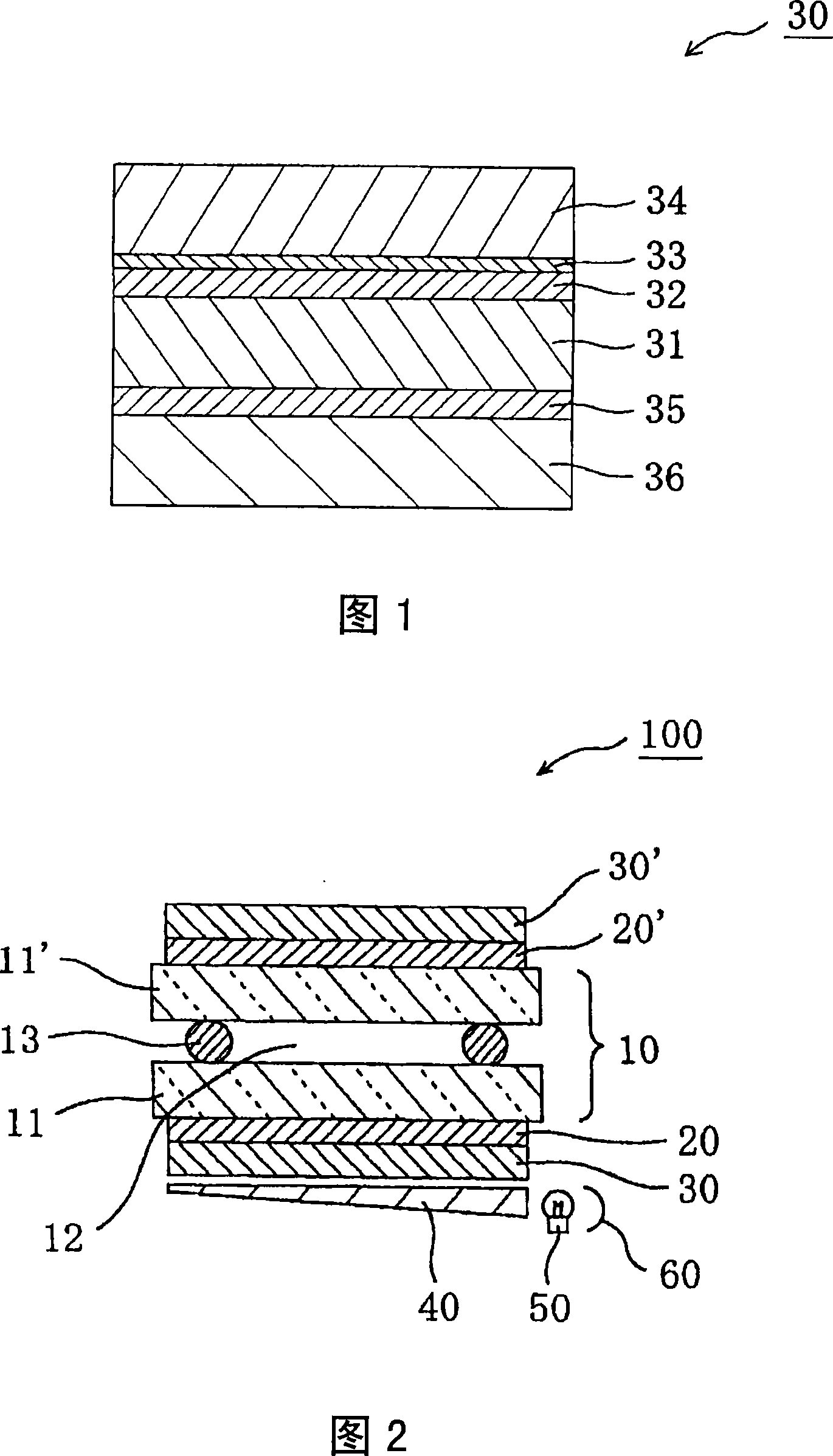

Polarizer protection film, polarizing plate, and image display unit

A technology for protective films and polarizers, applied in the direction of polarizing elements, instruments, layered products, etc., can solve the problems of resin coloring yellowing, reduce, reduce heat resistance, etc., achieve excellent heat resistance, excellent ultraviolet absorption ability, Effect of Excellent Optical Transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] (polarizer)

[0160] A polyvinyl alcohol film having a thickness of 80 μm was dyed in a 5% by weight (weight ratio: iodine / potassium iodide=1 / 10) iodine aqueous solution. Next, it is immersed in an aqueous solution containing 3% by weight of boric acid and 2% by weight of potassium iodide, and then extended to 5.5 times in an aqueous solution containing 4% by weight of boric acid and 3% by weight of potassium iodide, and then immersed in an aqueous solution of 5% by weight of potassium iodide. middle. Then, drying was performed in an oven at 40° C. for 3 minutes to obtain a polarizer with a thickness of 30 μm.

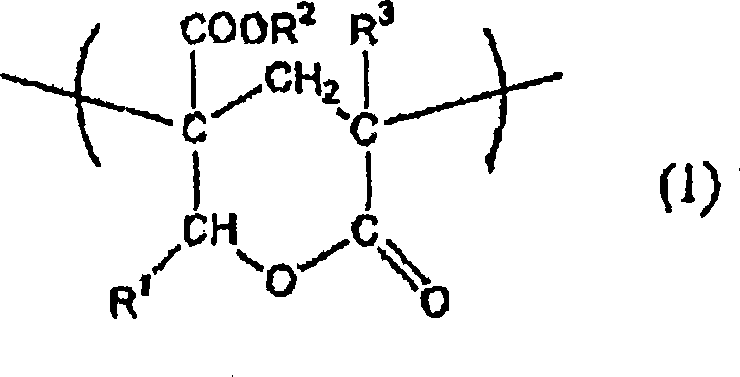

[0161] (Manufacture of lactone-containing cycloacrylic resin)

[0162] 8000g of methyl methacrylate (MMA), 2000g of 2-(hydroxymethyl)methyl acrylate (MHMA) and 10000g of toluene were charged into a 30L reactor equipped with a stirring device, a temperature sensor, a cooling pipe, and a nitrogen introduction pipe In this regard, nitrogen gas was passed while h...

Embodiment 2

[0184] In the preparation of the polarizer protective film of Example 1, in addition to using 1 part of TINUVIN 1577 (manufactured by Ciba Specialty Chemicals) and 0.5 part of ADEKASTAB LA-31 (manufactured by Asahi Denka Industries) instead of 1 part of TINUVIN1577 (manufactured by Ciba Specialty Chemicals) 1 part and 1 part of ADEKASTAB LA-31 (manufactured by Soden Chemical Industry Co., Ltd.), the others were carried out in the same manner as in Example 1.

[0185] Table 1 shows the evaluation results of the obtained polarizer protective film and the evaluation results of the appearance of the obtained polarizer. In addition, in the obtained polarizing plate, the adhesiveness of the polarizer protective film and the polarizer was favorable, the polarizer and the polarizer protective film were integrated, and peeling did not generate|occur|produce.

Embodiment 3

[0187] In the preparation of the polarizer protective film of Example 1, in addition to using 0.5 part of TINUVIN1577 (manufactured by Ciba Specialty Chemicals) and 1 part of ADEKASTAB LA-31 (manufactured by Asahi Denka Industries) instead of 1 part of TINUVIN1577 (manufactured by Ciba Specialty Chemicals) Except for 1 part of ADEKASTAB LA-31 (manufactured by Asahi Denka Kogyo Co., Ltd.), the same procedure as in Example 1 was carried out.

[0188] Table 1 shows the evaluation results of the obtained polarizer protective film and the evaluation results of the appearance of the obtained polarizer. In addition, in the obtained polarizing plate, the adhesiveness of the polarizer protective film and the polarizer was favorable, the polarizer and the polarizer protective film were integrated, and peeling did not generate|occur|produce.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com