High voltage synchronous machine whole digitization vector control device

A synchronous motor, all-digital technology, applied in vector control systems, motor generator control, control of electromechanical transmissions, etc., can solve the problems of low input power factor, low output frequency, and large input current harmonic content. The effect of a small speed ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

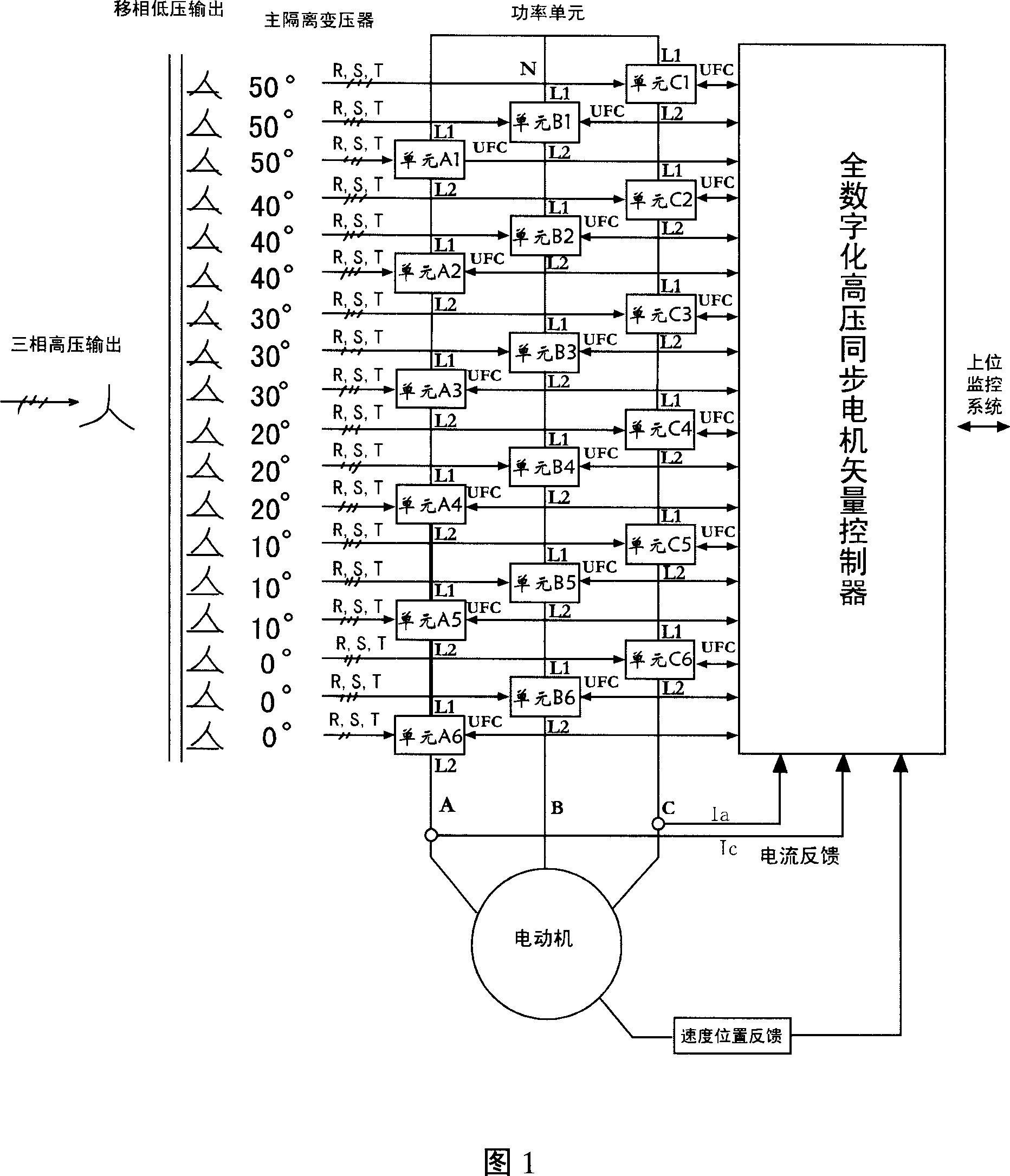

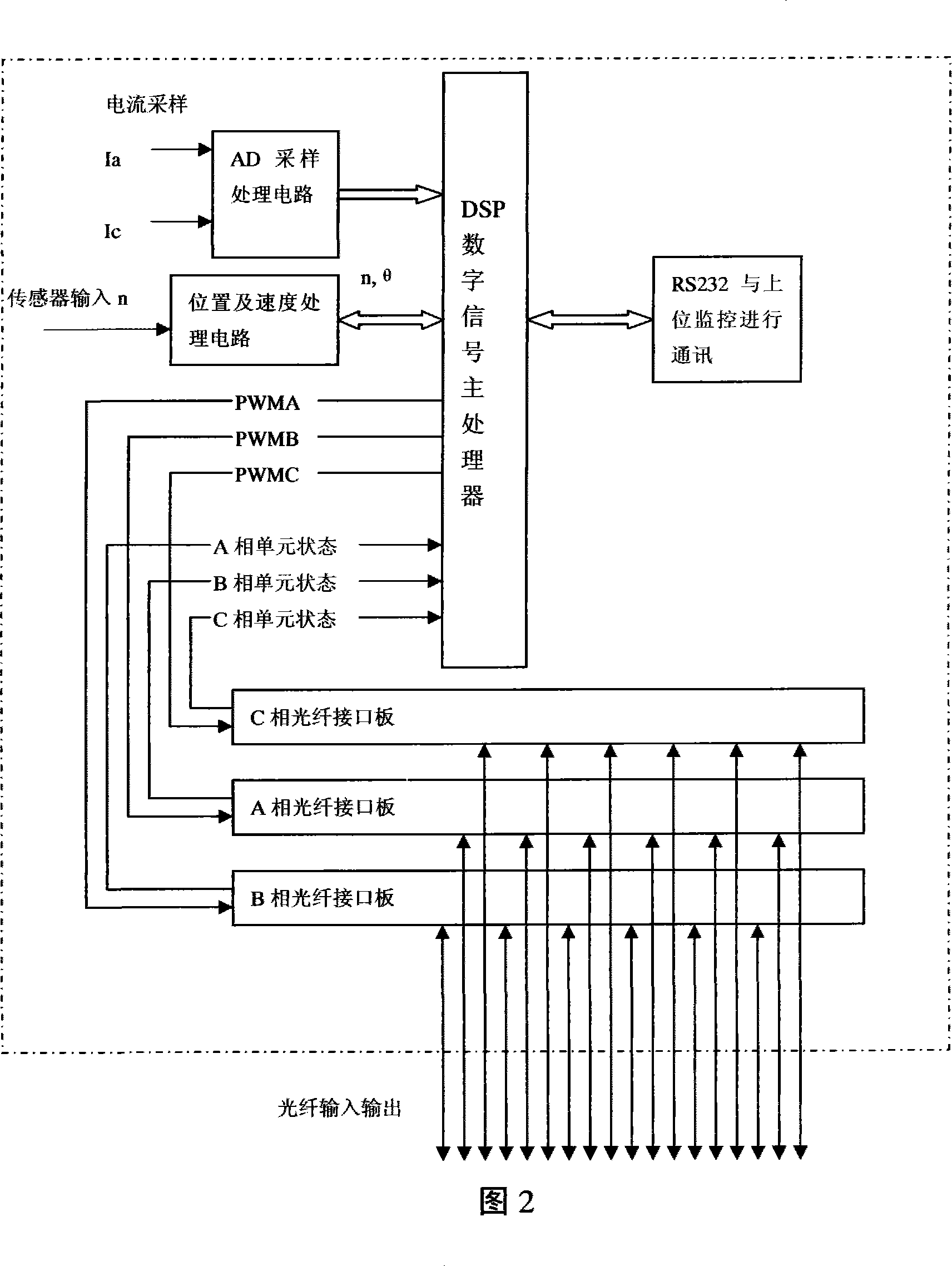

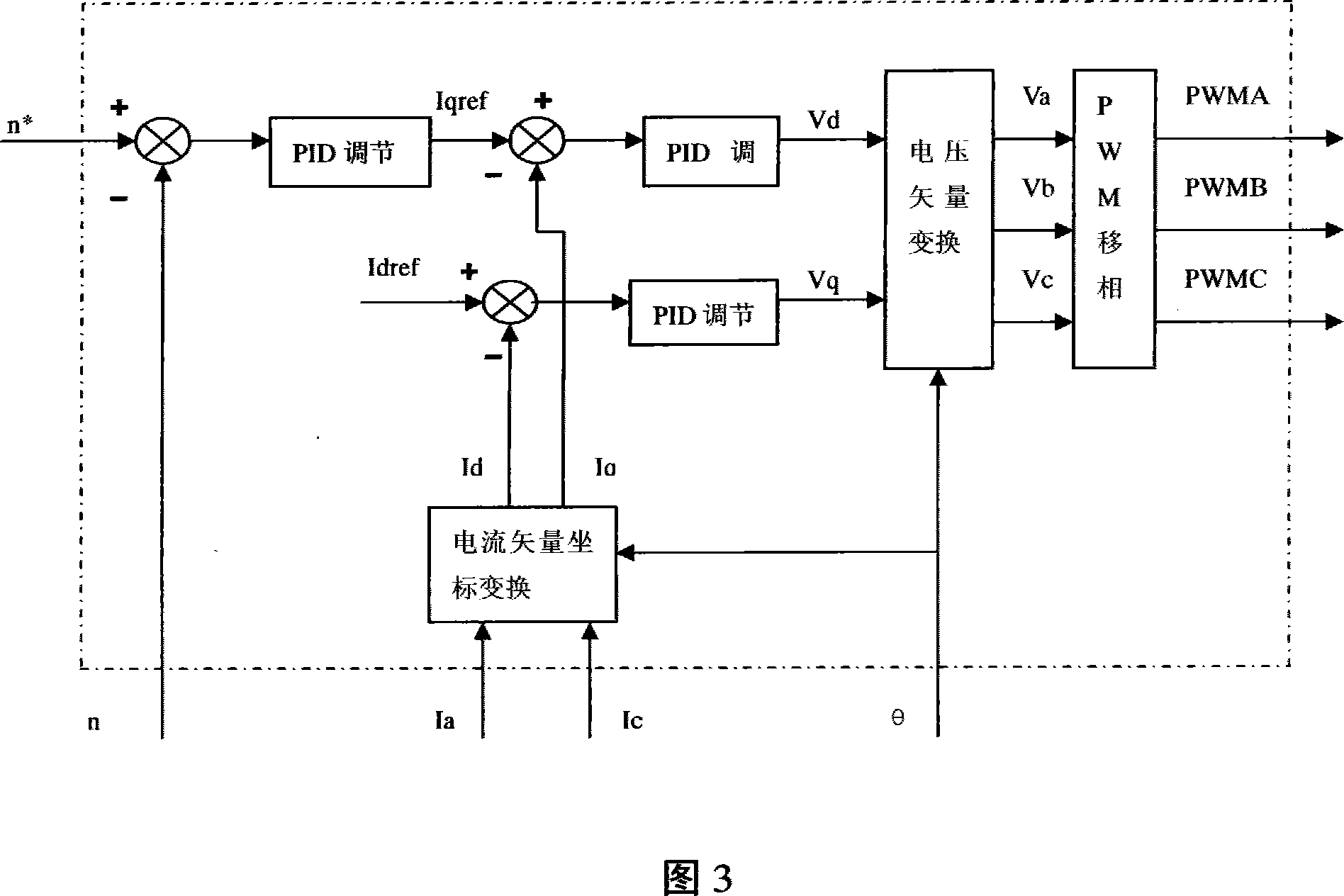

[0030] As shown in Figure 1, the full digital vector control device of the high-voltage synchronous motor of the present invention is composed of the following technical features and units. The three-phase high-voltage electrical input phase-shifting isolation transformer, after the phase-shifted isolation step-down multiple AC output, is input to the belt The power unit module for energy feedback, the power unit module is inverted and output to the synchronous three-phase motor; the position and speed sensor feedback signal installed on the three-phase motor is transmitted to the programmable logic device through the optical transmitter, and the programmable logic device After serial-parallel conversion processing, the signal is transmitted to the digital signal processing DSP for data calculation processing; the current feedback signal is sampled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com