Photocatalytic material photocatalytic activity characterization method and device

A photocatalytic material and photocatalytic activity technology, applied in the field of material performance characterization, can solve the problems of power consumption, complex equipment and high instrument price, and achieve the effects of low daily maintenance cost, simple reaction process and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

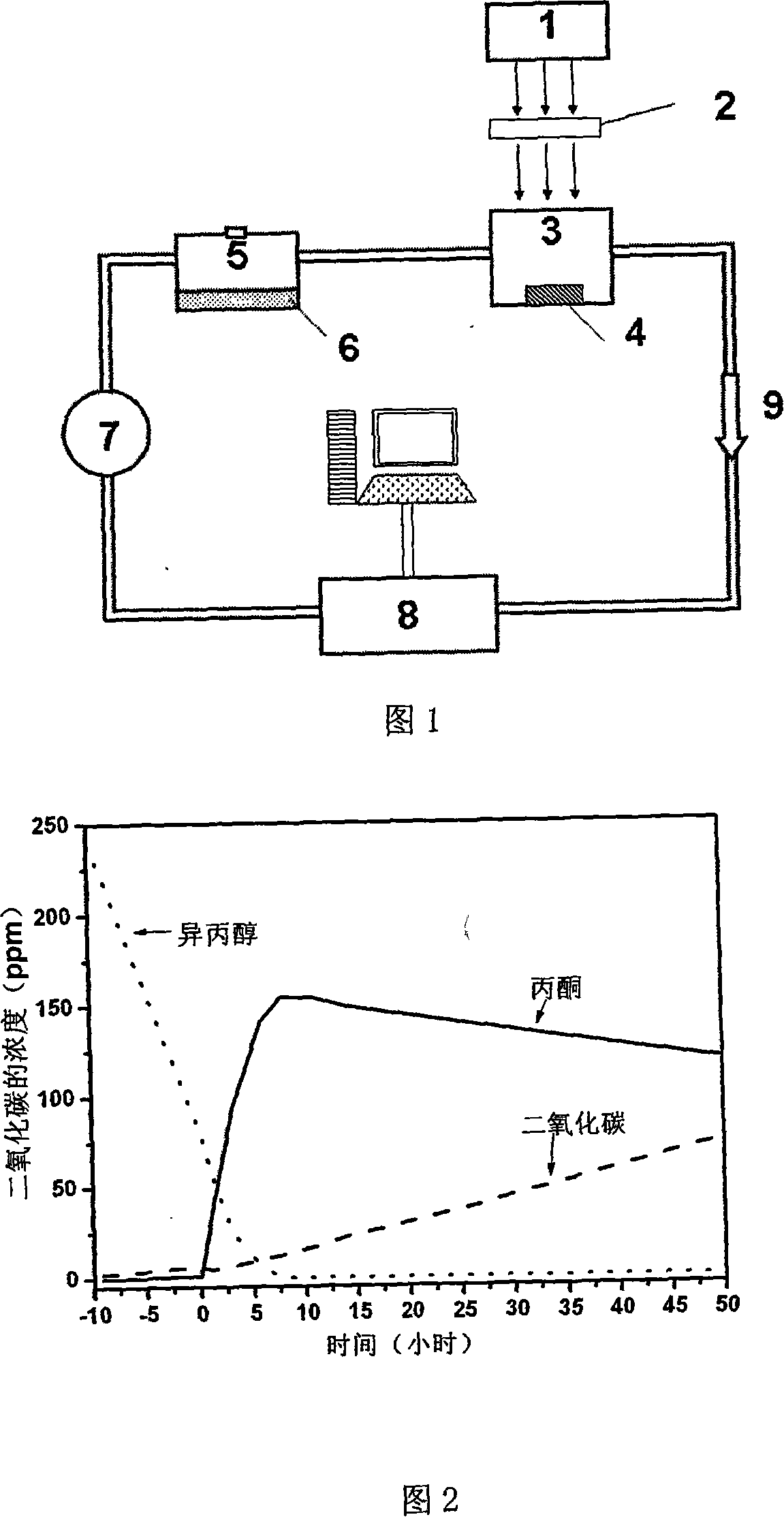

[0035] Implementation case 1: Photocatalytic reaction of acetone and carbon dioxide from photodegradation of isopropanol.

[0036] First, the powder sample is spread in a circular glass tank with a diameter of 2 cm, and the circular glass tank containing the sample is placed in the reactor, and the film sample can be directly put into it. Cover the quartz plate and securely seal. Open the quick connector in the closed circuit system, connect the air filter to the air inlet valve, turn on the gas circulation pump, and use clean air to clean the reactor, pipeline, and the gas chamber in the infrared gas analyzer to remove adsorbed pollutants , This process can also choose to use carbon dioxide-free air distribution gas for purging. Connect the quick connector and inject 10ul isopropanol into the sample vaporization chamber with the injection needle. Start the circulation pump to circulate for 30 minutes to completely vaporize the injected isopropanol. Turn on the infrared gas analyz...

Embodiment example 2

[0037] Implementation case 2: The photocatalytic reaction of the photodegradation of acetaldehyde to carbon dioxide.

[0038]First, spread the powder sample in a pre-made circular glass tank with a diameter of 2 cm, and place the circular glass tank containing the sample in the reactor, and the film sample can be directly put in. Cover the quartz plate and securely seal. Open the quick connector in the closed circuit system, connect the air filter to the air inlet valve, turn on the gas circulation pump, and use clean air to clean the reactor, pipeline, and the gas chamber in the infrared gas analyzer to remove adsorbed pollutants , This process can also choose to use carbon dioxide-free air distribution gas for purging. Connect the quick connector and inject 10ul of 40% acetaldehyde solution into the sample vaporization chamber with a sample needle. Start the circulating pump to circulate for 60 minutes to completely vaporize the injected acetaldehyde. Turn on the infrared gas an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com