Method for extracting toasted garlic amylase from toasted garlic finely processing waste-water

A garlic polysaccharide and deep processing technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of pollution, high cost, waste of useful substances, etc., and achieve the effect of reducing production costs and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

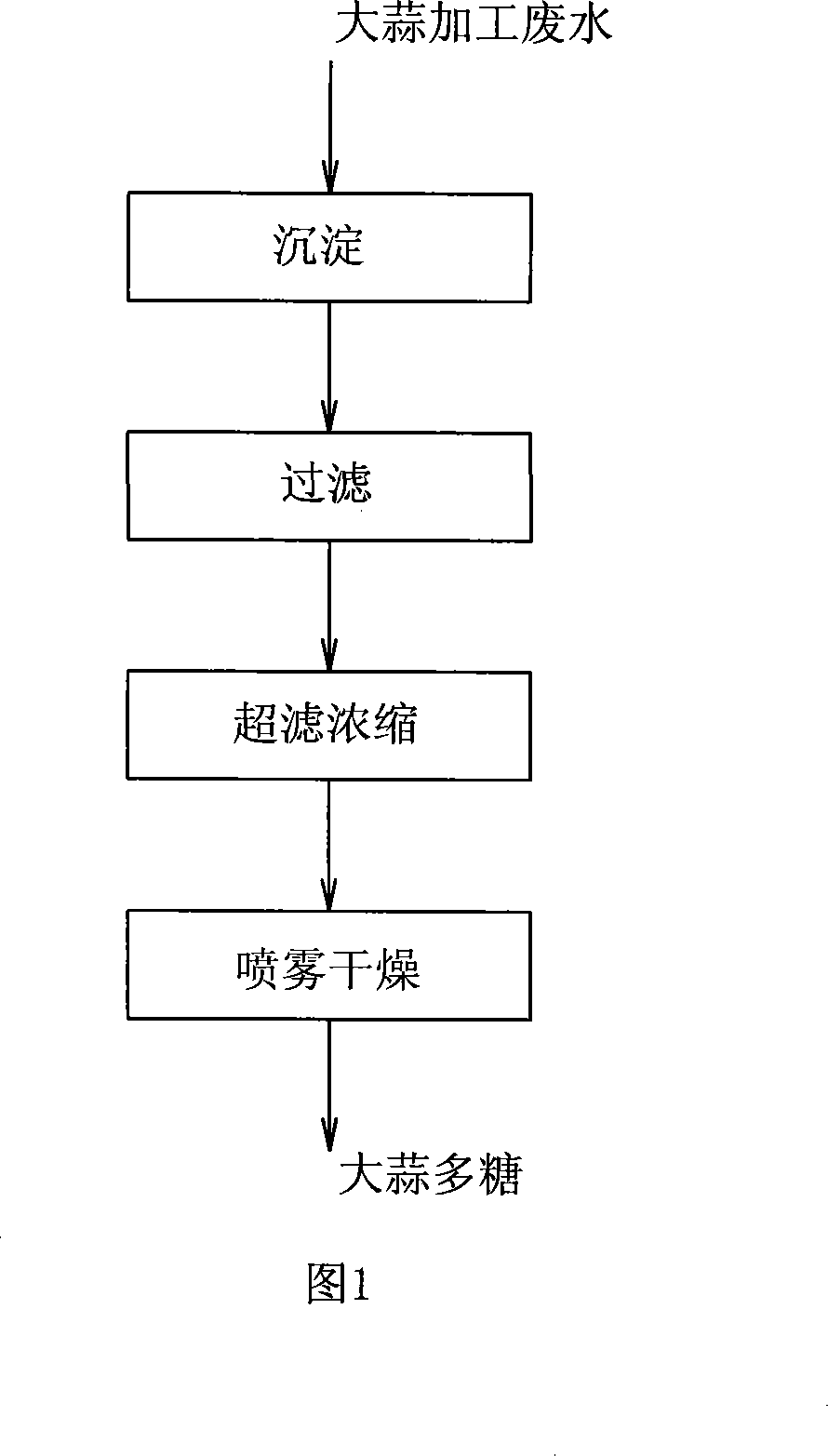

Method used

Image

Examples

preparation Embodiment 1

[0024] Raw materials: 1000Kg of garlic washing waste water;

[0025] Ultrafiltration device: the molecular weight cut-off of the membrane is 67000 and 3500 respectively; the material of the membrane is polysulfone (PSF); the operating pressure is 0.3MPa.

[0026] Spray drying tower: The spray feeding pressure is 0.2MPa, the temperature of the inlet of the spray tower is 150°C; the temperature of the outlet of the spray tower is 85°C.

[0027] Process steps:

[0028] 1. Collect 1000kg of garlic deep-processing wastewater, and let it settle naturally for 5 hours. The supernatant is filtered through a 5um cloth bag filter to filter out large particles of impurities and then sent to the concentration tank;

[0029] 2. Use an ultrafiltration device with a molecular weight cut-off of 67,000 to intercept and concentrate the filtrate in the concentration tank to obtain 5 kg of garlic polysaccharide concentrate CW1. The solid content in the concentrate is 7%, and the clarified permeat...

preparation Embodiment 2

[0034] Raw materials: garlic powder washing wastewater 1000Kg;

[0035] Ultrafiltration device: the molecular weight cut-off of the membrane is 70000 and 4000 respectively; the material of the membrane is polyimide (PI); the operating pressure is 0.2MPa.

[0036] Spray drying tower: The spray feeding pressure is 0.3MPa, the inlet temperature of the spray tower is 145°C; the outlet temperature is 85°C.

[0037] Process steps:

[0038] 1. Collect 1000kg of garlic powder washing wastewater, let it settle naturally for 5 hours, filter the supernatant through a plate and frame filter, and send it into the concentration tank after filtering out large particles of impurities;

[0039] 2. Utilize an ultrafiltration device with a molecular weight cut-off of 70,000 to intercept and concentrate the filtrate in the concentration tank to obtain 5.9 kg of garlic polysaccharide concentrate CW1. The solid content in the concentrate is 8%, and the clarified permeate filtrate is collected;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com