Working electrolyte for wide temperature high voltage aluminium electrolytic capacitor and method for making same thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of easy precipitation of boric acid, large loss tangent value of capacitors, and easy swelling of capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

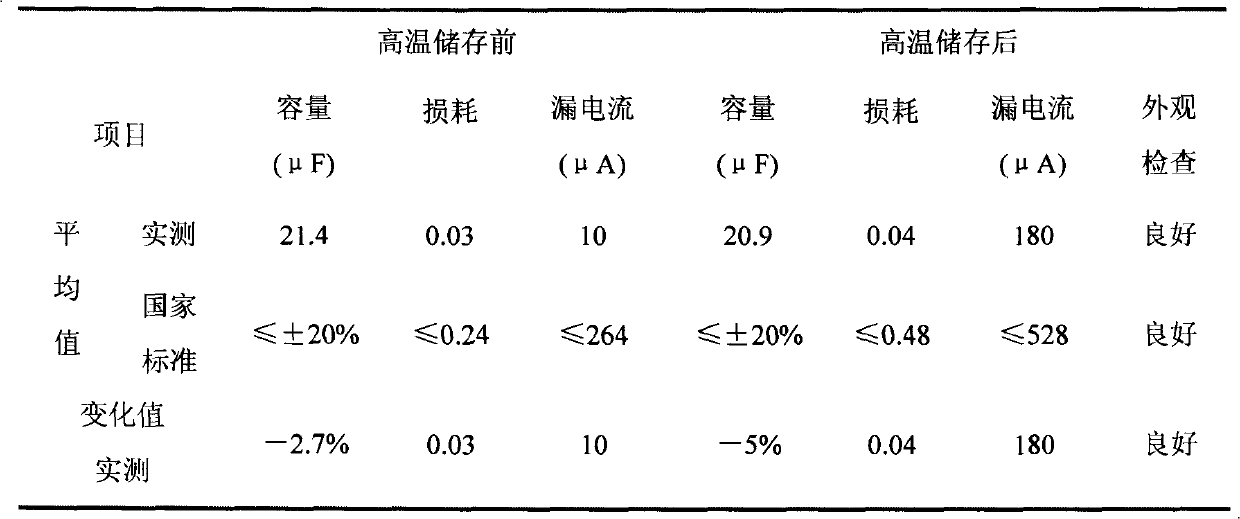

[0017] The ratio of each raw material is shown in Table 1.

[0018] Each raw material component of table 1 embodiment 1

[0019]

[0020] 1) Mix ethylene glycol, γ-butyrolactone, and water evenly, and heat to 60°C;

[0021] 2) Add ammonium sebacate, sebacic acid, ammonium dihydrogen phosphate, citric acid, p-nitrobenzoic acid, polyethylene glycol to the above mixed solvent, and stir evenly;

[0022] 3) Heat the obtained mixture to 110°C, and keep the above temperature for 30 minutes after the raw materials are fully dissolved;

[0023] 4) Add ammonium isosebacate to the above mixture, keep it warm for 15 minutes, then stop heating, and let it cool naturally in the air to obtain a working electrolyte for wide temperature and high voltage aluminum electrolytic capacitors.

Embodiment 2

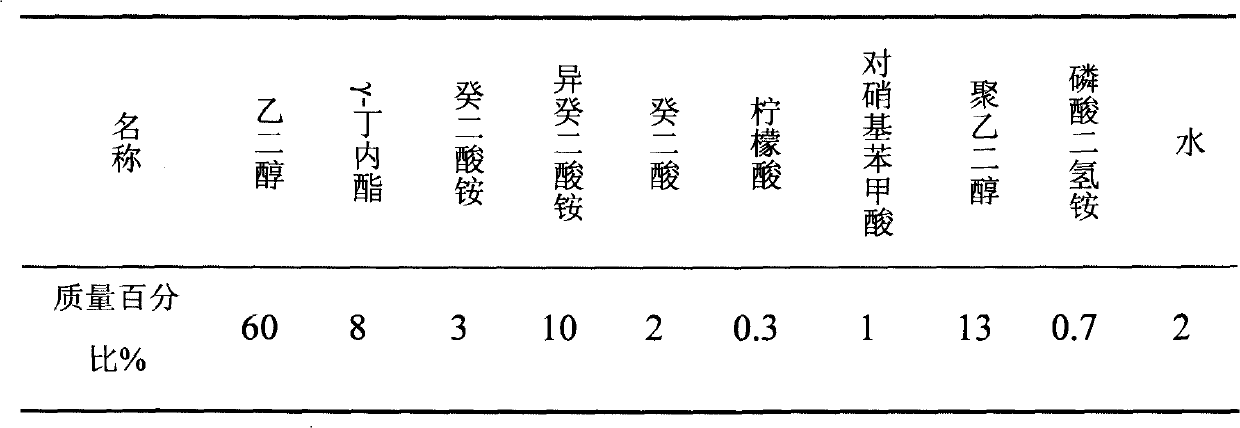

[0025] The ratio of each raw material is shown in Table 2.

[0026] The composition of each raw material of table 2 embodiment 2

[0027]

[0028] 1) Mix ethylene glycol, γ-butyrolactone, and water evenly, and heat to 90°C;

[0029] 2) Add ammonium sebacate, sebacic acid, ammonium dihydrogen phosphate, citric acid, p-nitrobenzoic acid, polyethylene glycol to the above mixed solvent, and stir evenly;

[0030] 3) Heat the obtained mixture to 120°C, and keep the above temperature for 30 minutes after the raw materials are fully dissolved;

[0031] 4) Add ammonium isosebacate to the above mixture, keep it warm for 10 minutes, then stop heating, and let it cool naturally in the air to obtain a working electrolyte for wide temperature and high voltage aluminum electrolytic capacitors.

Embodiment 3

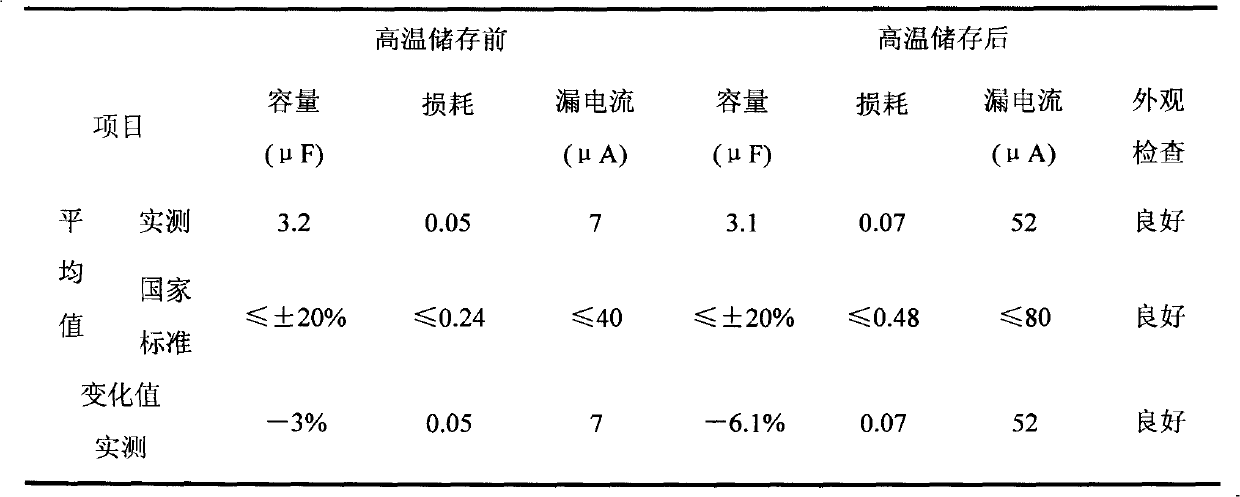

[0033] The ratio of each raw material is shown in Table 3.

[0034] The composition of each raw material of table 3 embodiment 3

[0035]

[0036] 1) Mix ethylene glycol and γ-butyrolactone evenly and heat to 90°C;

[0037] 2) Add ammonium sebacate, ammonium dihydrogen phosphate, citric acid, p-nitrobenzoic acid, polyethylene glycol to the above mixed solvent, and stir evenly;

[0038] 3) Heat the obtained mixture to 140°C, and keep the above temperature for 10 minutes after the raw materials are fully dissolved;

[0039] 4) Add ammonium isosebacate to the above mixture, keep it warm for 30 minutes, then stop heating, and let it cool naturally in the air to obtain a working electrolyte for wide temperature and high voltage aluminum electrolytic capacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com