A method for preparing cellulose nanofibers

A nanofiber and cellulose technology, applied in the field of preparation of cellulose nanofibers, can solve the problems of high energy consumption, high price, small molecular weight of cellulose, etc., and achieve the effects of uniform oxidation effect, improved utilization rate and low degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Preparation of bleached bagasse pulp

[0042] Take the sulfite bagasse pulp and wash it to neutral with distilled water. The preparation mass fraction is 0.5% NaClO 2 (sodium chlorite) solution, adding NaClO to the pulp 2 solution until the pulp is completely submerged. NaClO impregnated with pulp 2 Acetic acid solution was added to the solution to adjust the pH of the system to below 5. Then place the whole system in a 70°C water bath for 2 hours, during which intermittent stirring is performed every 15-20 minutes. After bleaching, the bleached pulp was washed with distilled water until neutral to obtain bleached bagasse pulp, which was stored in a refrigerator at 4°C.

Embodiment 2

[0043] Example 2: Oxidation of pulp cellulose by laccase-TEMPO system

[0044] Configure 0.1mol / L citric acid-sodium citrate buffer. Weigh 5mM TEMPO and dissolve it in citric acid-sodium citrate buffer to configure TEMPO solution. Weigh 1 g of bleached bagasse pulp in dry weight and add it to the TEMPO solution, and add 100 U of laccase (from Trametes versicolor) to the system. Place it open at room temperature, and stir continuously at a speed of 200 rpm. After reacting for 130h, the stirring was stopped. Centrifuge the reaction system at 10,000 rpm for 8 minutes, pour the supernatant into a reagent bottle for collection, add distilled water to the insoluble matter and continue centrifuging for 7 times, and collect the water-insoluble matter, which is the oxidized cellulose of the laccase-TEMPO oxidation system. The carboxyl content of the oxidized cellulose was determined to be 0.365 mmol / g cellulose. After the oxidation, the activity of laccase contained in the system w...

Embodiment 3

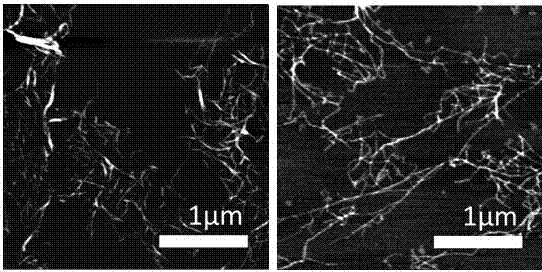

[0045] Embodiment 3: laccase-TEMPO system oxidation pulp cellulose

[0046] Configure 0.1mol / L citric acid-sodium citrate buffer. Weigh 5mM TEMPO and dissolve it in citric acid-sodium citrate buffer to configure TEMPO solution. Weigh 1 g of bleached bagasse pulp in dry weight and add it to the TEMPO solution, and add 1000 U of laccase (from Trametes versicolor) to the system. Place it open at room temperature, and stir continuously at a speed of 200 rpm. After 24 h of reaction, the stirring was stopped. Centrifuge the reaction system at 10,000 rpm for 8 minutes, pour the supernatant into a reagent bottle for collection, add distilled water to the insoluble matter and continue centrifuging for 7 times, and collect the water-insoluble matter, which is the oxidized cellulose of the laccase-TEMPO oxidation system. The carboxyl content of the oxidized cellulose was determined to be 0.637 mmol / g cellulose. After the oxidation, the activity of laccase contained in the system was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com