Control method for preparing salvianolic acid A

A control method, the technology of salvianolic acid, applied in the control field of preparation of salvianolic acid A, can solve the problems of unstable performance, salvianolic acid A being acidic, not universal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

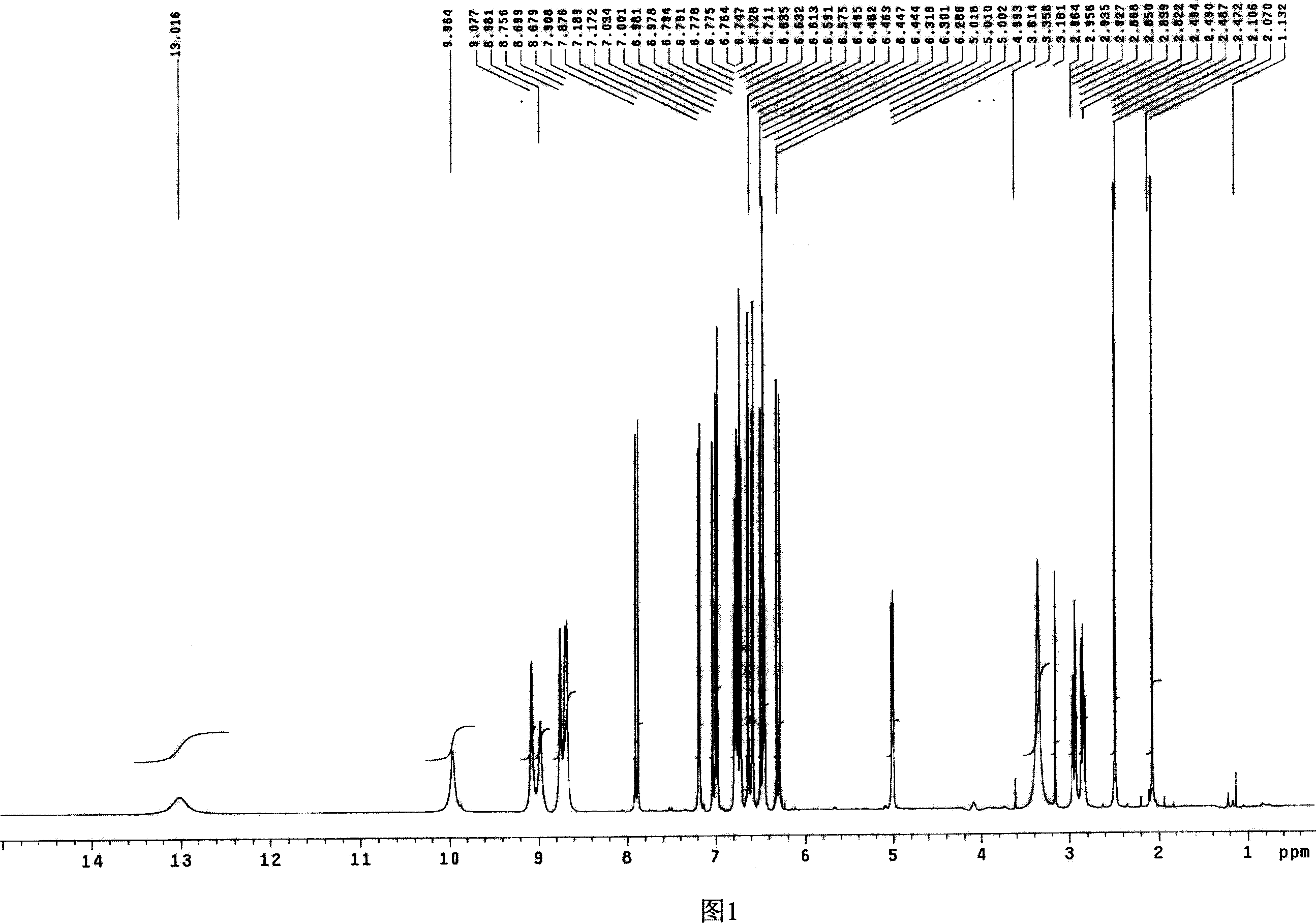

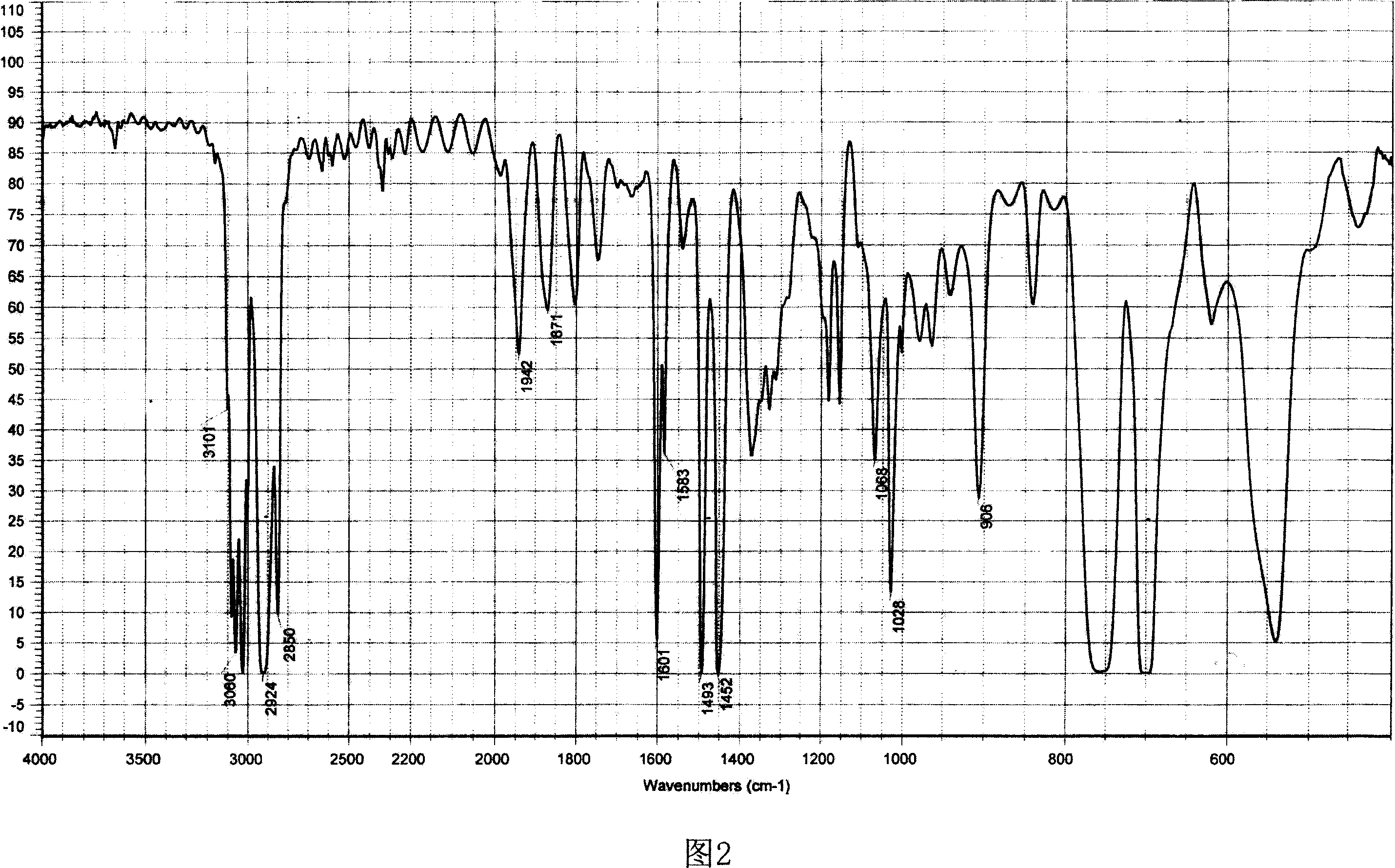

Image

Examples

Embodiment 1

[0025] Embodiment one kind of control method for preparing salvianolic acid A:

[0026] Take 250 kg of Salvia miltiorrhiza granules, add 8 times the amount of 60% ethanol for ultrasonic extraction 3 times, each time for 20 minutes, and the ultrasonic extraction temperature is 30°C. The extracts were combined, centrifuged with three legs, the centrifugate was concentrated under reduced pressure, the temperature was controlled at 60°C, and concentrated to 1:3, and the concentrated solution was placed in a reaction kettle at 120°C for 6 hours. Take the above-mentioned medicinal solution and pass it through the macroporous resin column, the ratio of the sample amount (calculated based on the dry weight of the original medicinal material) to the macroporous resin is 1:5, first wash with 10 times the column volume of water to remove impurities, and then wash with 10 times the column volume concentration Rinse with 20% ethanol water to remove impurities, then rinse with 40% ethanol w...

Embodiment 2

[0027] Example 2 A control method for preparing salvianolic acid A: basically the same as in Example 1, the difference is that the pH value is adjusted to 4 with potassium hydroxide solution to obtain salvianolic acid A.

Embodiment 3

[0028] Example 3 A control method for preparing salvianolic acid A: basically the same as Example 1, the difference is that the pH value is adjusted to 5 with ammonia water to obtain salvianolic acid A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com