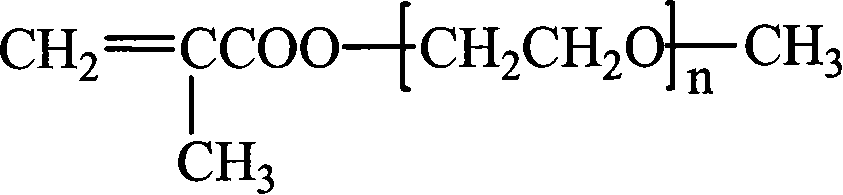

Method for synthesizing polyethylene glycol monomethyl ethermethacrylic acid esters by nitrogen with water

A technology of polyethylene glycol monomethyl ether and methacrylate, which is applied in the field of synthesis of ester compounds in organic chemistry, can solve problems such as high cost, cumbersome production process, and harmful environment, and achieve high degree of unsaturation, high reaction Good activity and high esterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 1500 parts of polyethylene glycol monomethyl ether (polymerization degree n is 23), 258 parts of methacrylic acid into the reaction kettle, add 50 parts of p-toluenesulfonic acid and 0.5 part of phenothiazine under stirring, then reflux with condensation and water separation The device is fed with nitrogen, the temperature is raised to 100°C to 140°C, the reaction is carried out for 6.5 hours, and the temperature is lowered to obtain polyethylene glycol monomethyl ether methacrylate.

Embodiment 2

[0021] Add 1537 parts of polyethylene glycol monomethyl ether (polymerization degree n is 29), 238 parts of methacrylic acid into the reaction kettle, add 17 parts of concentrated sulfuric acid and 1.7 parts of hydroquinone under stirring, and connect to the condensation reflux and water separation device , feed nitrogen gas, raise the temperature to 100°C-140°C, react for 6.0 hours, and lower the temperature to obtain polyethylene glycol monomethyl ether methacrylate.

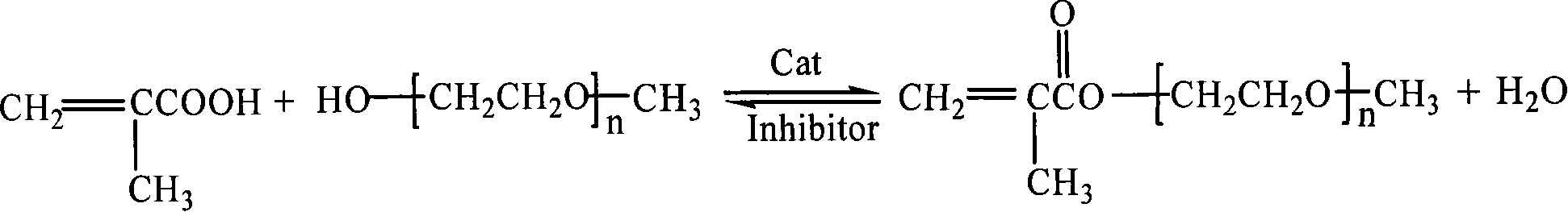

[0022] The reaction equation in the above-mentioned embodiment is:

[0023]

[0024] Note: In the formula: n=5~45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com