Ink-jet printing high luster casting-coating photographic paper

An inkjet printing, high-gloss technology, applied in coatings, pigmented coatings, etc., can solve the problems of unsuitable pigment ink printing, reduced pore openness in coatings, etc., and achieve reliable printing performance and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

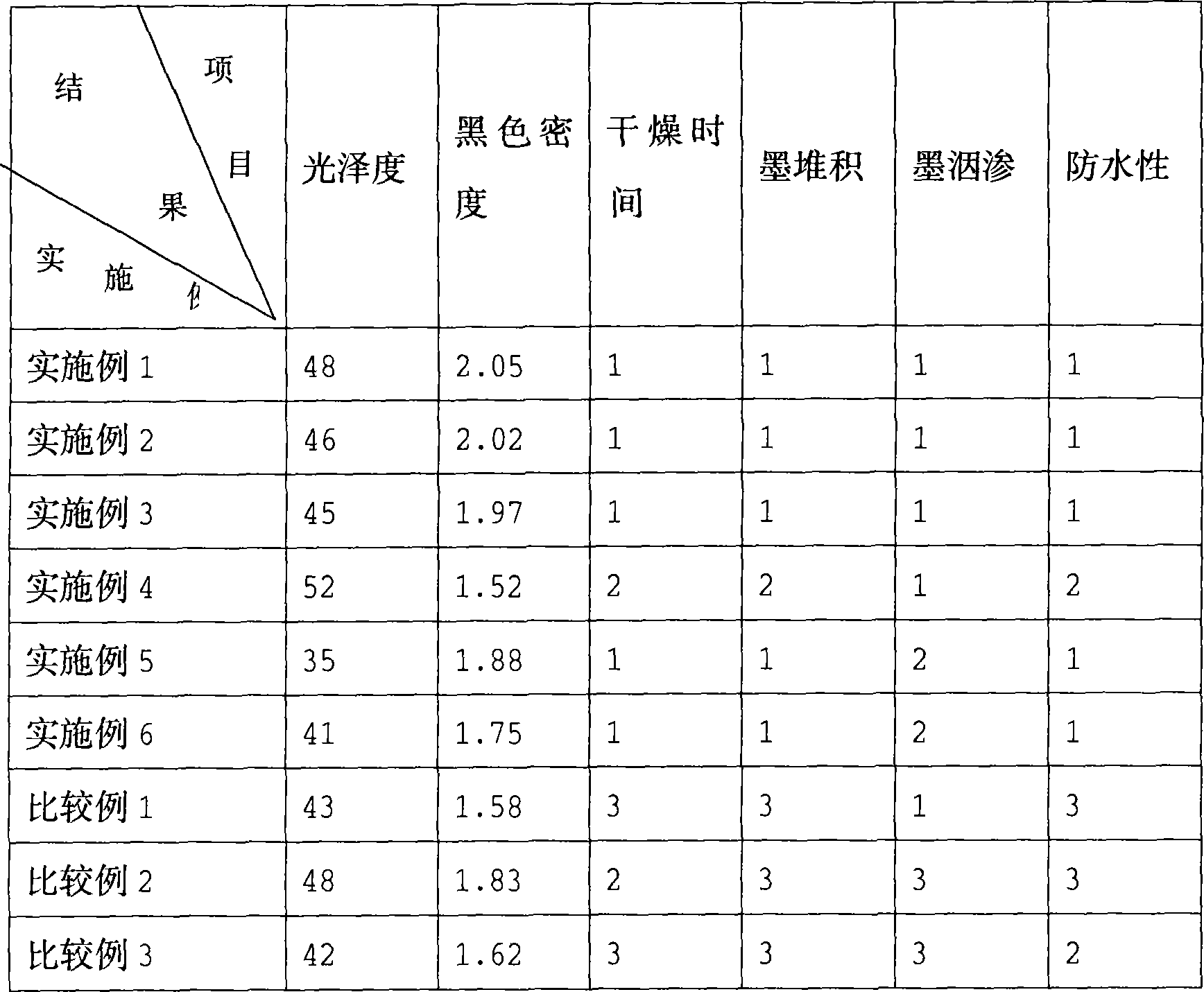

Examples

Embodiment 1

[0036] The lower coating solution of cast-coated photo paper consists of 100 parts of silicon dioxide (SD-640, Beijing Aerospace Saide Powder Material Technology Co., Ltd.), 22 parts of polyvinyl alcohol, 28 parts of polyethylene / vinyl acetate, 8 parts of quaternary ammonium Salt polymer, 3 parts of polypolyol amine, made into a water-based coating solution with a concentration of 20%, coated on photographic base paper by doctor blade coating, and dried to form the lower layer of cast-coated photographic paper.

[0037] Top layer coating liquid formula:

[0038] Aluminum oxide 90 parts

[0039] 5 parts polyvinyl alcohol

[0040] Styrene / maleic anhydride / acrylic acid copolymer emulsion 5 parts

[0041] Polydimethyldiallyl ammonium chloride 3 parts

[0042] BYK-022 0.3 copies

[0043] QT-1 0.2 parts

[0044] 580 parts of deionized water.

[0045] In a container equipped with a stirring device, add 580 parts of water, 90 parts of aluminum oxide and 3 parts of polydimethyldi...

Embodiment 2

[0048] The coating formulation and process of the lower layer of cast-coated photographic paper are the same as in Example 1.

[0049] Top layer coating liquid formula:

[0050] Aluminum oxide 95 parts

[0051] 3 parts polyvinyl alcohol

[0052] Styrene / maleic anhydride copolymer emulsion 5 parts

[0053] Polydimethyldiallyl ammonium chloride 4 parts

[0054] 0.2 parts of isopropanol

[0055] QT-1 0.2 parts

[0056] 600 parts of deionized water.

[0057] In a container equipped with a stirring device, add 600 parts of water, 95 parts of alumina and 4 parts of polydimethyldiallylammonium chloride, stir and disperse to obtain an alumina dispersion with an average particle size of 0.2 μm, and then Add 5 parts of styrene / maleic anhydride copolymer emulsion, stir and mix evenly, add 3 parts of polyvinyl alcohol (10% aqueous solution), 0.2 parts of defoamer BYK-022, 0.2 parts of stripping agent QT-1, and mix well The upper layer coating liquid was obtained.

[0058] Apply th...

Embodiment 3

[0060] The coating formulation and process of the lower layer of cast-coated photographic paper are the same as in Example 1.

[0061] Top layer coating liquid formula:

[0062] Silicon oxide 94 parts

[0063] 4 parts polyvinyl alcohol

[0064] Acrylate / maleic anhydride copolymer emulsion 15 parts

[0065] Polytrimethacrylamide Chloride 3 parts

[0066] 0.8 parts of n-butanol

[0067] QT-1 0.3 parts

[0068] 658 parts of deionized water

[0069] In a container equipped with a stirring device, add 658 parts of water, 94 parts of silicon oxide and 3 parts of polytrimethacrylamide chloride, stir and disperse to obtain a silicon oxide dispersion with an average particle size of 0.25 μm, and then add 15 1 part of acrylate / maleic anhydride copolymer emulsion, stir and mix evenly, add 3 parts of polyvinyl alcohol (10% aqueous solution), 1 part of defoamer n-butanol, 0.2 part of stripping agent QT-1, mix evenly to obtain the upper layer Coating solution.

[0070] Apply the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com