Spontaneous heating thermal bag and method of manufacturing the same

A self-heating, warm bag technology, applied in the field of warm bags, can solve the problems of airtightness, etc., and achieve the effects of long heating time, stable and peaceful temperature, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

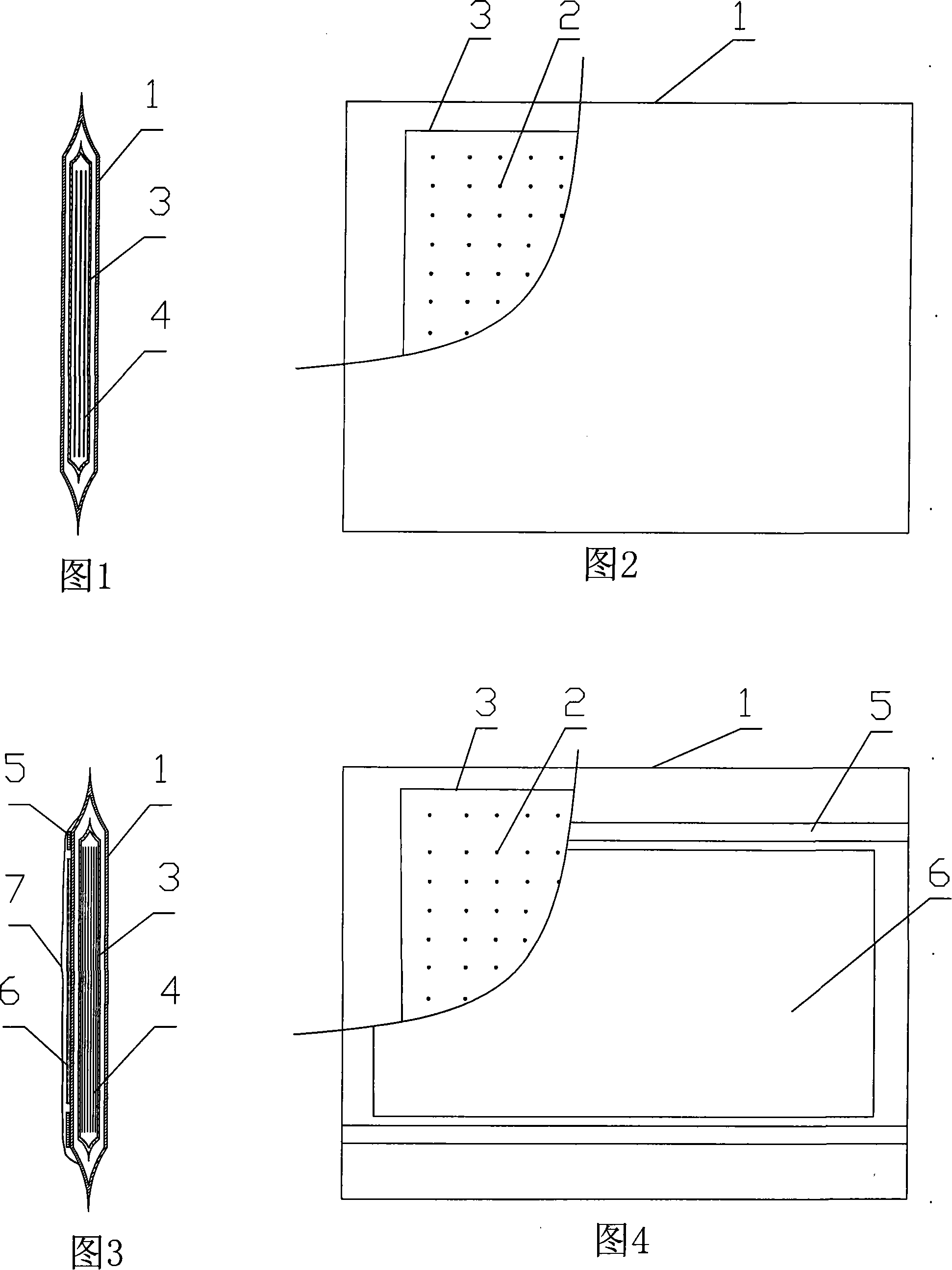

[0020] Example 1, as shown in Figures 1 and 2, a self-heating warm bag includes an outer bag 1 and an inner bag 3, the inner bag 3 is sealed inside the outer bag 1, the outer bag 1 is made of PE material, and the inner bag 3 is made of It is made of cast film with air-permeable micropores 2 on the surface, and three layers of sheet-shaped self-heating agent 4 are packaged in the inner bag 3 through heat-sealing and sealing. The sheet-shaped self-heating agent 4 is made of the following raw materials: 75g of iron powder, activated carbon 15g, salt 4g, cotton fiber 15g, gelatin 5g, water 20g.

Embodiment 2

[0021] Embodiment 2, as shown in Figures 3 and 4, a self-heating warm bag, including an outer bag 1 and an inner bag 3, the outer bag 1 is made of PP material, and the inner bag 3 is made of a composite material with air-permeable micropores 2 on the surface. The inner bag 3 is sealed inside the outer bag 1, and the inner bag 3 is sealed with six layers of sheet-shaped self-heating agent 4 through heat-sealing. The inner bag 3 has a drug layer 6 attached to the outer surface, and the drug layer 6 is for external use. Plaster, medicament layer 6 is provided with viscose layer 5 attached to inner bag 3 sides around, and plaster 6, viscose layer 5 are provided with protective film 7 outside, and protective film 7 is pulled off during use, and plaster 6 is aimed at body For the treatment part, the adhesive layer 5 can be stuck on the skin, and the curative effect of the medicine can be improved by heating with a warm bag. The sheet-shaped self-heating agent 4 is made of the follow...

Embodiment 3

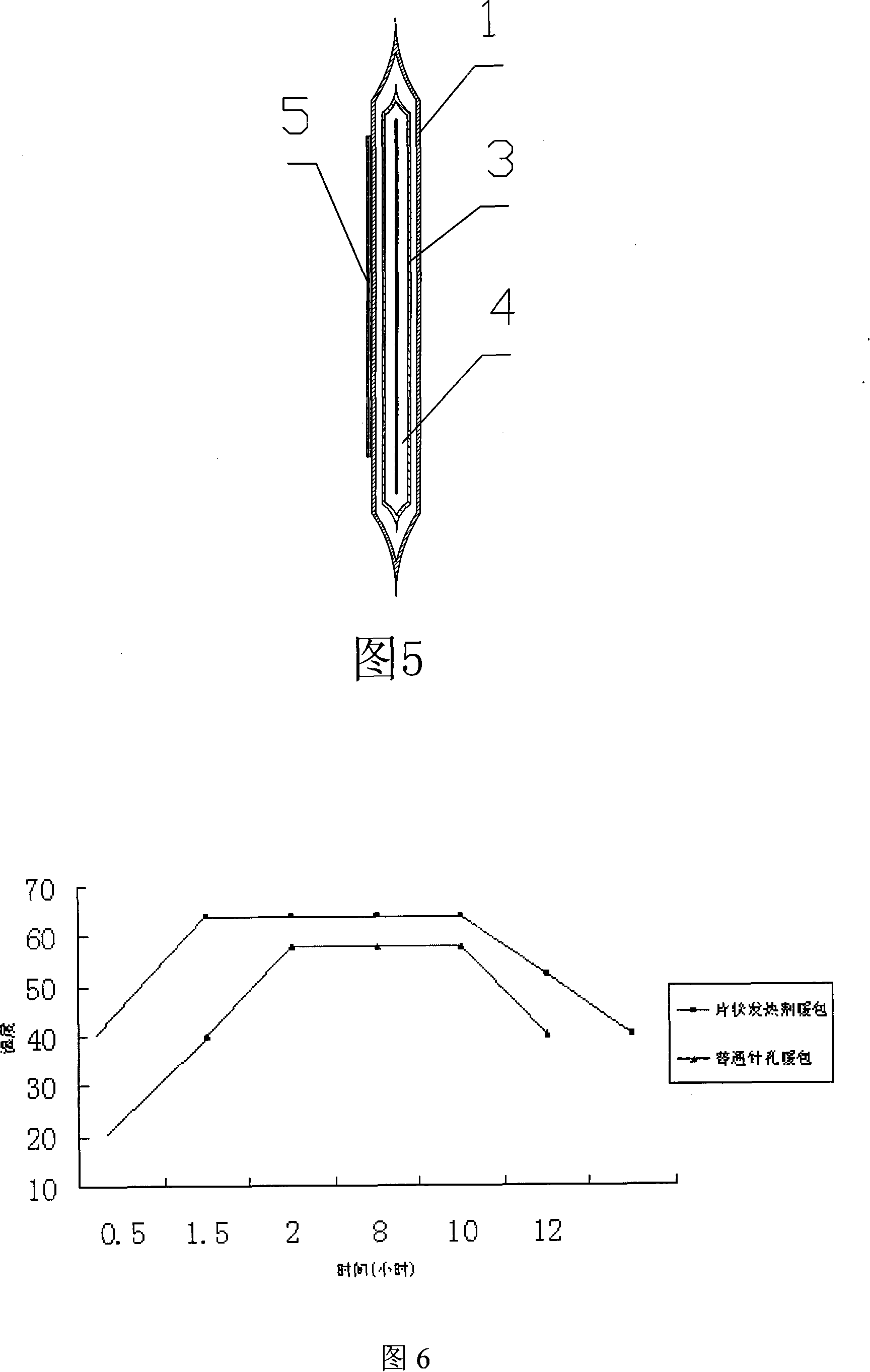

[0022] Example 3, as shown in Figure 5, a self-heating warm bag, including an outer bag 1 and an inner bag 3, the outer bag 1 is made of aluminum-plastic composite film, the inner bag 3 is sealed inside the outer bag 1, and the inner bag 3 is used Made of non-woven fabric with micropores 2, a self-adhesive layer 5 is attached and fixed on one side, and a layer of sheet-shaped self-heating agent 4 is packaged in the inner bag 3, wherein the sheet-shaped self-heating agent 4 is made of the following raw materials Ingredients: Iron powder 60g, activated carbon 5g, salt 5g, hemp fiber 20g, gelatin 3g, water 25g. According to the needs of actual calorific value and the size of the warm bag, 4-6 layers or even more layers of self-heating agent 4 in sheet form can be placed, and the self-adhesive layer 5 is uncovered and pasted on the corresponding parts of the body during use.

[0023] The preparation method of the self-heating warm bag in the above embodiment: the raw materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com