The member for headliner on motor vehicles of multilayer structure

A lining, automotive technology, applied in vehicle components, vehicle safety arrangements, pedestrian/occupant safety arrangements, etc., to solve problems such as insufficient scratch resistance, difficulty in recycling, and irritating odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

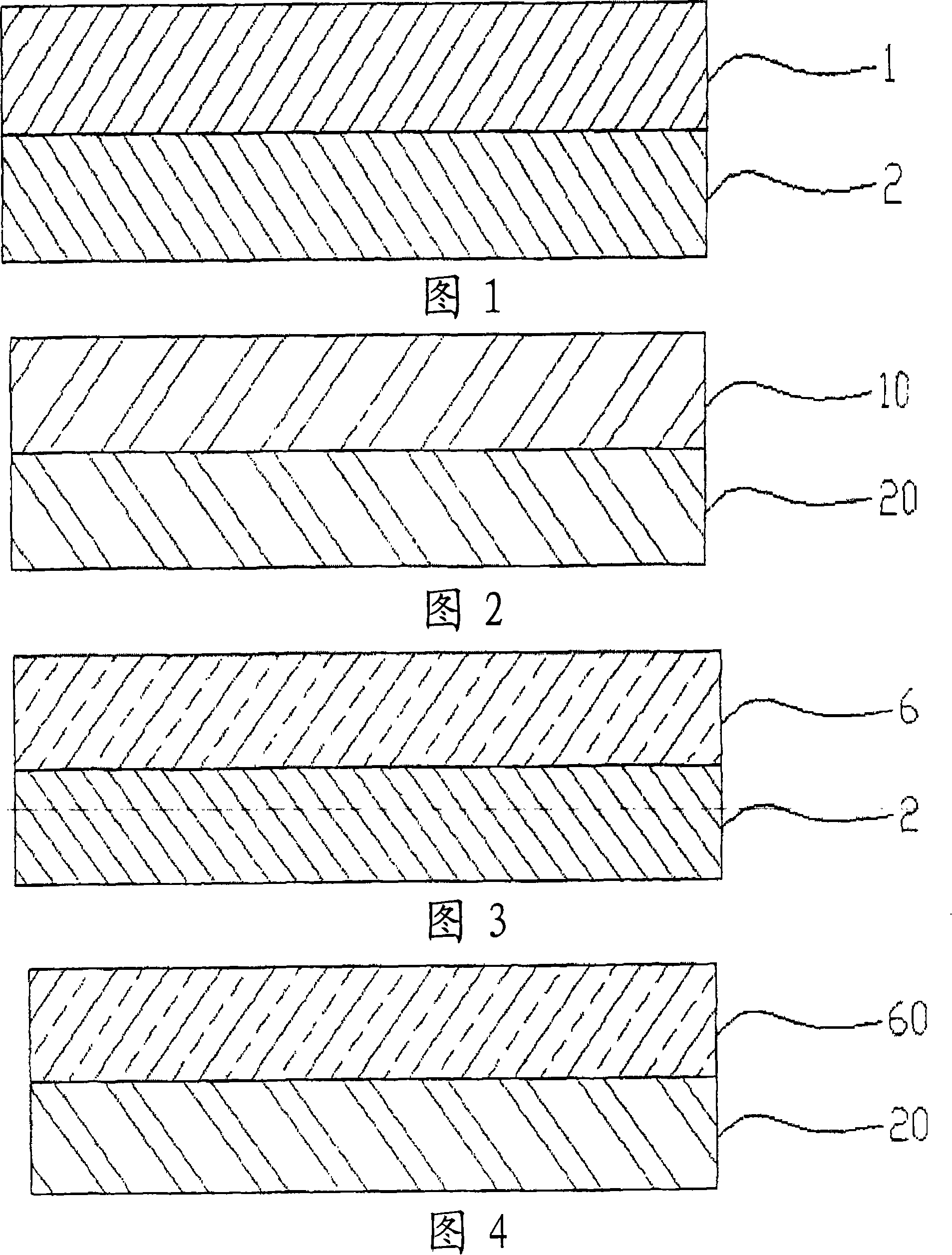

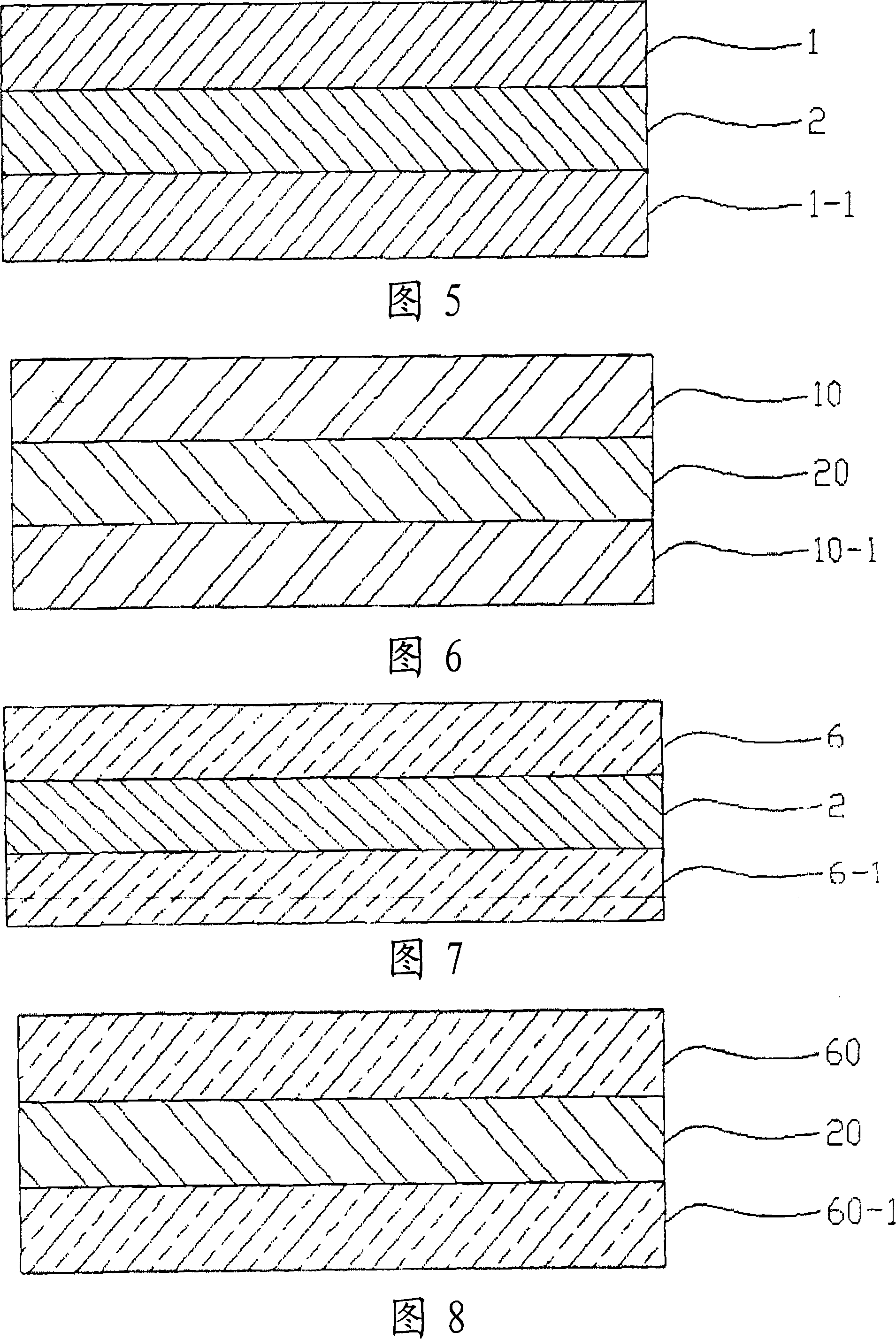

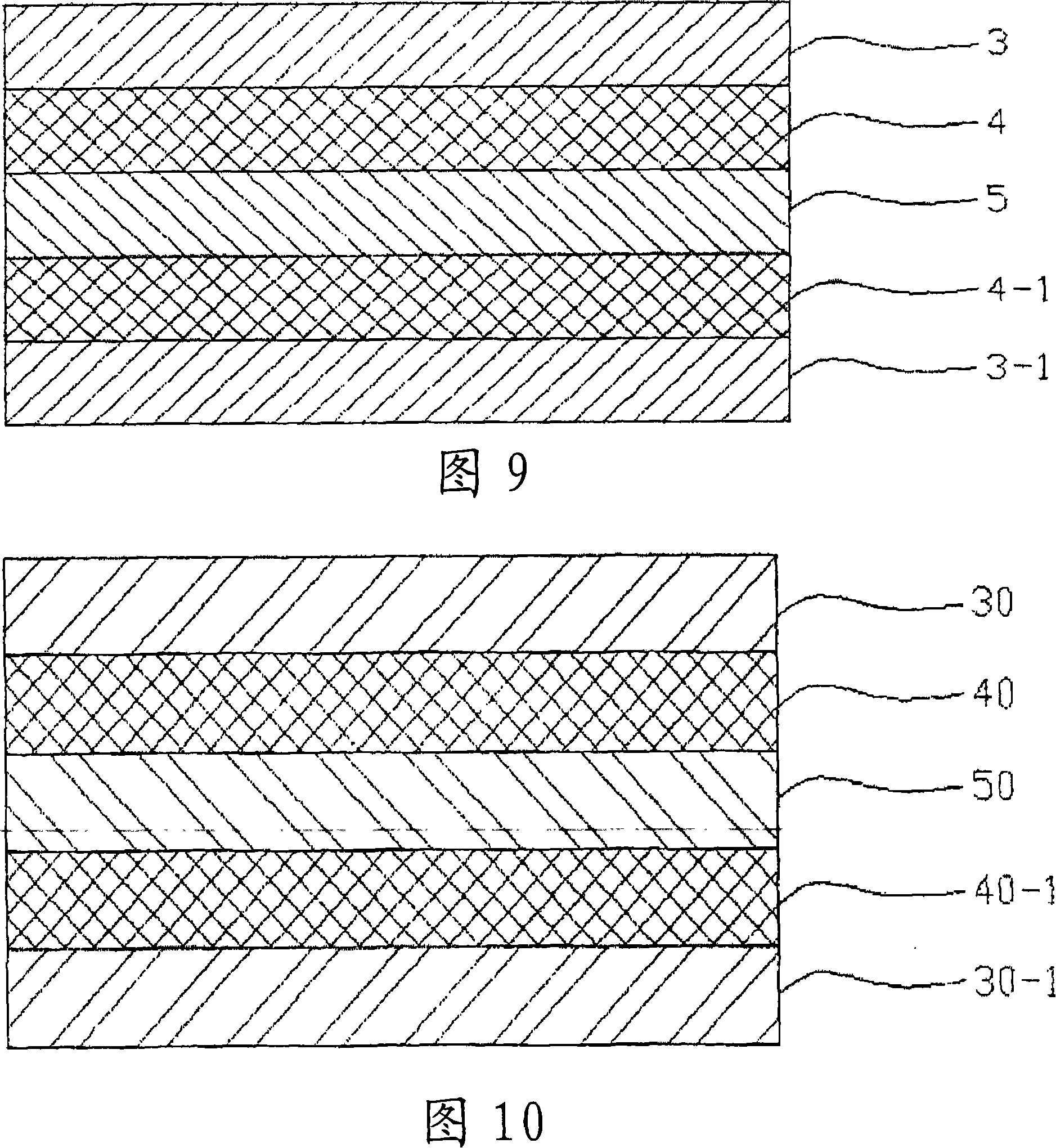

[0055] This embodiment relates to an automotive headliner having a three-layer structure consisting of a core layer and an outer layer. Both outer layers were made of shell-core bicomponent fiber (CoPET / PET; LM; commercially available from Huvis Corporation) as base fiber and conjugated hollow PET fiber (CH-PET) (commercially available from Huvis Corporation) as reinforcing fiber, and the core The layers were made of sheath-core bicomponent fibers (CoPET / PET; LM; commercially available from Huvis Corporation) as base fibers and conjugated hollow PET (CH-PET) fibers (commercially available from Huvis Corporation) as reinforcing fibers. The outer layer and the core layer are connected to each other by needling, and the bonded nonwoven fabric is produced to have 1200 g / m 2 ±5% uniform weight, and comparatively analyze the change of physical properties with the composition and content of the outer layer and the core layer. From the produced nonwoven fabric, a 6.5±0.3 mm thick aut...

Embodiment 2

[0069] The present embodiment relates to a headliner having a three-layer structure composed of an outer layer and a core layer. Both outer layers were made of sheath-core bicomponent fibers (CoPET / PET; LM; commercially available from Huvis Corporation) as base fibers and conjugated hollow PET fibers (CH-PET) (commercially available from Huvis Corporation) as reinforcing fibers, and The base fiber:reinforcing fiber weight ratio was 70 / 30. The core layer was made of a sheath-core bicomponent fiber (CoPET / PET; LM; commercially available from Huvis Corporation) as a base fiber and a conjugated hollow PET fiber (CH-PET) (commercially available from Huvis Corporation) as a reinforcing fiber. The base fiber:reinforcing fiber weight ratio in the core layer was 60 / 40.

[0070] The outer layer and the core layer are connected to each other by needle punching. In order to analyze the change of physical properties with the weight of the non-woven fabric comparatively, the non-woven fabr...

Embodiment 3

[0077] This embodiment relates to a vehicle headliner having a three-layer structure consisting of a core layer and an outer layer. Both outer layers were made of sheath-core bicomponent fibers (CoPET / PET; LM; commercially available from Huvis Corporation) as base fibers and conjugated hollow PET fibers (CH-PET; commercially available from Huvis Corporation) as reinforcing fibers, and the base The fiber:reinforcing fiber weight ratio was 80 / 20. The core layer was made of a sheath-core bicomponent fiber (CoPET / PET; LM; commercially available from Huvis Corporation) as a base fiber and a conjugated hollow PET fiber (CH-PET; commercially available from Huvis Corporation) as a reinforcing fiber. The base fiber:reinforcing fiber weight ratio in the core layer was 60 / 40.

[0078] The outer layer and the core layer are connected together by needling, and the connected nonwoven fabric is produced with a weight of 1217g / m 2 . From the non-woven fabric, under the same conditions as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com