Re123 oxide superconductor and method for manufacturing same

A technology of RE123 and manufacturing method, which is applied in the field of RE123 oxide superconductors and its manufacturing, and can solve the problems of slow film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] Make the mixed raw material with a particle size of about 0.05 μm (the Er of 1-5 μm 2 BaO 4 Powder and Ba x -Cu y -O z Department of raw materials [BaCuO 2 +CuO] to get ErBa 2 Cu 3 o 7-δ The mixing ratio is mixed, and then Ag 2 (O added 2% by mass of Ag, pulverized for 10 hours) adhered to the Ag substrate, and heated at 900°C for 3 hours in an Ar atmosphere containing 1% oxygen to form ErBa 2 Cu 3 o 7-δ superconductor.

[0188] By pairing the resulting ErBa 2 Cu 3 o 7-δ X-ray diffraction intensity measurement of superconductors and scanning electron microscope (SEM) observation of the crystal surface confirmed that ErBa with excellent crystal orientation was stably formed on the entire surface of the Ag substrate at low temperature. 2 Cu 3 o 7-δ superconductor.

[0189] This indicates that crystal orientation at low temperature can be sufficiently performed by reducing the particle diameter of the mixed raw material to less than 1 μm.

[0190] In addi...

Embodiment 2

[0192] The same mixed raw material used in Example 1 was uniaxially molded into a 6 mm pellet (pellet) shape, packed into an Ag tube with an inner diameter of 6 mm and an outer diameter of 10 mm, and then processed to reduce the cross section, and processed into a width of 3 mm, Ribbon wire with a thickness of 1mm.

[0193] Then, heat-treat the strip-shaped wire rod in the atmosphere at 920°C, then cut a 100mm-long wire sample from the wire rod, slowly cool it in an oxygen stream from 700°C to 400°C for 200 hours, and introduce Oxygen.

[0194] The critical current characteristic of the wire sample was measured by the 4-terminal method, and the critical current density was 880A / cm 2 .

Embodiment 3

[0196] Make the mixed raw material with a particle size of about 0.1 μm (the Er of 1-5 μm 2 BaO 4 Powder and Ba x -Cu y -O z Department of raw materials [BaCuO 2 +CuO] to get ErBa 2 Cu 3 o 7-δ Mixed at a mixing ratio of 4% by mass of Ag2O, then pulverized for 4 hours) filled into an Ag tube with an inner diameter of 6 mm, an outer diameter of 12 mm, and a length of 20 cm, and the reduced section was processed into a plate thickness of 0.3 mm to make a flat plate shaped Ag armored wire material.

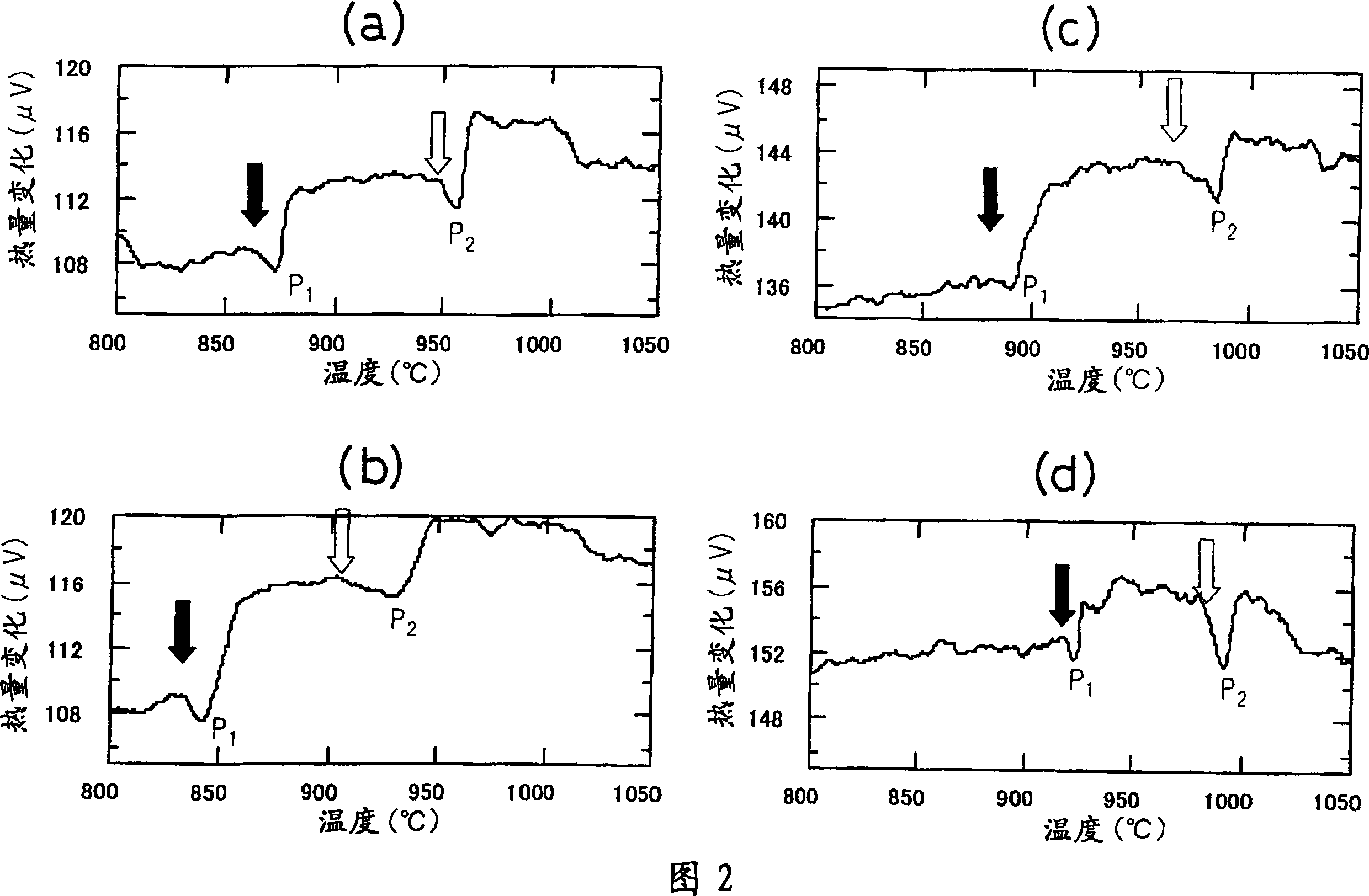

[0197] The above materials were heated at 925°C for 8 minutes in an Ar atmosphere containing 1% oxygen, followed by heating at (a) 875°C, (b) 850°C, (c) 825°C, and (d) 800°C Treated for 2 hours, ErBa was formed 2 Cu 3 o 7-δ superconductor.

[0198] By pairing the resulting ErBa 2 Cu 3 o 7-δ X-ray diffraction intensity measurement and scanning electron microscope (SEM) observation of the crystal surface confirmed that: after heat treatment at 925°C for 8 minutes, followe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com