Organic light emitting diode

A technology of light-emitting diodes and diodes, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of increasing process steps and production costs, narrow band gap, etc. Production cost, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

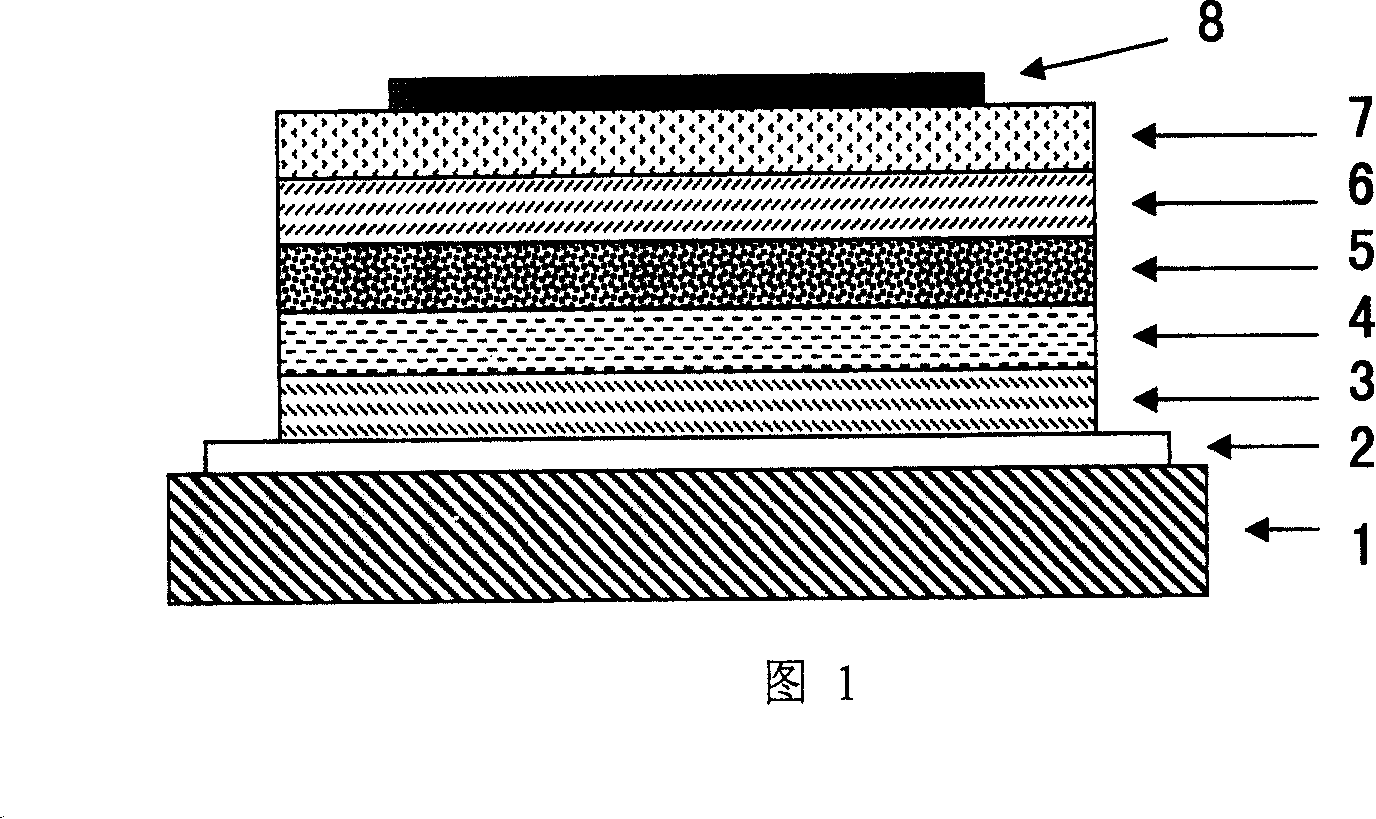

[0030] Please refer to the accompanying drawing 1, firstly, ITO is etched on the substrate 1 with ITO to form the anode 2, then the ITO is pretreated with oxygen plasma, and then copper phthalocyanine (CuPc), N, N is continuously evaporated on the ITO. -Diphenyl-N,N-di(2-naphthyl)-1,1-biphenyl-4,4-diamine (NPB), 9,10-(2-β-naphthyl)anthracene (ADN) : 3-(2-Benzothiazole)-7-diethylaminocoumarin (C6): 4-bicyclomethylene-2-tert-butyl-6-(1,1,7,7- Tetramethyljulonidine-4-vinyl)-4hydro-pyran (DCJTB), 8-hydroxyquinoline aluminum (Alq3), and lithium fluoride (LiF) were used as hole injection layer 3 and hole transport layer respectively. Layer 4, luminescent layer 5, electron transport layer 6, electron injection layer 7, and then vapor-deposit a layer of metal aluminum as the cathode 8, and finally package the device in anhydrous and oxygen-free manner to complete the device fabrication. Wherein the luminescent layer is co-evaporated from three sources, 3-(2-benzothiazole)-7-diethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com