Special-purpose slag adjusting agent for vanadium-titanium-iron-water-magnesium desulfurization

A technology of vanadium-titanium-iron and slag-adjusting agent is applied in the field of iron and steel metallurgy, which can solve the problems of serious sulfur return in steelmaking furnaces, and achieve the effects of reducing iron loss, improving removal rate and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Grind 70 parts of lime, 3 parts of fluorite, 9 parts of manganese ore, 4 parts of expanded graphite, 7 parts of calcium carbide, 11 parts of glass powder, and 3 parts of MgO, and then use a Raymond mill to further grind until the particle size of each raw material is 80% or less. 1mm and the maximum particle size is not more than 10mm, and finally mixed to obtain the special slagging agent for desulfurization of vanadium-titanium-magnesium hot metal of the present invention.

[0016] The special slagging agent for desulfurization of vanadium-titanium-magnesium hot metal prepared above contains 64.8% of CaO and 64.8% of CaF 2 2.55%, containing MnO4.3%, containing expanded graphite 3.8%, containing SiO 2 8.1%, with CaC 2 4.7% with MgO 3.2% with Al 2 o 3 (Manganese ore contains Al 2 o 3 ) 3.2%.

Embodiment 2

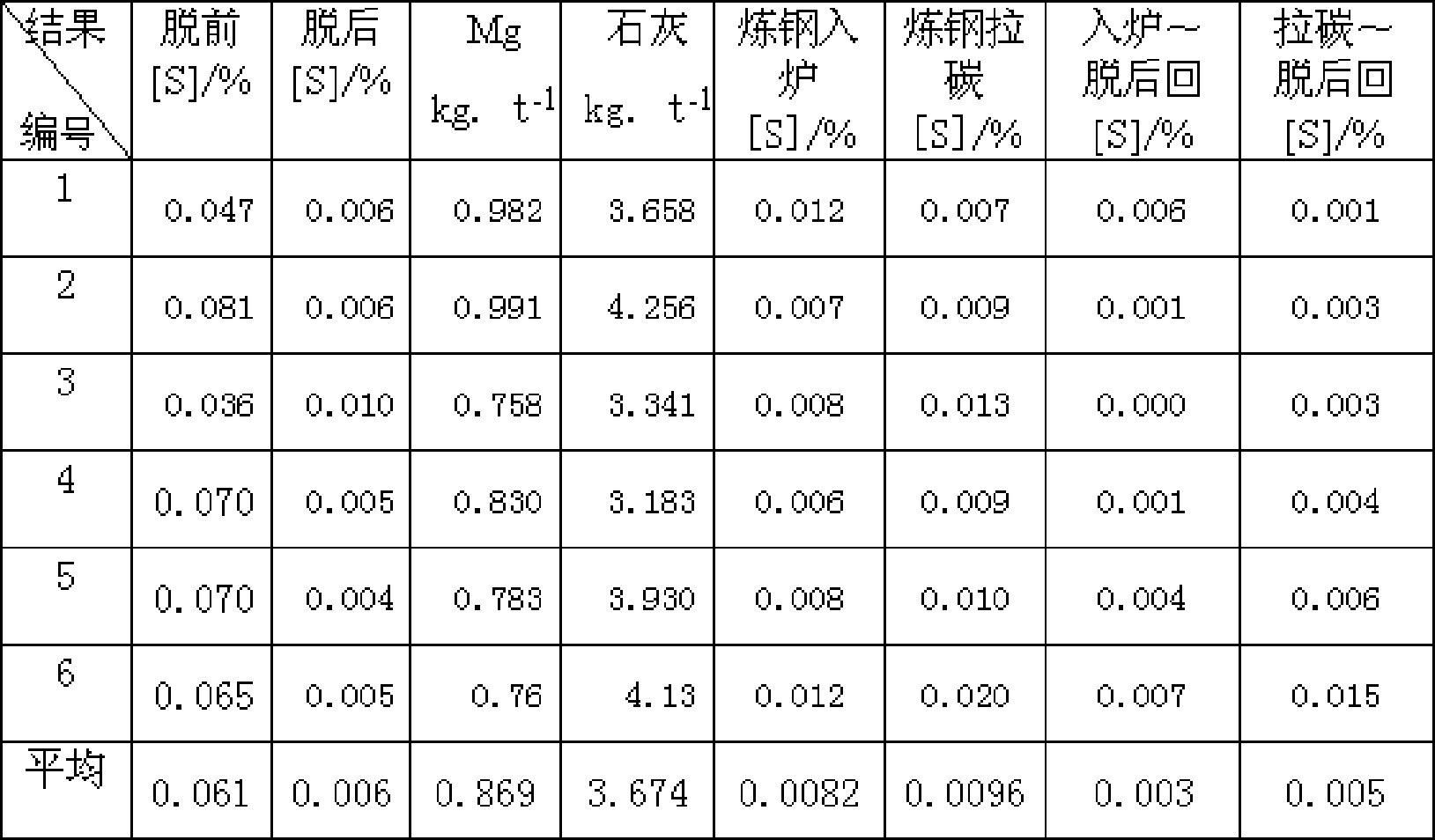

[0018] The slagging agent prepared in Example 1 was tested in Panzhihua Iron and Steel Vanadium Extraction Steelmaking Plant. The amount of slagging agent added was 200kg / furnace, and each furnace of molten iron was about 130 tons. Each furnace was numbered 1, 2, 3, 4, and 5. The test results are shown in Table 2, in which Mg and lime are desulfurizers.

[0019] Steelmaking into the furnace [S] / %: initial sulfur content of molten iron entering the steelmaking furnace.

[0020] Steel-making drawn carbon [S] / %: Sulfur content in steel-making drawn carbon sampling.

[0021] Furnace-return after desulfurization [S] / %: The difference between the initial sulfur content of the steelmaking furnace and the sulfur content after desulfurization. The smaller the value, the cleaner the desulfurization slag is removed, and the better the sulfur return control effect is.

[0022] Decarburization ~ return after desulfurization [S] / %: The difference between the sulfur content of the steelmaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com