Adulation method for MOS transistor body area

A technology of MOS transistor and body region, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as reduced carrier mobility, increased parasitic capacitance and leakage current, and leakage parasitic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

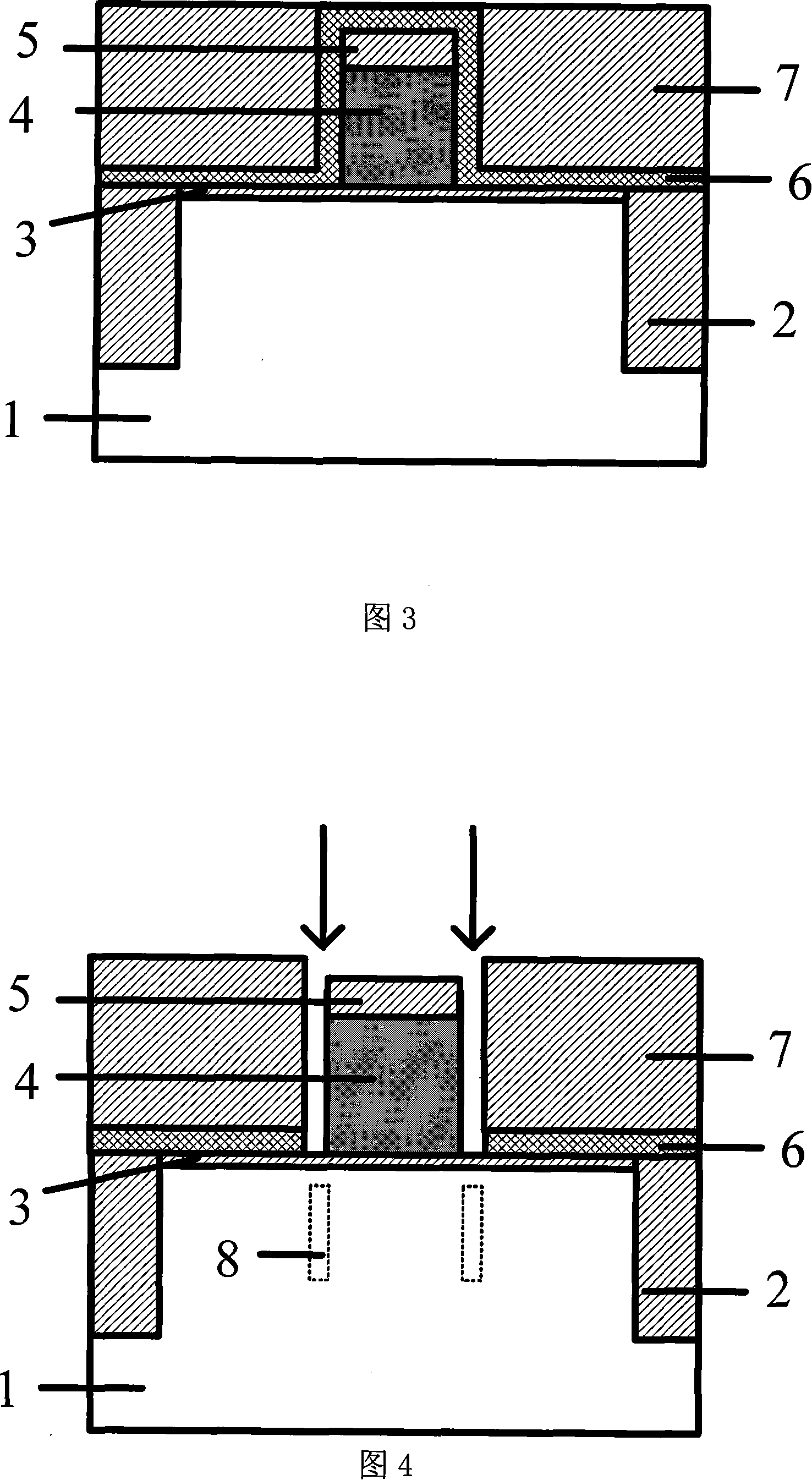

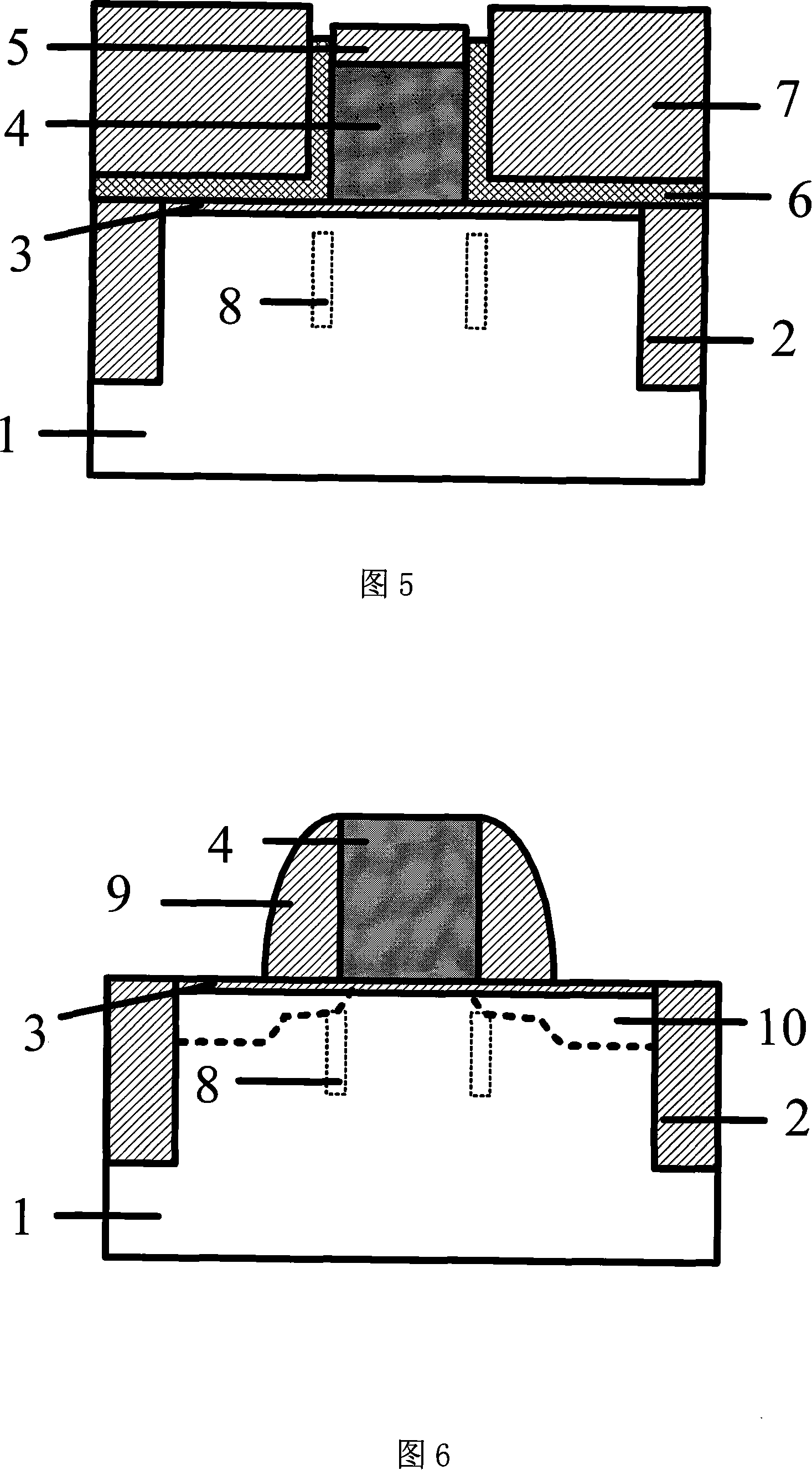

[0040] The preferred embodiment of the present invention is described in more detail below with reference to the accompanying drawings of the present invention.

[0041] (1) The substrate is a bulk silicon wafer

[0042] A specific example of the fabrication method for preparing an integrated silicon MOS transistor is shown in Figures 1 to 6, including the following steps:

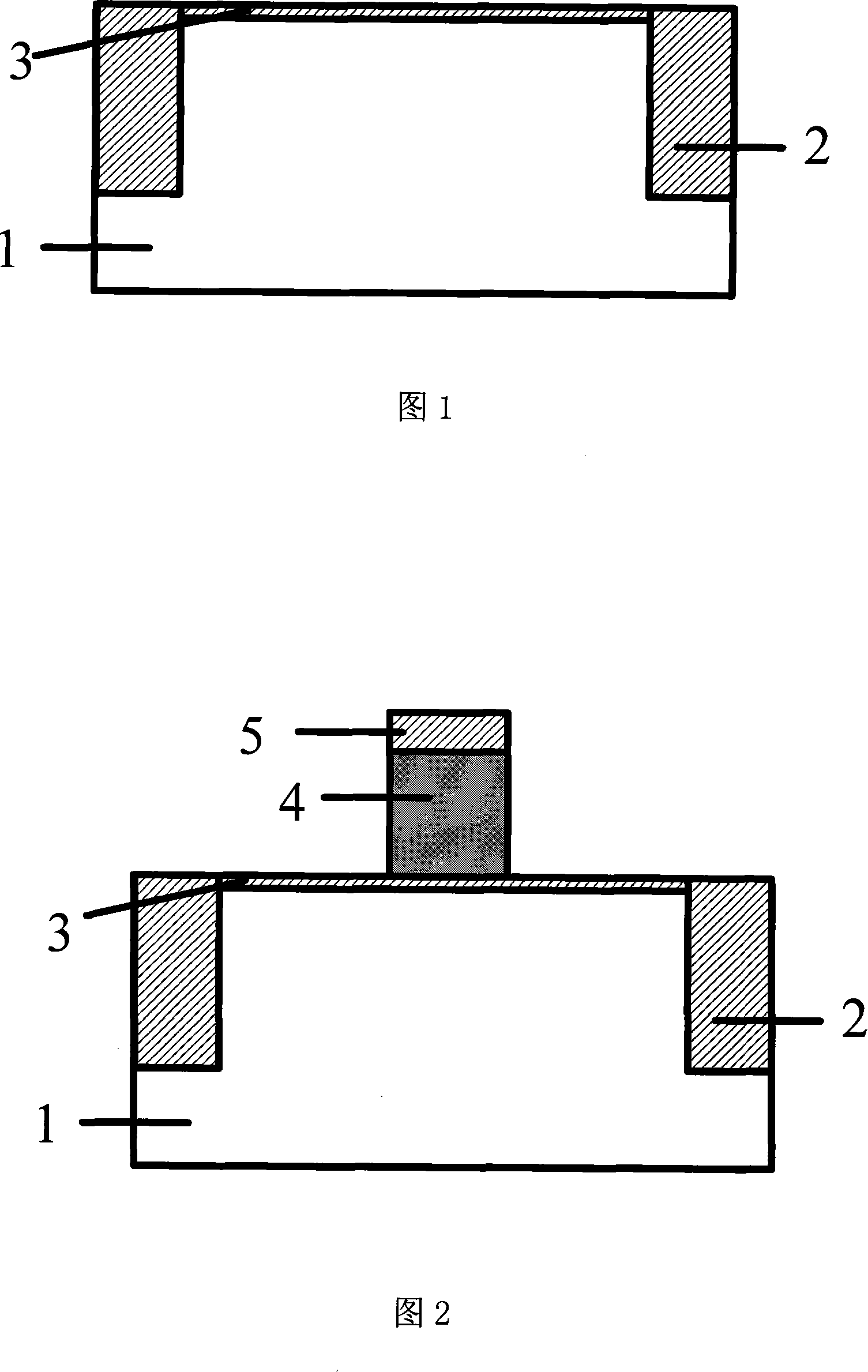

[0043] 1) As shown in Figure 1, the crystal orientation of the single crystal silicon substrate used is (100), and for n-type MOS transistors, the body region 1 is initially lightly doped with p-type. For p-type MOS transistors, body region 1 is initially lightly doped with n-type. The active region isolation layer 2 is fabricated by using conventional CMOS shallow trench isolation technology. Next, a gate dielectric layer 3 is grown. The gate dielectric layer 3 is silicon dioxide with a thickness of 0.5-3 nm. The gate dielectric can also be formed by one of the following methods: conventional thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com