Electrophotographic image forming method

An electrophotographic and image technology, which is applied in the direction of an electric recording process using a charge pattern, an electric recording process applying a charge pattern, an equipment for an electric recording process applying a charge pattern, etc. High hardness, scraper wear and other problems, to achieve the effect of stable image density, increased penetration force, and small scraper wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0229] There is no particular limitation on the preparation method of the coating liquid for forming a protective layer. A polymerizable monomer, an inorganic filler, and optionally used polymerization initiators and other components can be added to a dispersion medium, and stirred until dissolved or dispersed.

[0230] The protective layer can be formed by drying and curing the protective layer-forming coating liquid prepared by the above method after applying it on the photosensitive layer.

[0231] In the above-mentioned coating, drying, and curing processes, the reaction between polymerizable monomers, and in the case where the inorganic filler has a polymerizable group, the reaction between the polymerizable monomer and the inorganic filler, and the reaction between the inorganic filler The reaction and the like proceed, and a protective layer including a cured product of the composition for protective layer formation is formed.

[0232] The coating method of the coating ...

Embodiment

[0314] Hereinafter, although an Example is given and this invention is concretely demonstrated, this invention is not limited to these Examples. It should be noted that in the following examples, unless otherwise specified, operations were performed at room temperature (25° C.). In addition, unless otherwise specified, "%" and "part" mean "mass%" and "mass part", respectively.

[0315]

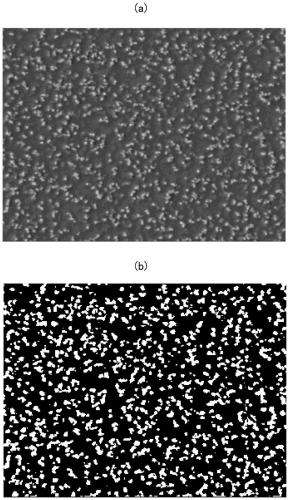

[0316] use Figure 5 The fabrication device shown in , fabricated on barium sulfate (BaSO 4 ) The surface of the core material (nucleus) is formed with tin oxide (SnO 2 ) of the coating layer (shell) of the composite particles. It should be noted that the composite particles are represented as "SnO 2 / BaSO 4 ".

[0317] Concretely, drop into pure water 3500cm in the mother liquor tank 41 3 , and then throw in 900 g of spherical barium sulfate core materials with an average primary particle diameter of 95 nm, and make it circulate 5 times. The flow velocity of the slurry that flows ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com