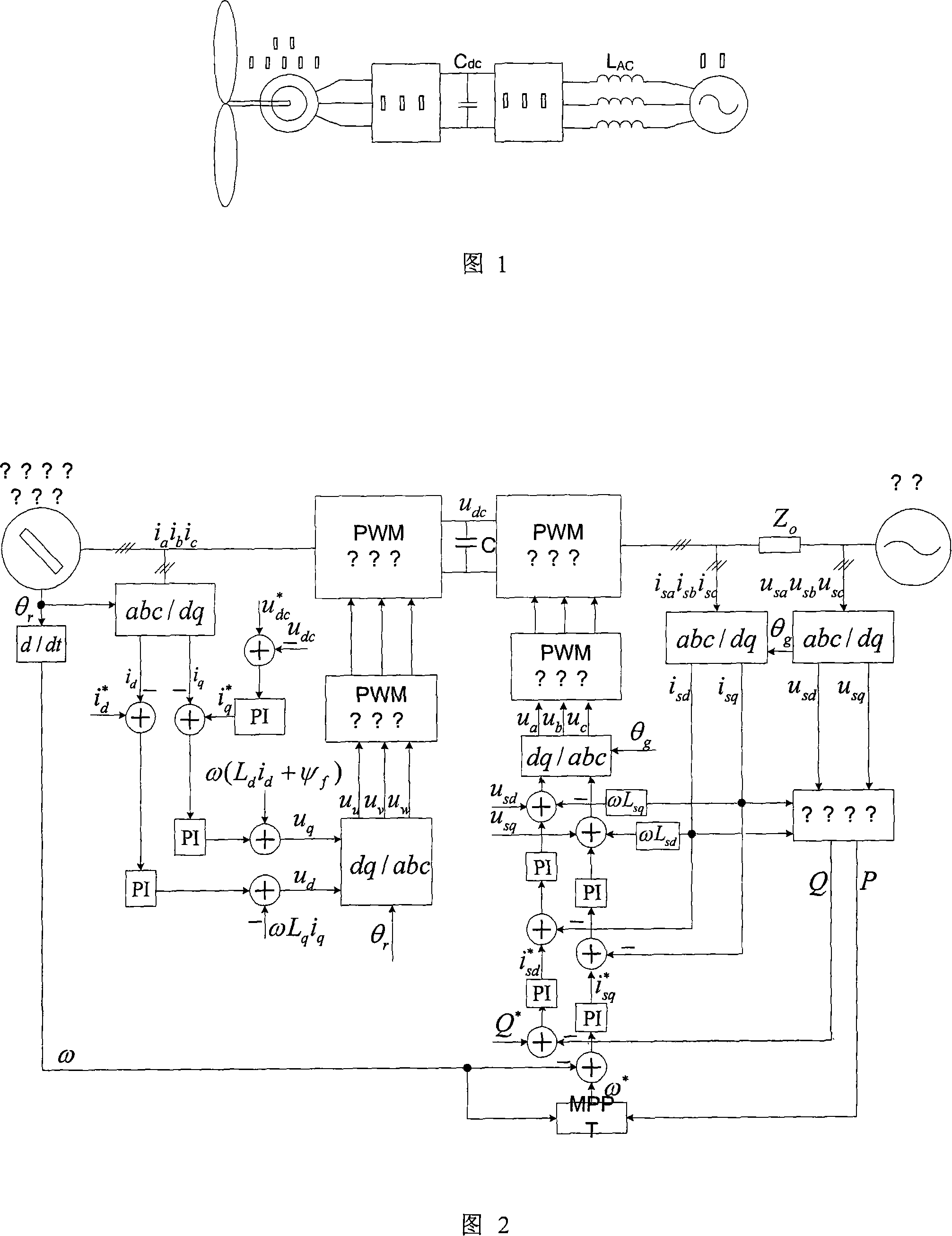

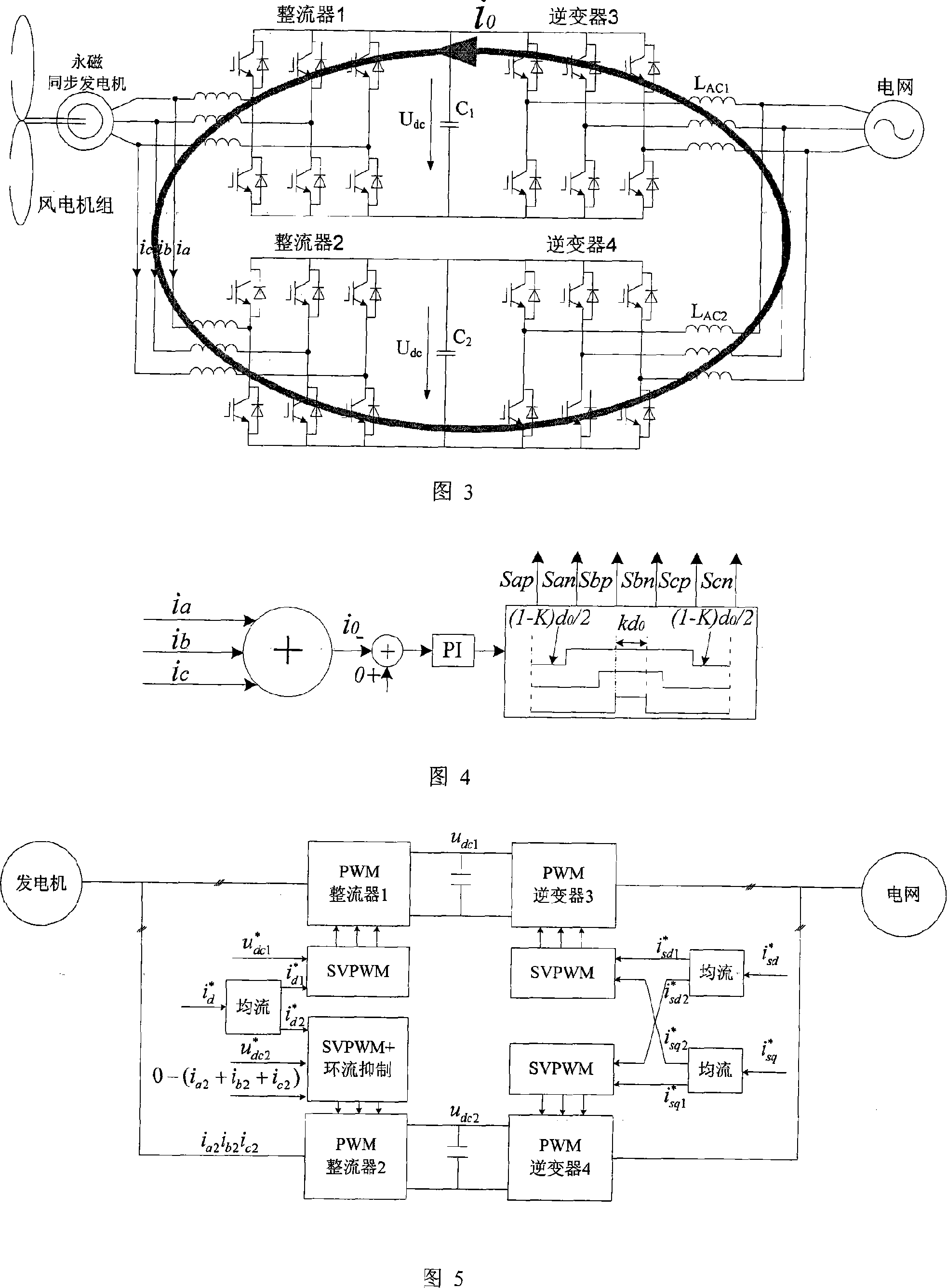

Rear change converter of wind power generation system and its loop current control method

A technology of back-to-back converters and wind power generation systems, which is applied in wind power generation, single-grid parallel feeding arrangement, etc., can solve the problems of large volume and high cost, improve operational reliability, save costs, and reduce circuit volume. and the effect of switching losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The working principle and process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] When the wind power generation system involved in the present invention is in operation, there are mainly three working states according to the size of the external wind speed:

[0028] (1) When the wind speed is lower than the rated wind speed of the system, the pitch angle is basically unchanged to maintain the maximum wind energy utilization coefficient. According to the maximum power algorithm, the system obtains the maximum power input to the grid by the system, and thus obtains the optimal speed of the generator. By adjusting the active current of the grid-connected inverter, the output power of the system is maximized, and the motor runs at the optimal speed. Generally, the reactive power is set to zero, which makes the system work at the maximum active power output state and improves the efficiency of the system. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com