Magnetic toner

A toner and magnetic technology, which is applied in the field of toner, can solve the problems of difficult to obtain magnetic toner of polyester resin, etc., and achieve the effects of excellent dot reproducibility, excellent fixability, and excellent high-temperature stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0238] Specific examples include: lubricants such as fluorinated resins, zinc stearate or polyvinylidene fluoride, among which polyvinylidene fluoride is preferred; abrasives such as cerium oxide, silicon carbide or strontium titanate, among which strontium titanate is preferred; property-imparting agents such as titanium oxide or aluminum oxide, among which hydrophobic substances are preferred; antiblocking agents; conductivity-imparting agents such as carbon black, zinc oxide, antimony oxide or tin oxide; and development accelerators such as white and black fine particles, these materials can be used in small quantities.

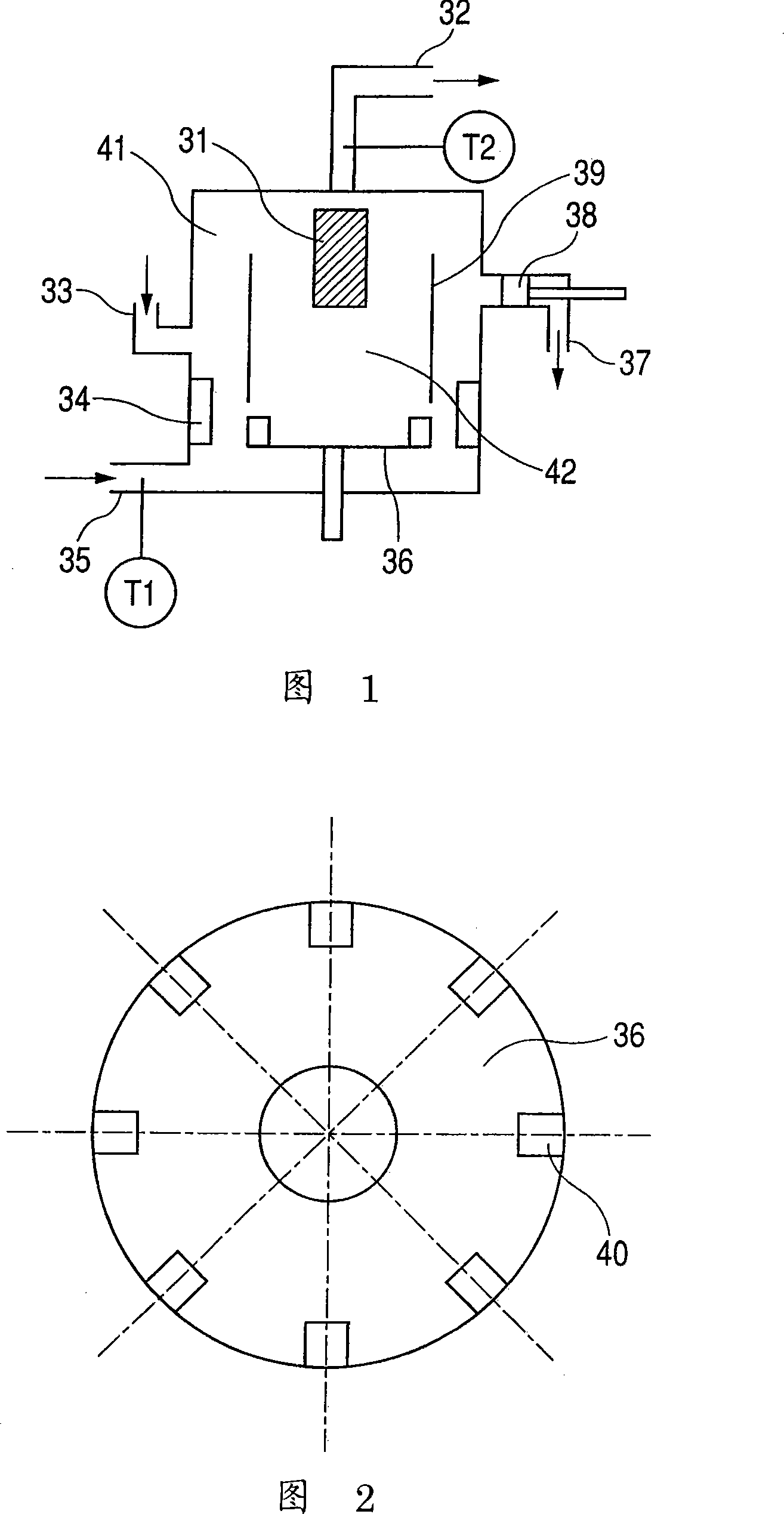

[0239] The magnetic toner of the present invention can be produced by an ordinary method for producing toner particles for developing an electrostatic charge image. As materials of the magnetic toner of the present invention, at least the above-mentioned binder resin and magnetic iron oxide are used, and other materials such as colorants, waxes, charge con...

Embodiment 1

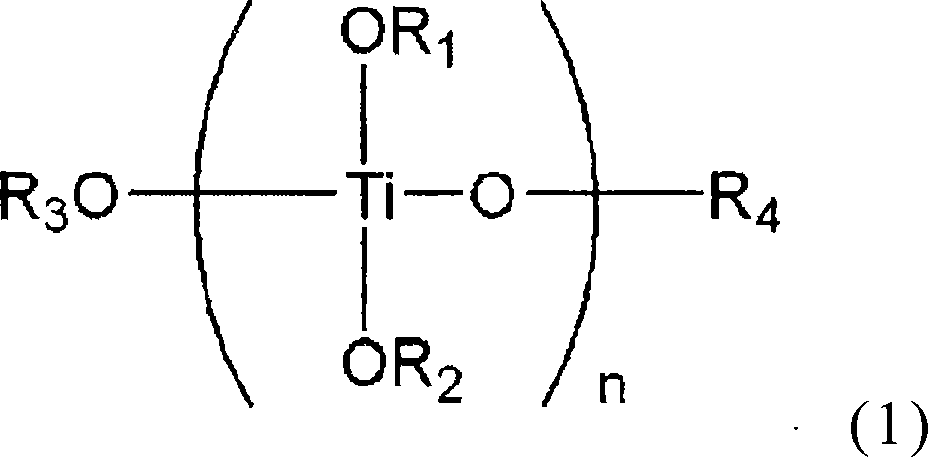

[0306] Dissolve 19.6 parts by weight of terephthalic acid in 100 parts by weight of pyridine, then add 80.4 parts by weight of tetra-n-butoxytitanium dropwise, and place the resulting mixture at 40°C for 2 hours under a nitrogen atmosphere to make the tetra-n-butoxytitanium Titanium oxide reacts with terephthalic acid. Then, pyridine and butanol formed by the reaction were distilled off under reduced pressure to produce aromatic carboxylate titanium compound 1 .

Embodiment 2

[0308] Except that 19.6 parts by weight of terephthalic acid was changed to 36.1 parts by weight of trimellitic anhydride, and 80.4 parts by weight of tetra-n-butoxytitanium was changed to 63.9 parts by weight, in the same manner as in Production Example 1 of the aromatic carboxylate titanium compound Implement the production process.

[0309] To produce aromatic carboxylate titanium compound 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com