Minitype compressor heat insulation type stator wheel disk

A technology for compressors and stators, applied in the field of heat-insulated stator wheels for micro-compressors, which can solve problems such as reduced efficiency, affecting cycle conditions, and reduced efficiency, achieving the effect of reducing heat transfer and improving overall machine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

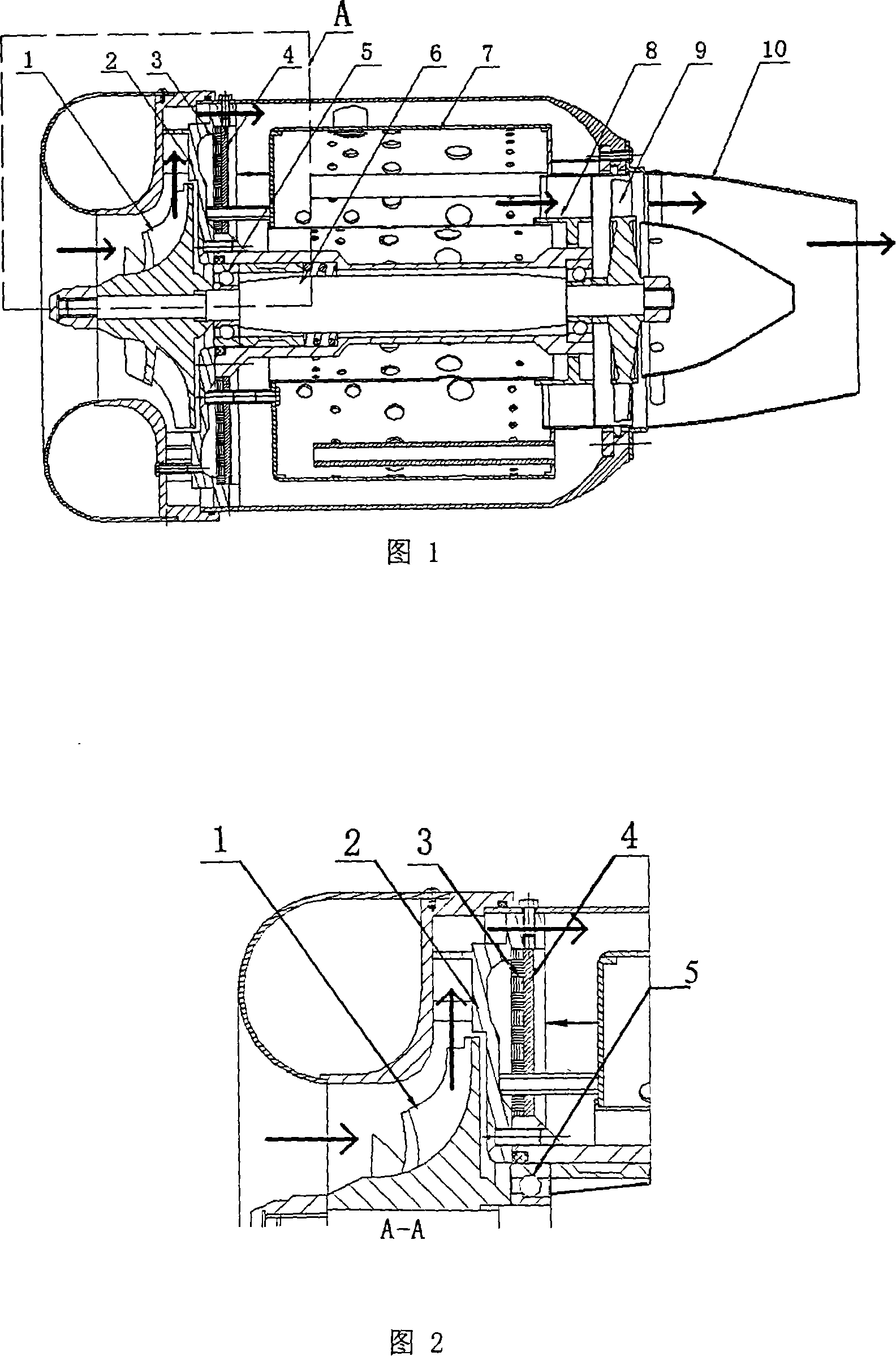

[0012] Referring to the accompanying drawings, its structure is on the back of the stator wheel of the compressor, and adopts a double-layer heat insulation layer structure.

[0013] The double-layer heat insulation layer structure: the inner layer is the main heat insulation layer, and ceramic fiber heat insulation material is used, which is pasted on the back of the stator wheel of the compressor to prevent the transfer of external heat to the stator wheel of the compressor; the outer layer is The metal film that can reflect the electromagnetic waves of heat radiation is pasted on the main heat insulation layer to reduce the heat transferred from the front face of the combustion chamber to the main heat insulation layer through heat radiation.

[0014] The main heat insulation layer is a ceramic fiber product heat insulation material made of alumina fiber, with a thickness of 1mm. Temperature ≤ 165°C.

[0015] A layer of metal film is added on the surface of the main heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com