Macrotype double ram stroke diesel engine with hydraulic actuating exhaust valve

A diesel engine and engine technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve the problem that electric actuators cannot be used to operate exhaust valves, and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

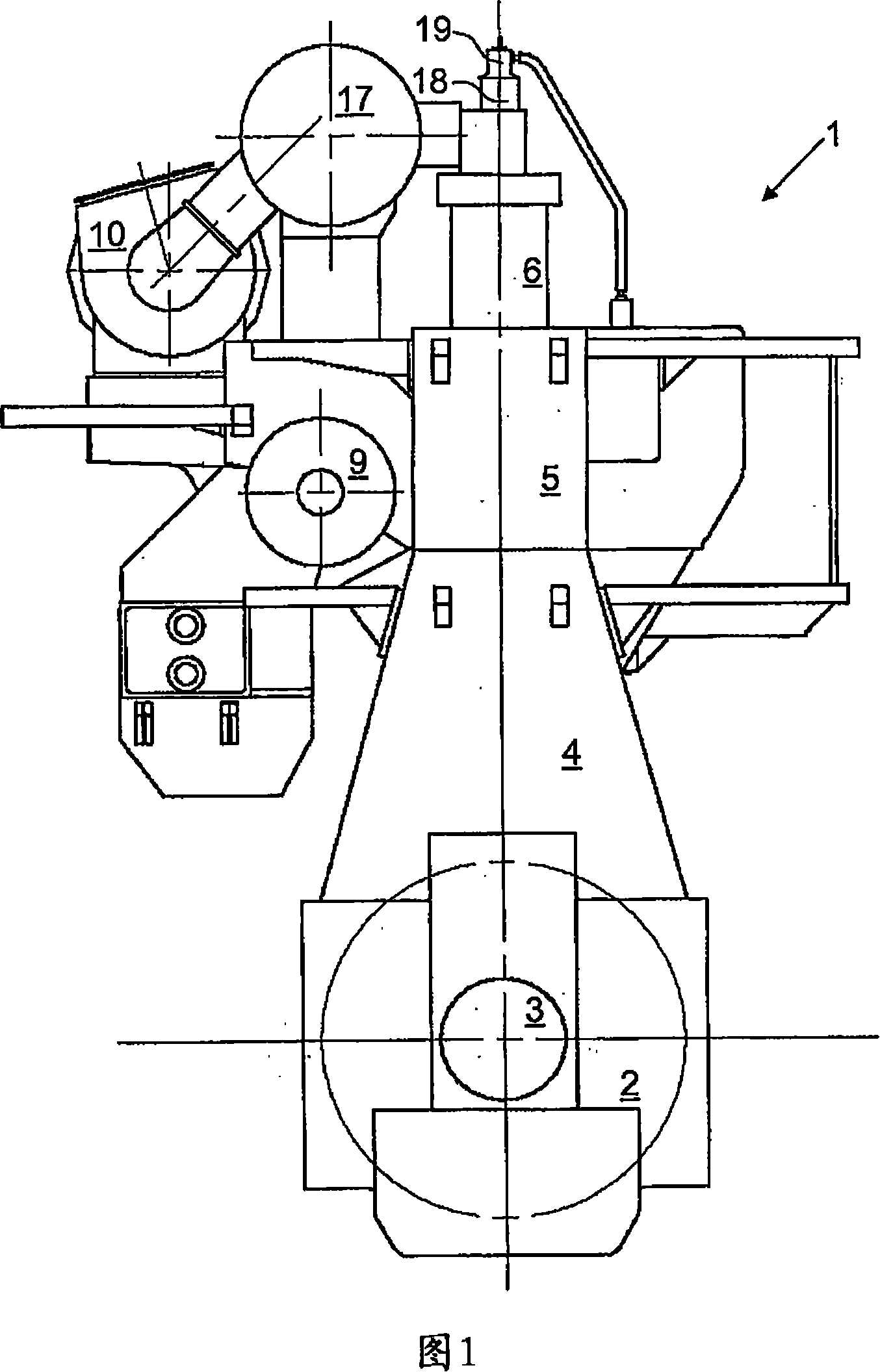

[0070] Figure 1 shows an engine 1 according to the invention. The engine is a low speed two stroke crosshead diesel engine which may be a propulsion engine in a ship or a prime mover in a power plant. These engines typically have 6 to 16 in-line cylinders. The engine is built on a foundation 2 with main bearings for the crankshaft 3 . The base is divided into sections of suitable size according to the available manufacturing equipment. A crankcase bracket 4 of welded design type A is installed on the base. The cylinder bracket 5 is mounted on top of the crankcase bracket 5 . Tension screws (not shown) connect the base to the cylinder bracket and hold the structure together. The cylinder 6 is carried by the cylinder bracket 5 .

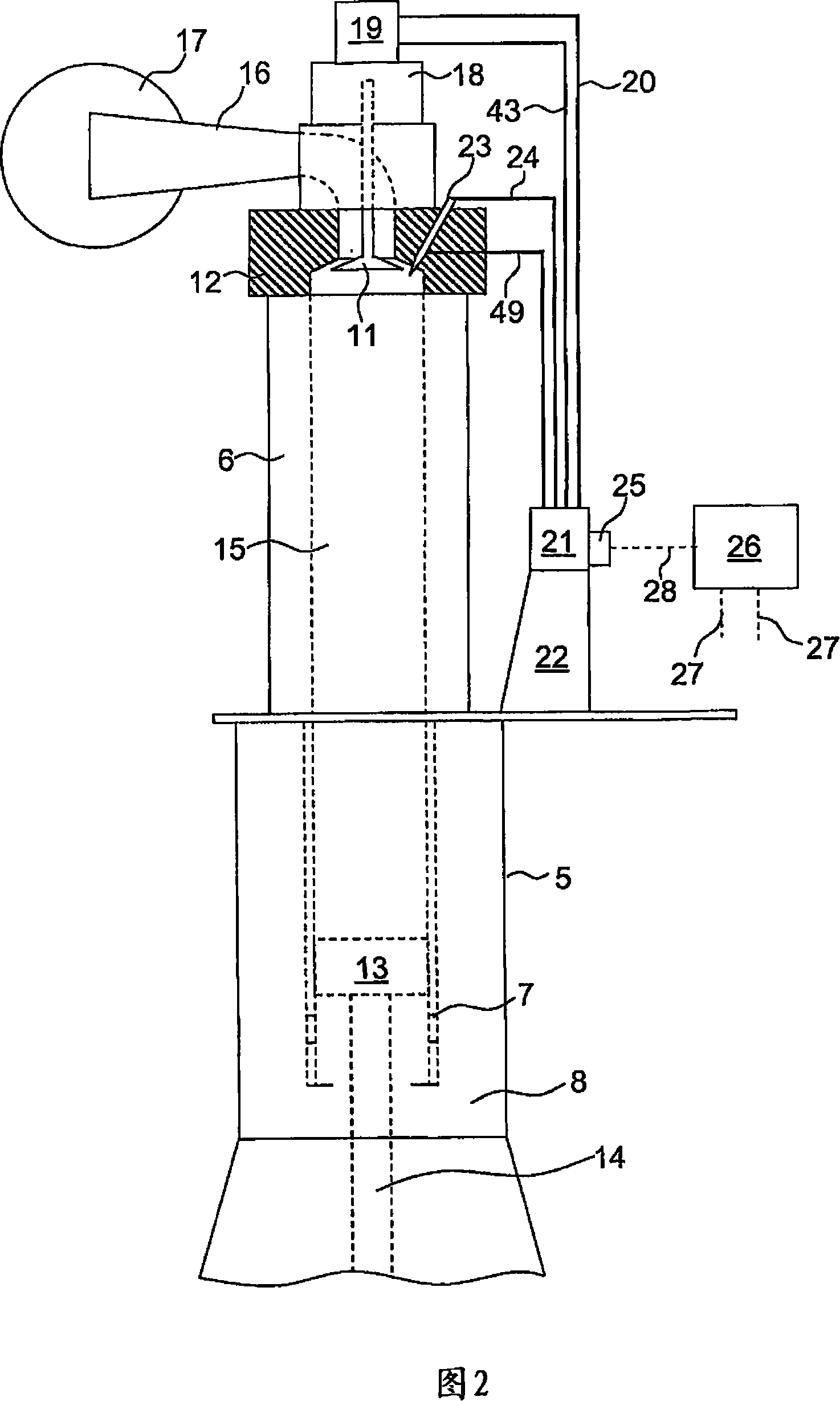

[0071] FIG. 2 shows the cylinder 6 of the internal combustion engine. The cylinder 6 is of the unidirectional flow type and has an exhaust port 7 in an air box 8 which is supplied with exhaust gas supercharged by a turbocharger 10 ( FIG. 1 ) from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com