Method for preparing sodium L-aspartate by bio-enzyme

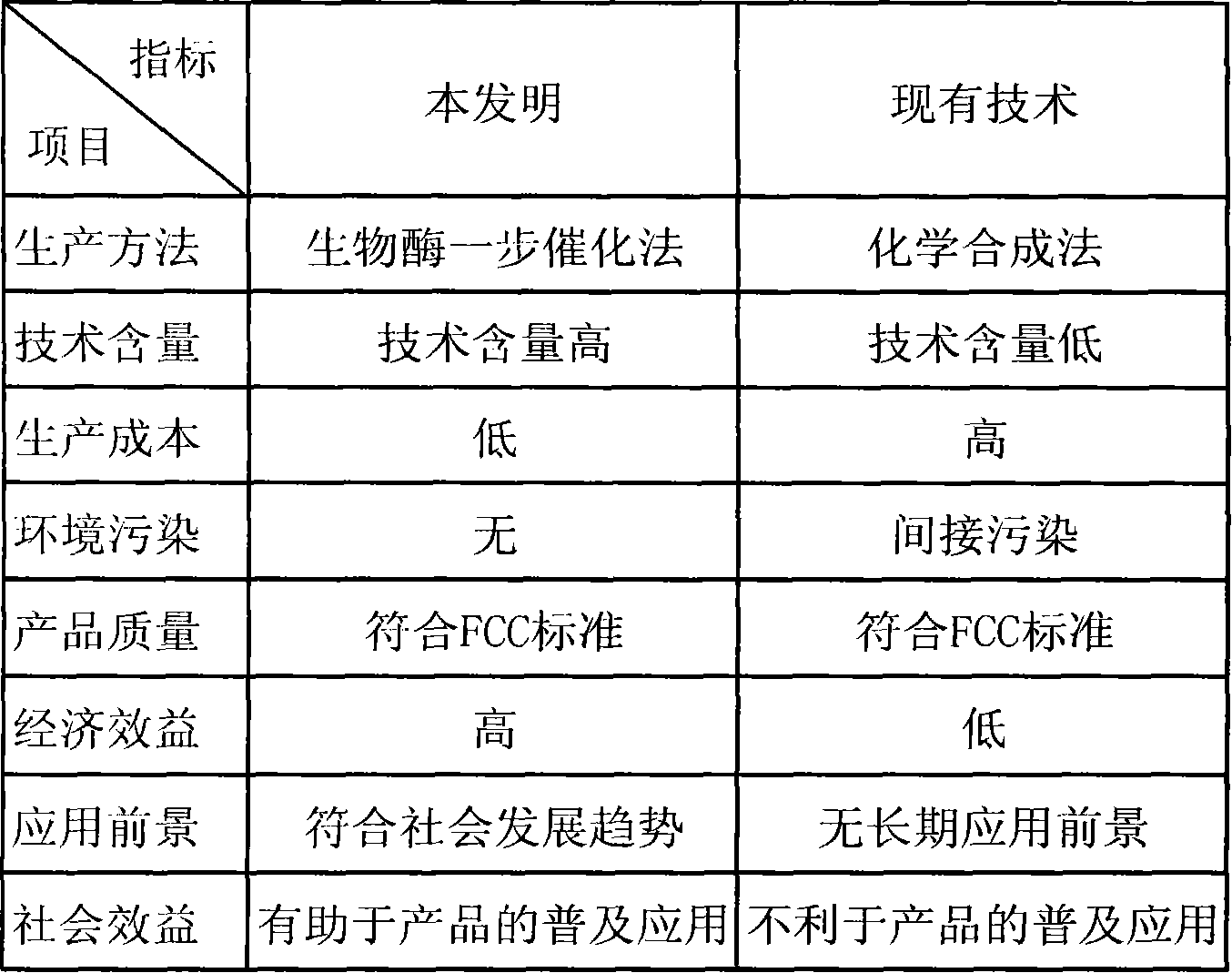

A technology of sodium aspartate and aspartase, which is applied in the field of preparing sodium L-aspartate, can solve the problems of high production cost, environmental pollution, and high price of L-aspartic acid, and achieve production cost Low, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

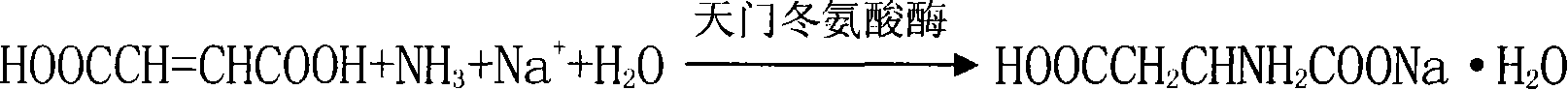

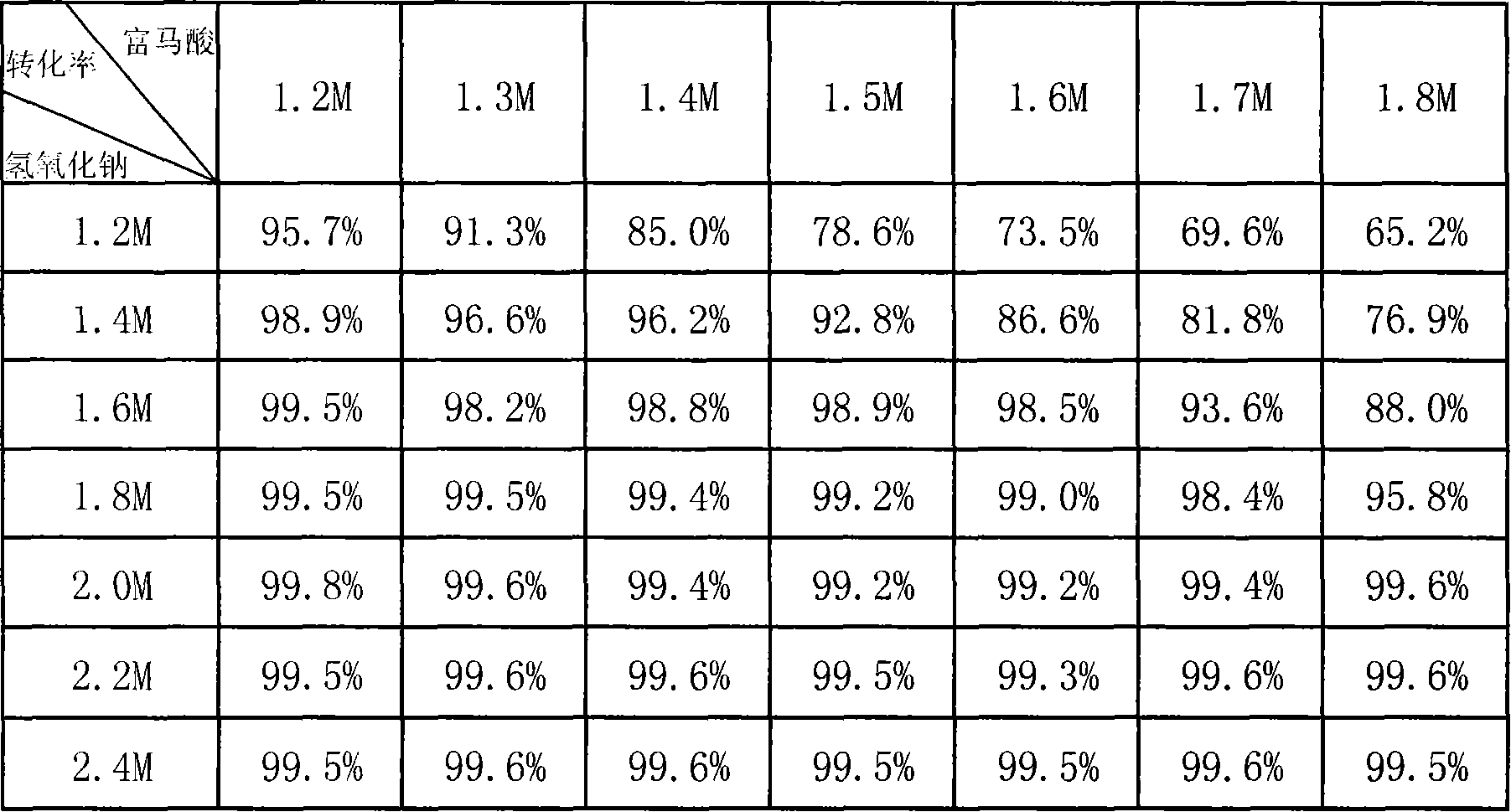

[0010] Known by reaction equation of the present invention, the molar concentration ratio of fumaric acid, sodium hydroxide and ammonia should be 1: 1: 1, but in actual production process, in order to improve the conversion rate of fumaric acid, often increase sodium hydroxide and The amount of ammonia, but the amount of the two increases too much and it will cause waste and difficulty in separating L-sodium aspartate, so the molar concentration ratio of fumaric acid, sodium hydroxide and ammonia is controlled at 1:1:1~ 1:2:2, as a preferred version of the present invention, the molar concentration ratio of fumaric acid, sodium hydroxide and ammonia in the substrate solution is 9:10:10, such a ratio can make the conversion of fumaric acid The efficiency is the largest, and the residual amount of sodium hydroxide and ammonia is small, which will not cause waste, and is convenient to separate and obtain L-sodium aspartate from the reaction solution.

[0011] The pH value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com