Small power modularize solar cell component

A technology of solar cell components and solar cells, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as damage, waste, and component performance degradation, and achieve the effects of increasing service life, reducing waste, and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

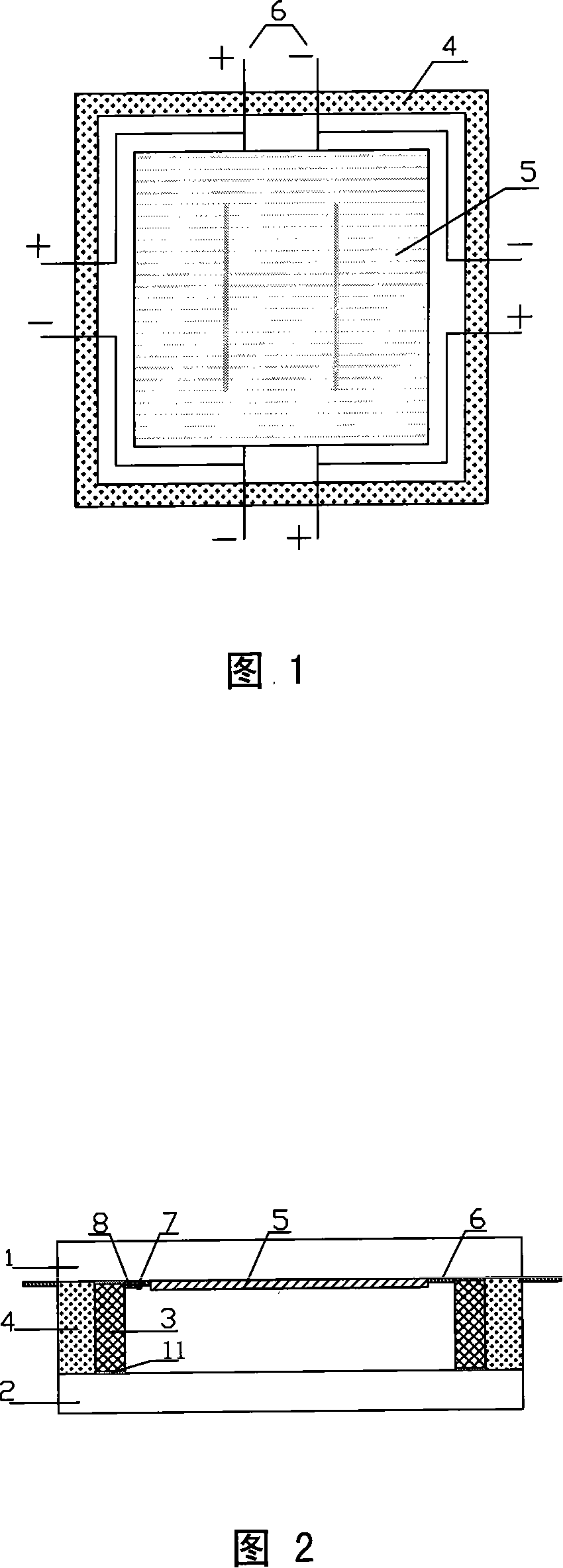

[0029] A low-power modular solar cell module as shown in Fig. 1 and Fig. 2, which includes a glass plate, a solar cell sheet 5, a bypass diode 8 and a component status display module 7 for indication, a bypass diode 8 and a component status The display modules 7 are electrically connected to the solar cells 5 respectively, and the glass plates include a top glass plate 1 and a bottom glass plate 2, and a spacer bar 3 for sealing is installed around the top glass plate 1 and the bottom glass plate 2, The spacer 3 can use aluminum spacer, stainless steel spacer, plastic spacer or some flexible spacer, spacer 3 is filled with molecular sieve desiccant or coated with glue containing molecular sieve desiccant, the spacer 3 and the top surface The glass plate 1 and the bottom glass plate 2 are all airtightly connected, and the three form a closed hollow chamber, which is filled with inert gas or evacuated, and the solar cells 5, bypass diodes 8 and component status display modules 7...

Embodiment 2

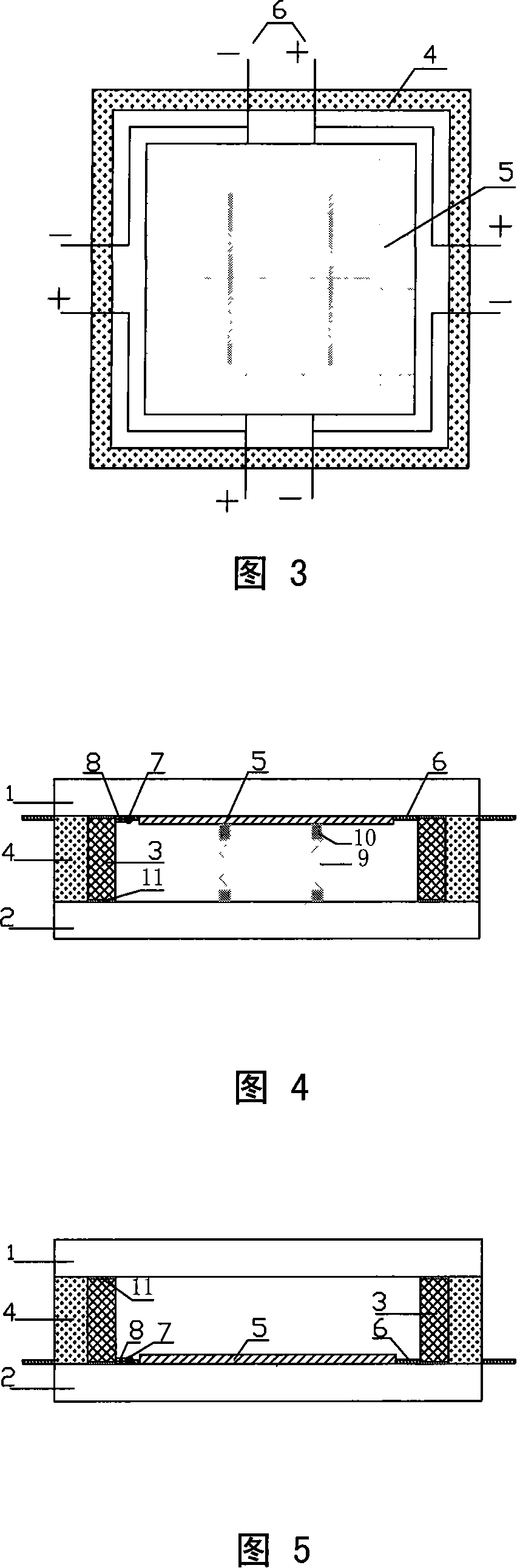

[0032] As shown in FIG. 3 , the difference between the present embodiment and the first embodiment lies in the arrangement of the positive and negative electrodes of the solar cells.

Embodiment 3

[0034] As shown in Figure 4, the difference between this embodiment and Embodiment 1 is that a spring 9 is also provided in the hollow chamber, and rubber pads 10 are placed on both ends of the spring 9, and the upper end of the spring 9 is pressed against the solar cell. sheet 5, so that the solar battery sheet 5 is close to the lower surface of the top glass plate 1, and the lower end of the spring 9 is against the upper surface of the bottom glass plate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com