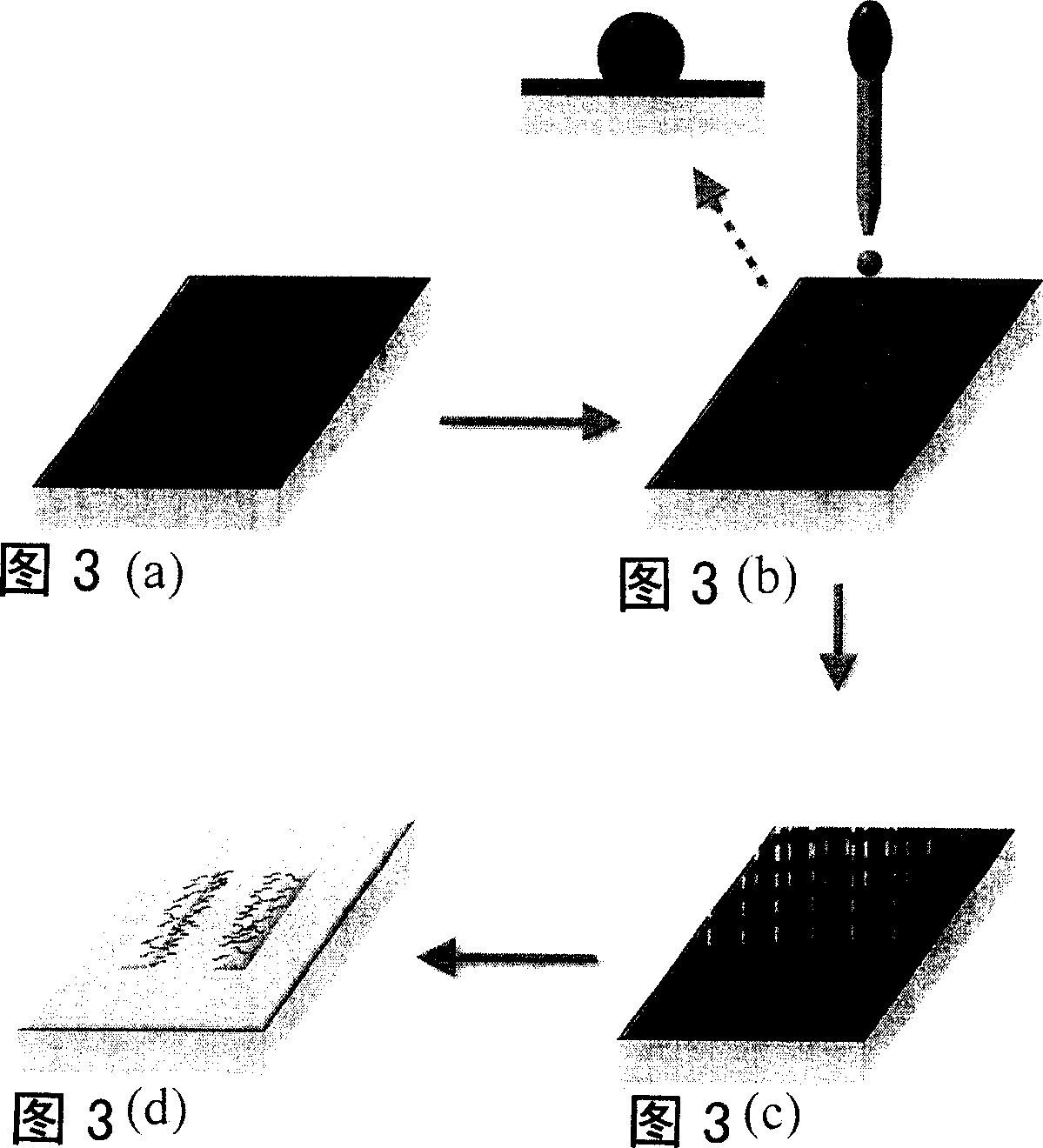

[0050] What Fig. 3 shows is the preparation flow chart of bottom electrode structure organic field effect transistor of the present invention; Wherein, Fig. 3 (a) is to depositing source-drain electrode on the substrate of silicon dioxide modified through octadecyl chlorosilane , Fig. 3(b) is to drop the acetonitrile solution of TCNQ on the substrate of prepared source-drain electrode, Fig. 3(c) is to deposit organic semiconductor on the substrate of modified electrode, Fig. 3(d) is prepared Schematic diagram of an organic field effect device.

[0051] Figure 4 is a scanning electron microscope image of the prepared device, wherein Fig...

Embodiment 2

[0065] According to the preparation of Example 1, the only difference is that Cu-TCNQ is used as the source-drain electrode, and the field-effect mobility based on pentacene is 0.056cm 2 V -1 the s -1 , an on-off ratio of 10 6 .

[0066] Referring to Fig. 6, it is the output curve and transfer curve diagram of the organic field effect transistor with Cu-TCNQ as the source and drain electrodes, and pentacene as the organic semiconductor, wherein, the output curve of Fig. 6 (a), Fig. 6 (b) It is the transfer curve when the source-drain voltage is -60V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com