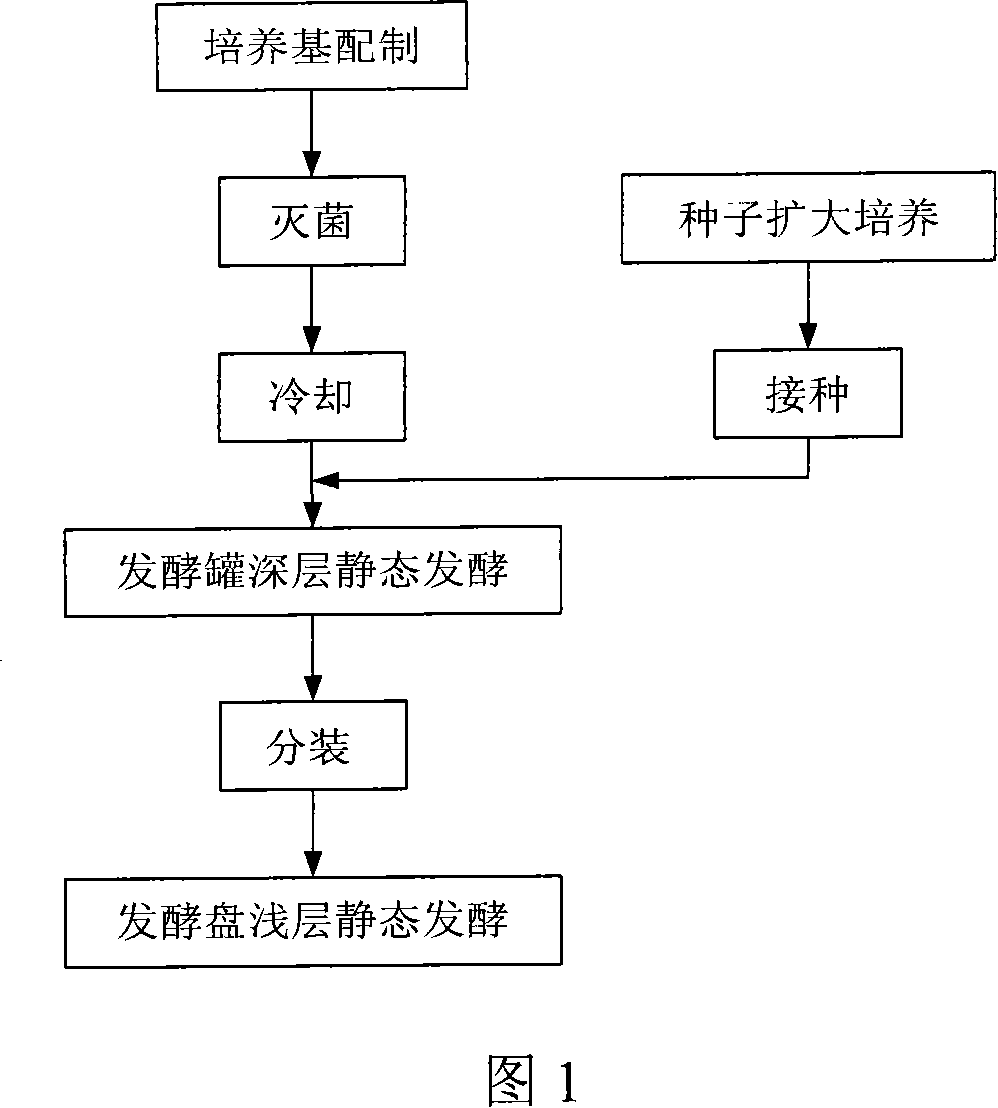

Method for producing Nata de Coco by deep layer and superficial layer static state couple fermentation

A static fermentation, shallow technology, applied in the biological field, can solve the problems of long fermentation cycle, etc., achieve the effect of improving utilization rate, low energy consumption, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Strain: Acetobacter Xylimum 1.1812 (purchased from Institute of Microbiology, Chinese Academy of Sciences)

[0023] (1) Expanded cultivation of seeds

[0024] Medium preparation: 2g sucrose, 0.4g yeast extract, NH 4 Cl 0.4g, MgSO 4 ·7H 2 O 0.02g, CaCl 2 0.02g, NaAC 0.01g, FeSO 4 0.5 mg, 20 mL of coconut water (fresh coconuts from Wenchang, Hainan, obtained by breaking the shell), dilute to 100 mL with tap water, adjust the pH to 5.0, put into a 500 mL triangular bottle, wrap the mouth of the bottle with 8 layers of gauze, and sterilize at 121°C for 20 minutes. After cooling to 28-32°C, add a loop of activated slant strains (inoculated with a conventional inoculation loop), place on a shaking incubator at a constant temperature of 30°C, and shake at 150r / min for 12 hours to obtain a seed solution.

[0025] (2) deep static fermentation

[0026] Medium preparation: 3000g sucrose, 600g yeast extract, NH 4 Cl 600g, MgSO 4 ·7H 2 O 30g, CaCl 2 30g, NaAC 15g, FeSO ...

Embodiment 2

[0031] Strain: Acetobacter Xylimum 1.1812

[0032] (1) Expanded cultivation of seeds

[0033] Medium preparation: 5g sucrose, 0.3g yeast extract, NH 4 Cl 0.8g, MgSO 4 ·7H 2 O 0.04g, CaCl 2 0.04g, NaAC 0.02g, FeSO 41.0 mg, 80 mL of coconut water (fresh coconuts from Wenchang, Hainan, obtained by breaking the shell), dilute to 200 mL with tap water, adjust the pH to 5.5, put into a 1000 mL triangle bottle, wrap the mouth of the bottle with 8 layers of gauze, and sterilize at 121°C for 20 minutes. After cooling to 28-32°C, insert a ring of activated slant strains (inoculated with a conventional inoculation loop), place on a shaking incubator at a constant temperature of 30°C, and shake at 150r / min for 16 hours to obtain a seed solution.

[0034] (2) deep static fermentation

[0035] Medium preparation: 20kg sucrose, 1.2kg yeast extract, NH 4 Cl 3.2kg, MgSO 4 ·7H 2 O 160g, CaCl 2 160g, NaAC 80g, FeSO 4 4g, 320L of coconut water (fresh coconuts from Wenchang, Hainan, ...

Embodiment 3

[0039] Strain: Acetobacter Xylimum 1.1812

[0040] (1) Expanded cultivation of seeds

[0041] Seed cultivation adopts the expanded cultivation process of "incline → triangular flask → seed tank", as follows:

[0042] (a) Medium preparation: NH 4 Cl 0.4g, MgSO 4 ·7H 2 O 0.02g, CaCl 2 0.02g, 100mL coconut water (fresh coconuts from Wenchang, Hainan, obtained by breaking the shell), adjust the pH to 5.5, put it into a 500mL triangular bottle, wrap the mouth of the bottle with 8 layers of gauze, sterilize at 121°C for 20min, cool to 28-32°C Insert a ring of activated slant strains (inoculated with a conventional inoculation loop), place in a shaking incubator at a constant temperature of 30°C and shake at 150 r / min for 12 hours to obtain a seed solution.

[0043] (b) Medium preparation: NH 4 Cl 30g, MgSO 4 ·7H 2 O 1.5g, CaCl 2 1.5g, 7.5L of coconut water (fresh coconuts from Wenchang, Hainan, obtained by breaking the shell), adjust the pH to 5.0, put into a 10L fermente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com