Magnesium hydroxide, method for production thereof and flame-retarder comprising the magnesium hydroxide, and flame-retardant resin composition containing the magnesium hydroxide

A technology of magnesium hydroxide and manufacturing methods, applied in the direction of magnesium hydroxide, etc., to achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

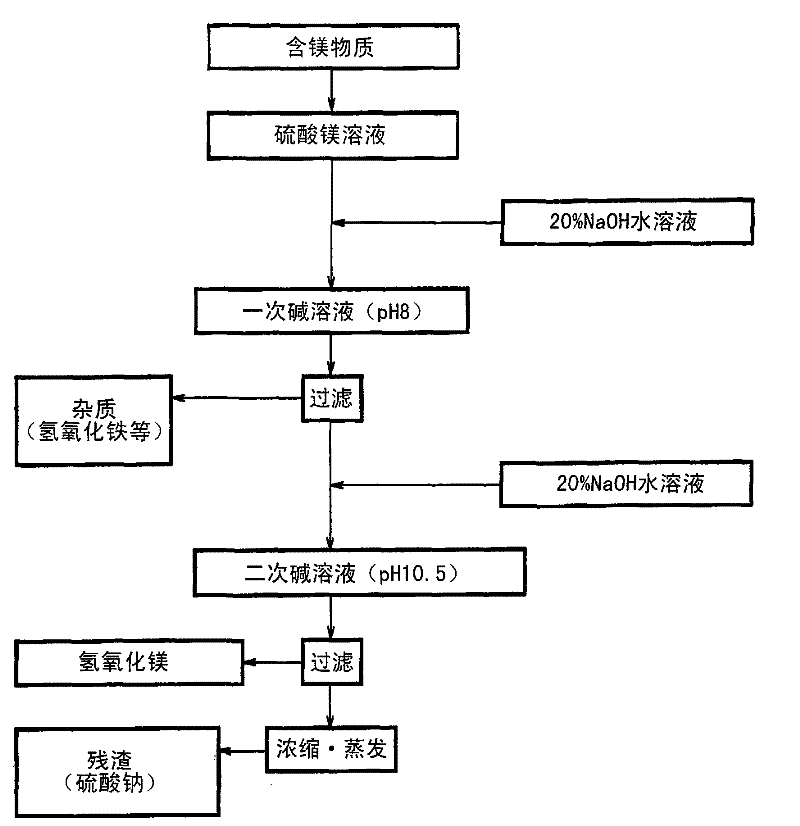

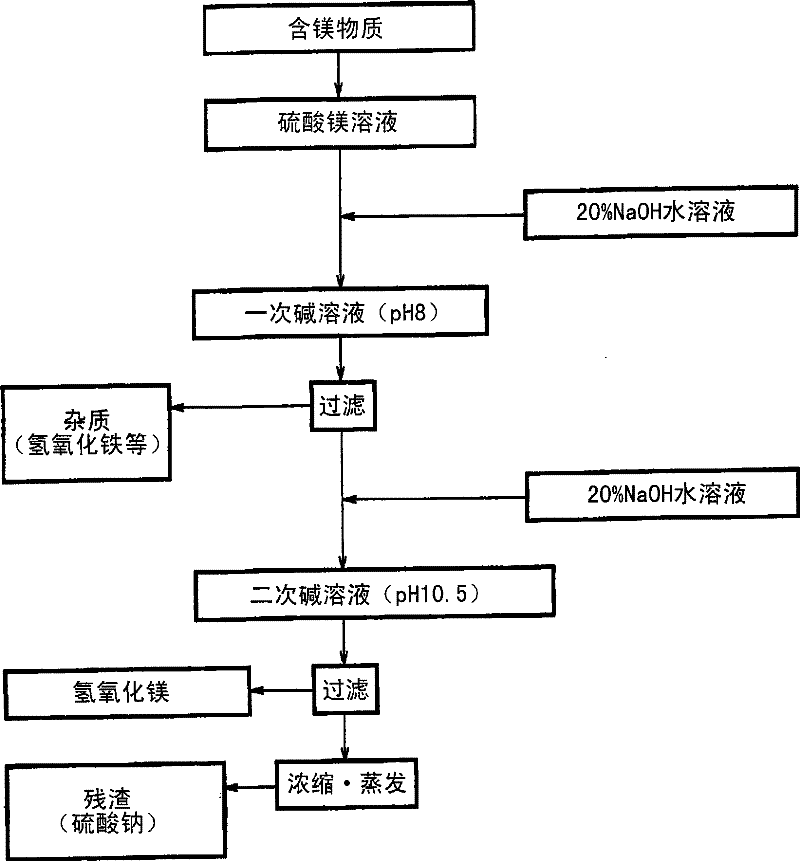

[0054] 1. Manufacture of magnesium hydroxide (refer to figure 1 flow chart)

[0055] (1) Using acid solution to chemically decompose magnesium-containing substances

[0056] The powder obtained by pulverizing and classifying serpentinite (the powder sieved through a 50-mesh sieve, with an average particle diameter of 300 microns and a BET specific surface area of 8 m 2 / g) is added in water to form a suspension, to obtain a slurry, slowly add sulfuric acid (concentration 98%) that is 15% more than the theoretical value of the sulfuric acid amount required for the dissolution of all magnesia in serpentine to this slurry, while This was stirred while heating to 100°C.

[0057] (2) filter

[0058] The above slurry was filtered to obtain magnesium sulfate solution.

[0059] (3) Preparation of primary alkaline solution

[0060] A solution in which the pH of the solution was adjusted to 8 while stirring while adding a 20% sodium hydroxide solution to the magnesium sulfate so...

Embodiment 2

[0083] (1) Recovery of asbestos

[0084] Asbestos-containing construction material (corrugated asbestos tile) waste is crushed and classified, and the contained asbestos (powder passed through a 450-micron sieve) is recovered.

[0085] (2) Using acid solution to chemically decompose magnesium-containing substances

[0086] The above-mentioned asbestos powder is immersed in water to form a suspension to obtain a slurry, and slowly add sulfuric acid (concentration 98%) that is 15% more than the theoretical value of the acid required to dissolve all the magnesium oxide in the asbestos to the slurry, while heating to 100 °C while stirring for two hours.

[0087] (3) filter

[0088] The above slurry was filtered to obtain a magnesium sulfate solution.

[0089] (4) Preparation of primary alkaline solution

[0090] The pH of the solution was adjusted to 8 while stirring while adding 20% sodium hydroxide solution to the magnesium sulfate solution. As a result, impurities (iron ...

Embodiment 3

[0113] Utilize that the serpentinite as a magnesium-containing material is pulverized and classified, and the obtained powder (the powder passed through a sieve with a mesh size of 450 microns) is used, and the same procedure as in Example 1 (refer to figure 1 The flow process) is carried out using acid solution to chemically decompose magnesium-containing substances, filter magnesium-containing slurry, prepare primary alkali solution, prepare secondary alkali solution, and recover magnesium hydroxide to obtain magnesium hydroxide in Example 3 of the present invention.

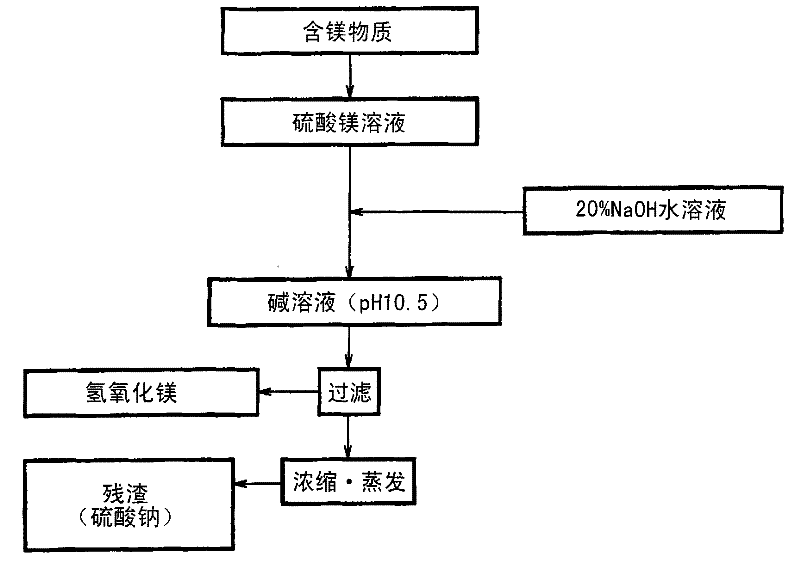

[0114] Again, for comparison with the two-stage process of the present invention, the figure 1 The manufacturing process of shown magnesium hydroxide removes the process of the preparation process of primary alkaline solution (the process without impurity removal process, refer to figure 2 process). That is to say, as the process of the comparative example, using the powder obtained by pulverizing and clas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com