Laser beam injecting optical device for optical fiber

An optical device and laser technology, applied in optics, optical components, fluorescence/phosphorescence, etc., can solve the problem of not being able to transmit laser light, and achieve the effect of suppressing air breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

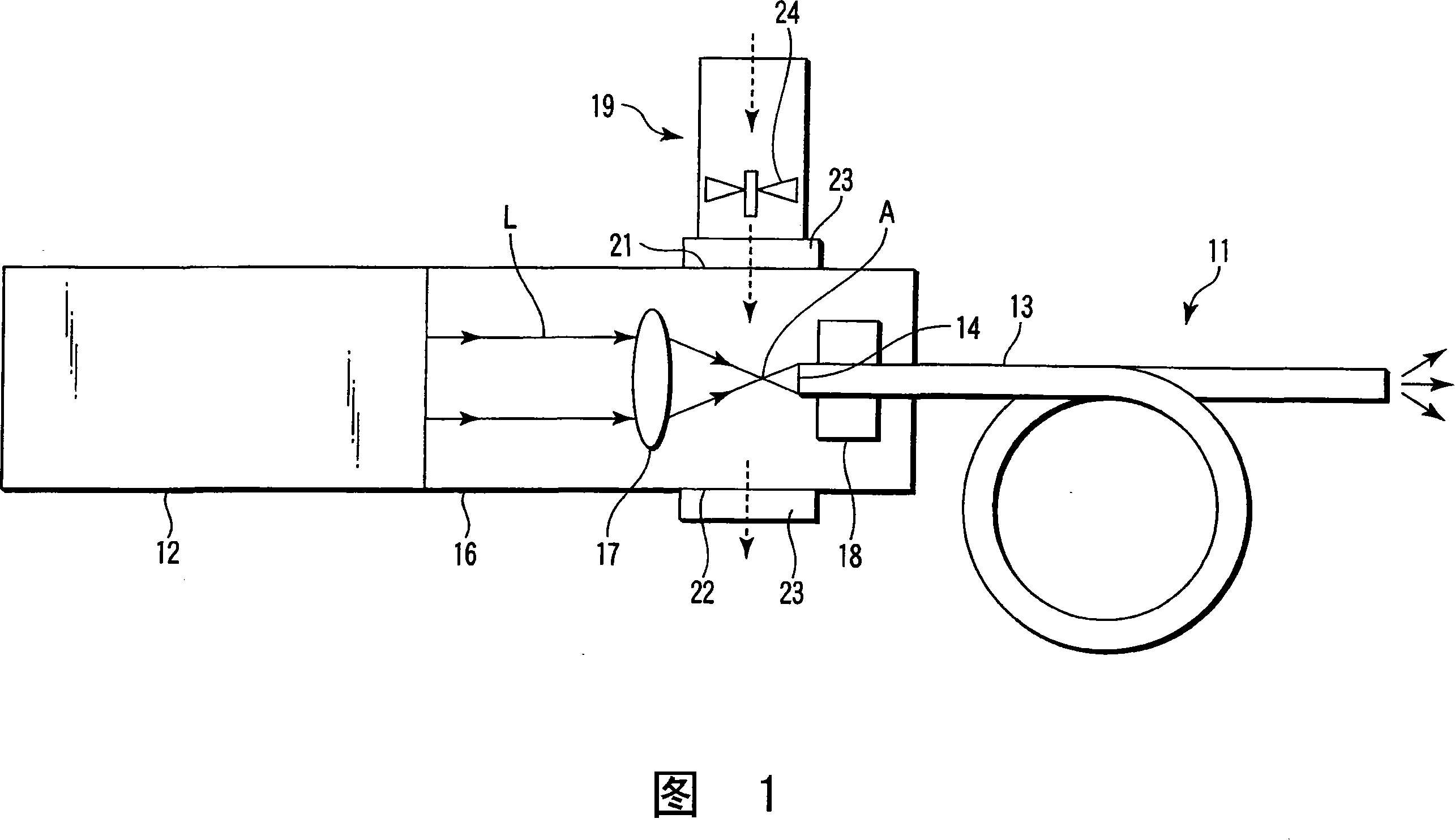

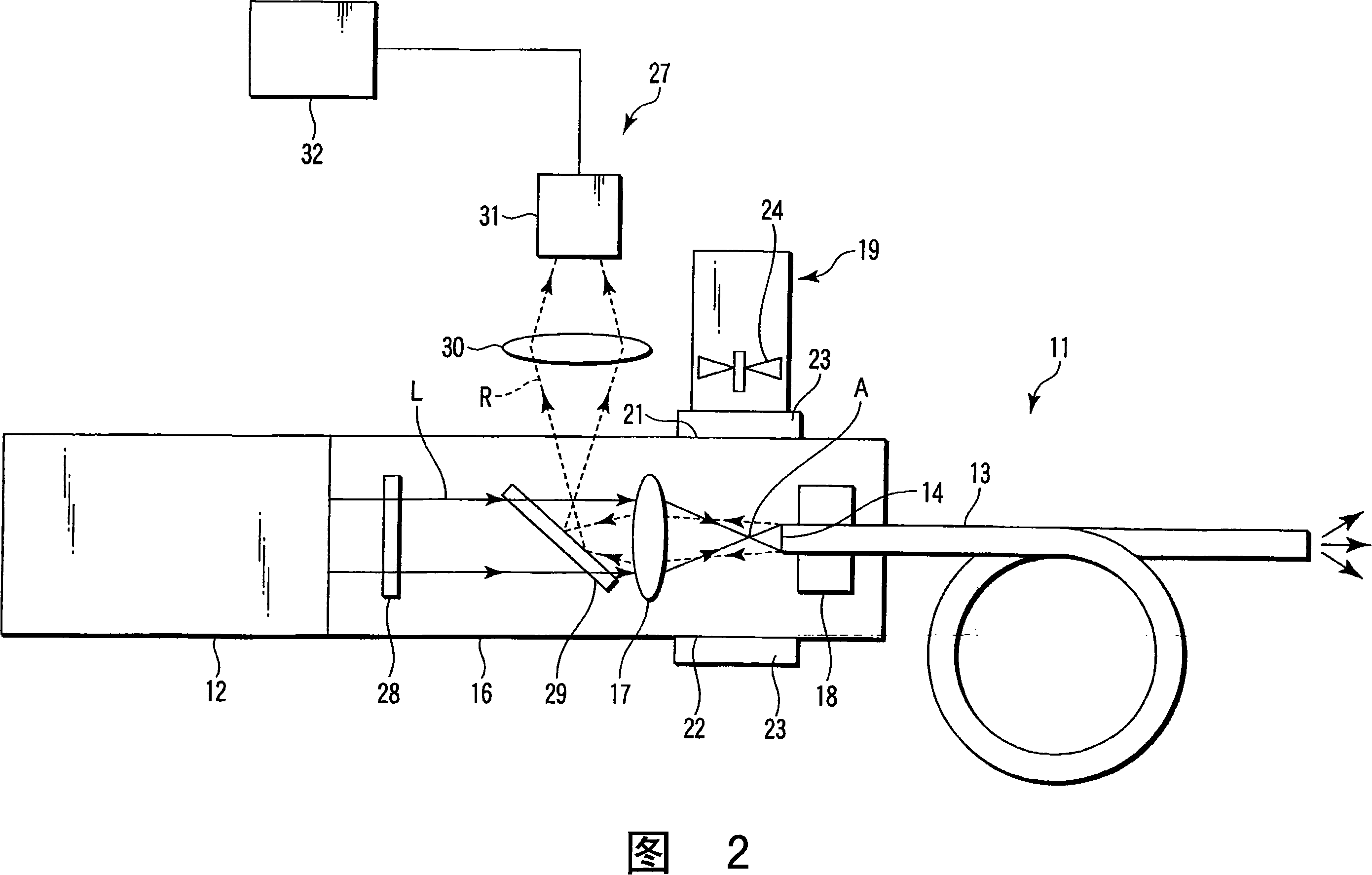

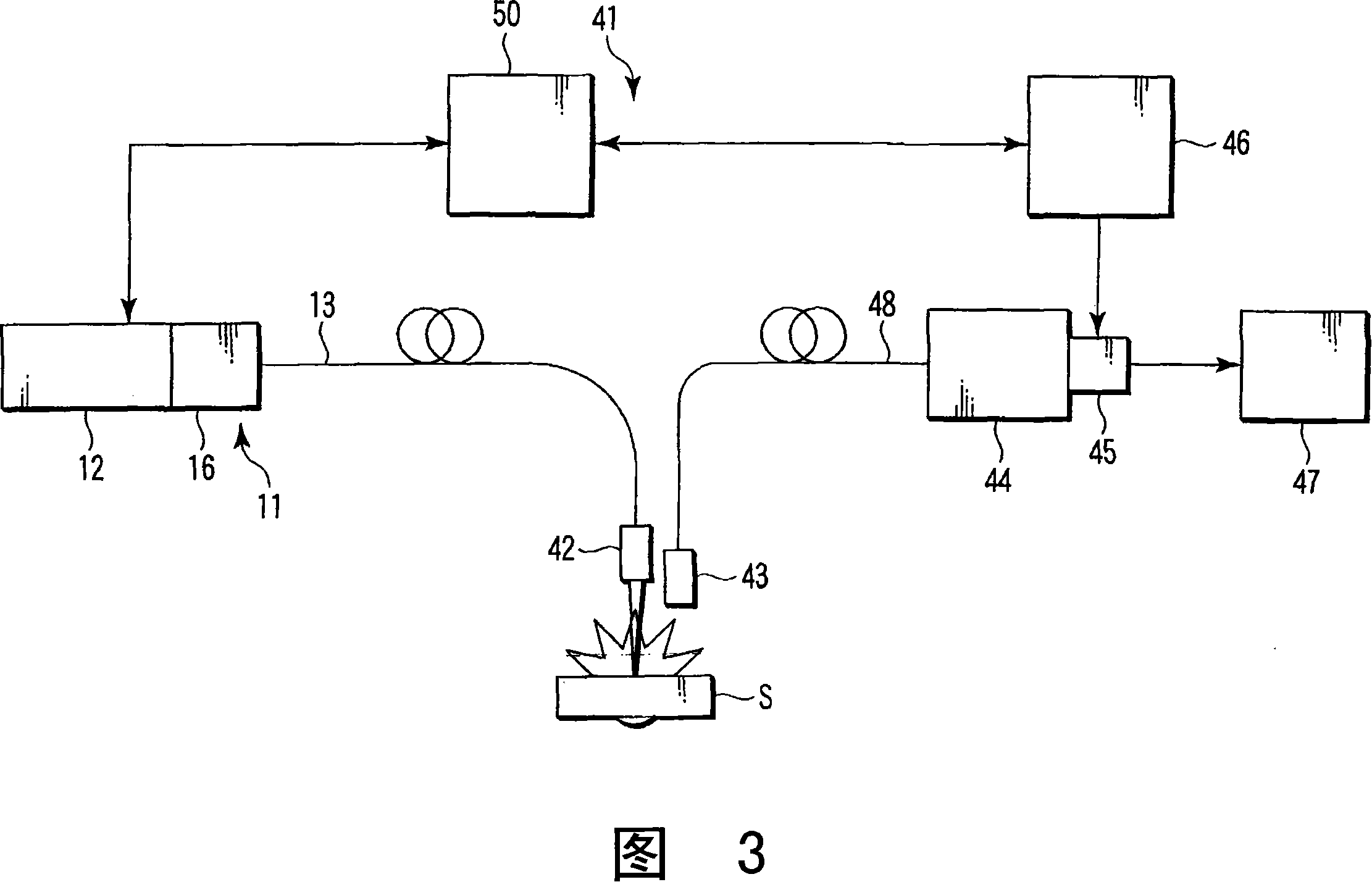

[0018] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0019] As shown in FIG. 1 , the laser incident optical device 11 for an optical fiber uses the pulsed laser light L generated by the laser oscillator 12 , which is a solid-state laser oscillator with a peak power of about 1 MW to 25 MW, so that the optical fiber 13 is not damaged. Furthermore, it is possible to transmit the stable laser light generated by the optical fiber 13 and enter the incident end face 14 of the optical fiber 13 having a predetermined core diameter and cladding thickness. In addition, if the peak power of the laser light L is greater than 25MW, the optical fiber 13 with a core diameter of about φ1mm may be damaged, so it is preferably about 25MW or less.

[0020] This optical fiber laser incident optical device 11 has a shielded container 16. At one end of the shielded container 16, a laser oscillator 12 outputting laser light L is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com