Method for extracting minerals with high purity from deep ocean water

A mineral and crystallization technology, applied in solution crystallization, seawater treatment, alkali metal chloride, etc., can solve the problems of difficult effective separation and low recovery rate of mineral components, and achieve the effect of improving yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041]The deep ocean water is finely filtered with a microporous filter (material: PTFE (polytetrafluoroethylene), pore size is about 0.5 μm, manufactured by Sehan Co., Ltd.) to remove impurities (pretreatment), and then filtered with a reverse osmosis system (Doll Chemical Co., Ltd. System, FILMTEC, SW30-4021, yield: 0.5) separated into concentrated water and fresh water. The flow rates (unit: GPD) and mineral concentrations (unit: mg / l) of deep ocean water, pretreated water, and concentrated water are listed in Table 1 below, and the obtained concentrated water had a specific gravity of 4.5° Be.

[0042] Table 1

[0043] deep ocean water

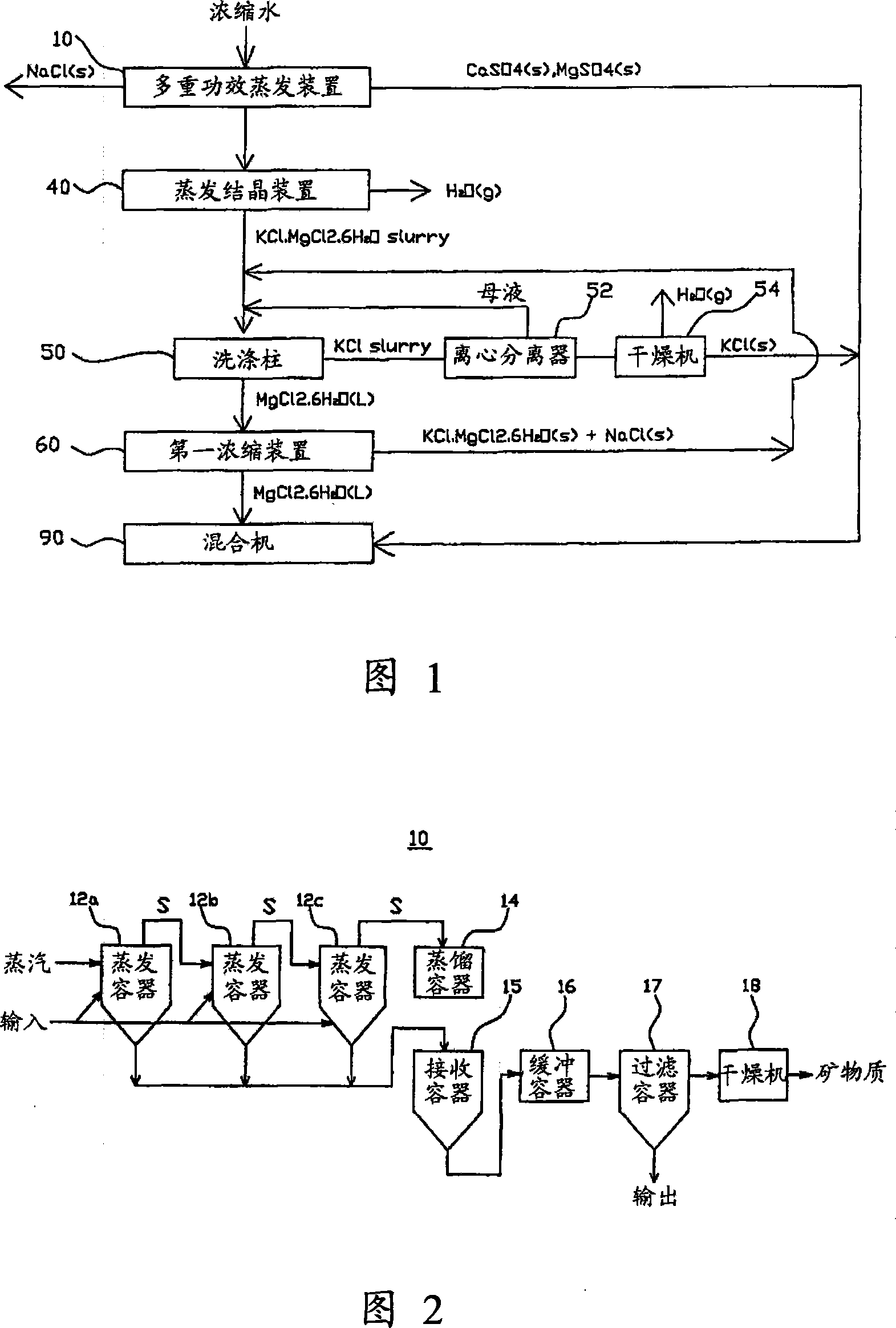

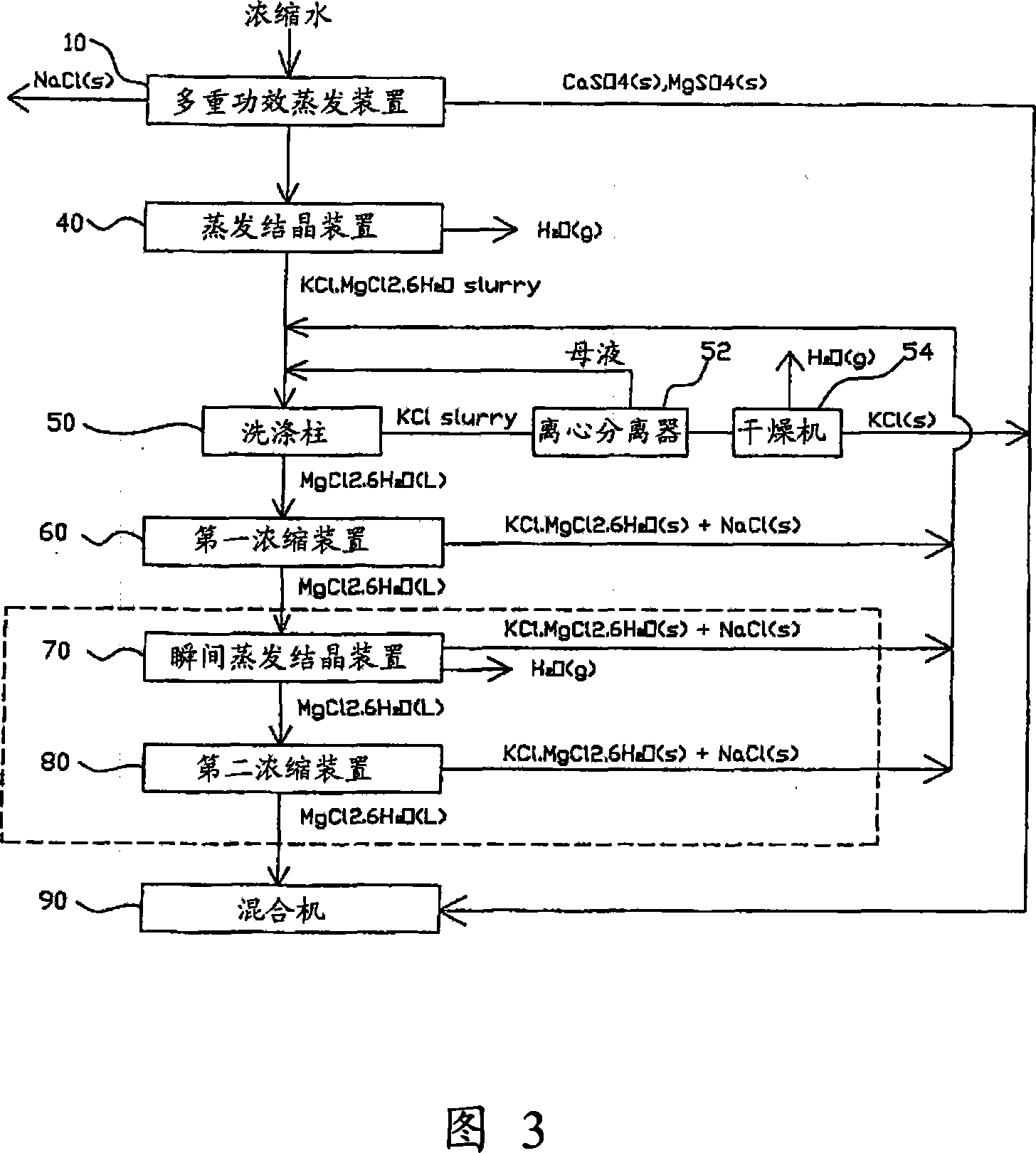

[0044] The above-mentioned concentrated water is sequentially passed through three multiple-function evaporators (10, refer to Fig. 1), while the Baume specific gravity of the concentrated water is 23 ° Be, 30 ° Be and 36 ° Be, and the calcium salt, sodium salt and sulfuric acid The salts were successively separated and remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com