Sensitivity predicating coating material containing phenyl fluorine sensitive matter

A technology of phenylfluorone and coating materials, which is applied in the directions of luminescent materials, analytical materials, and optical testing for flaws/defects, etc. It can solve the problems of on-site detection of corrosion damage, in-situ detection of corrosion parts, quantitative evaluation of corrosion speed, error , It is difficult to monitor the corrosion rate in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

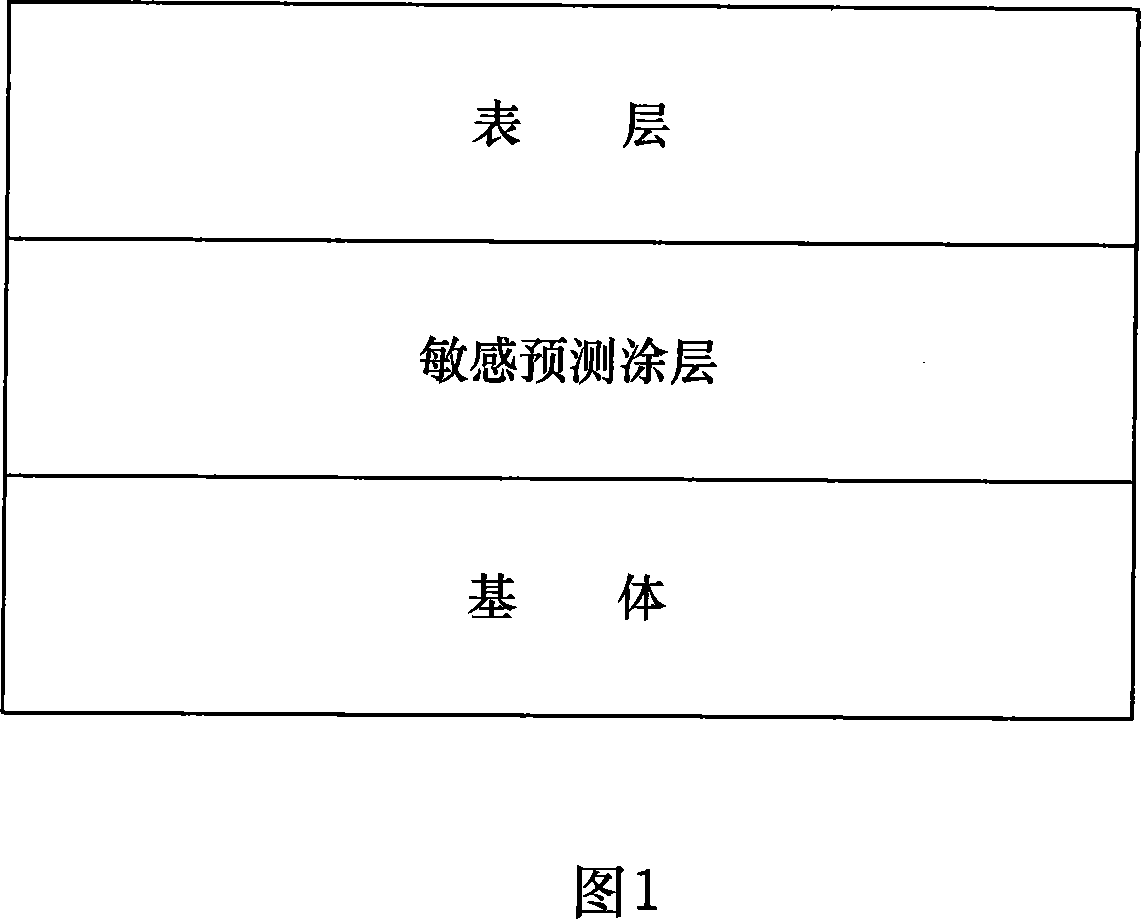

[0008] The predictive coating material of the application of the present invention uses the fluorescent corrosion sensing intelligent coating as a corrosion monitoring means, uses the fluorescent compound as the corrosion sensing material, and utilizes it under different oxidation and reduction states, different pH values, and with specific The characteristic of the fluorescence property changing after the metal ion recombination is combined with the coating to be used in corrosion monitoring. This technology has high sensitivity for in-situ monitoring of aluminum alloy corrosion, and can detect the presence of aluminum ions in the ppm range, which provides the possibility to monitor the occurrence and development of early corrosion, evaluate the corrosion state in real time, and obtain important corrosion environment information.

[0009] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com