Ecological protection method for sand-filling road foundation hollow block

An ecological protection and hollow block technology, applied in roads, excavation, roads, etc., can solve the problems of difficult grass planting, greening, poor durability, expensive repair of rigid lining, etc., achieve high promotion and application value, improve erosion resistance, visual beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Follow these steps:

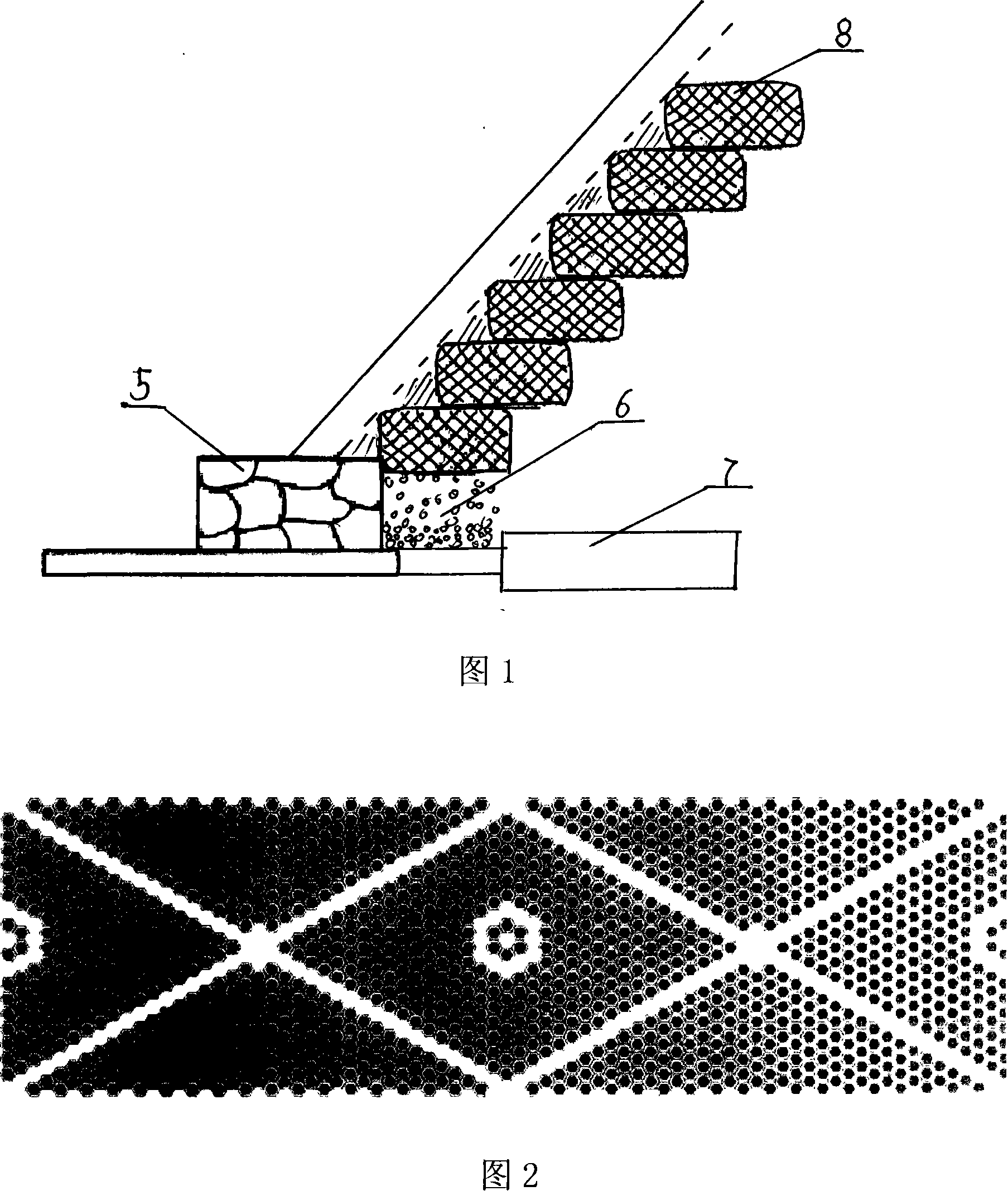

[0032] 1.1 Drainage treatment at the foot of the slope: use dry rubble 5 to protect the foot, wrap the inner side with permeable geotextile, and set a pebble filter layer 6, set a 30cm×65cm horizontal pebble blind ditch 7 every 10m along the route direction, Drain the subgrade water into the ditch to prevent the loss of sand particles;

[0033] 1.2 When the roadbed is filled with sand to the design elevation of the roadbed, the slope line of the roadbed is set back 30cm to hang the line, and 8 woven bags of sand are piled up layer by layer according to the slope height of 1:1.75. On the plane, there is a single horizontal row of woven bags, and on the facade, a layer of woven bags is a step with a width of 20cm. When yarding the slope, it must be strictly in accordance with the slope line of 1:1.75, and each floor must be filled with water.

[0034] 1.3 Backfill soil 30cm thick on the stepped woven bag slope, and manually compact it layer by laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com