Preparation of supported nanometer nickel catalyst and application thereof

A catalyst and nano-nickel technology, applied in the field of preparation of new catalysts, can solve problems such as easy spontaneous combustion of framework nickel, environmental pollution, loss of price advantage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Using alumina as a carrier, take 20ml of PdCl2 solution with a Pd content of 0.002g / ml, add 5g of alumina carrier, stir and impregnate at room temperature for 4h, filter with suction, and dry at 120°C for 2h. The resulting 0.2% Pd / Al 2 o 3 Put the carrier into the nickel-phosphorus plating solution (preparation conditions: 150ml of water, 9.77g of potassium sodium tartrate, 4.47g of nickel sulfate, 4.52g of sodium hypophosphite, and adjust the Ph value to 12.5 with ammonia water), stir, and the carrier will gradually turn black until there are no bubbles Erupt, stop stirring, the nanometer-Ni / Al that the amount of gained nickel is 15% 2 o 3 -1 Catalyst is washed with water until neutral, washed with alcohol and stored in absolute ethanol.

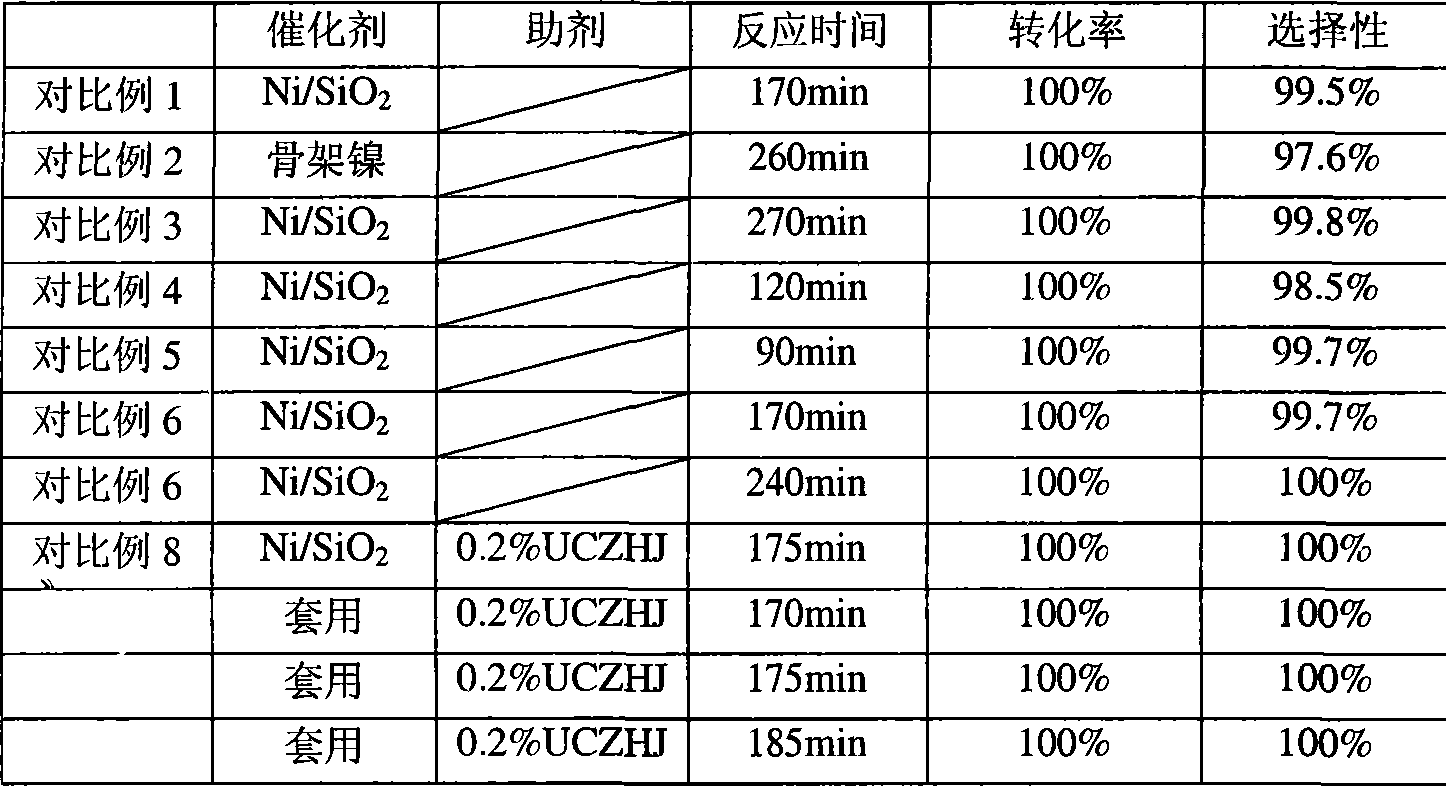

[0012] The catalyzer that obtains carries out hydrogenation reaction, and condition is as described in reaction process condition below, and corresponding reaction result is shown in Table 1

Embodiment 2

[0014] Using alumina as the carrier, take 20ml of nickel sulfate solution with a Ni content of 0.002g / ml, add 5g of alumina carrier, stir and impregnate at room temperature for 4h, filter with suction, and dry at 120°C for 2h. The resulting 0.2% Ni / Al 2 o 3 The carrier is beaten in 15ml of water, under the condition of stirring, with the concentration of 2mol / 1 KBH 4 Solution reduction (molar ratio KBH 4 : Ni=2:1), the obtained 0.5%Ni-B / Al 2 o 3 Put the precursor into the nickel-phosphorus plating solution, stir, and stop stirring until no bubbles emerge, and the resulting nano-Ni / Al 2 o 3 -2 The catalyst is washed with water to neutrality, and stored in absolute ethanol after alcohol washing. Corresponding reaction condition is with embodiment 1, and the results are shown in Table 1

Embodiment 3

[0016] The preparation conditions are the same as in Example 2, the pH value of the plating solution configured in Example 2 is reduced to 8, and the rest of the conditions are the same as in Example 2. Prepared Nano-Ni / Al 2 o 3 -3 Catalyst. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com