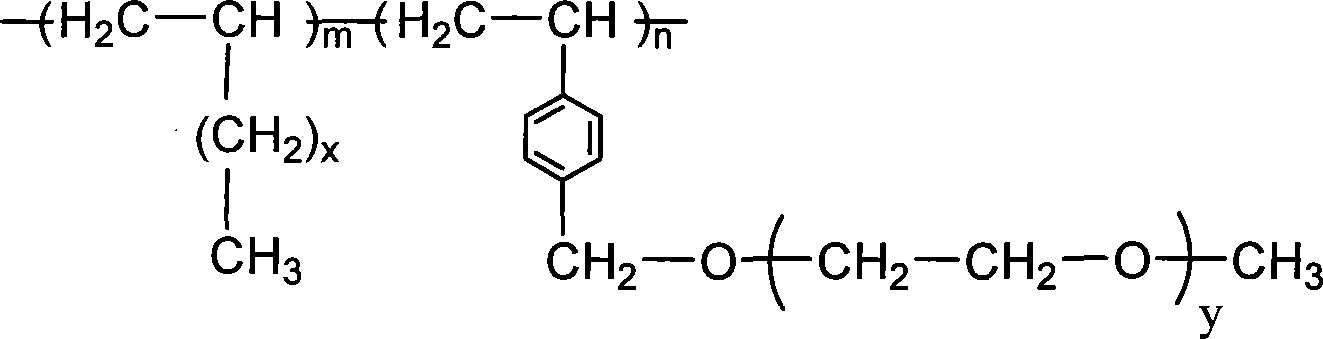

Strong-hydrophobicity long chain alpha-olefin amphiphilic graft copolymer

A technology of olefin copolymers and graft copolymers, which is applied in the field of strong lipophilic long-chain α-olefin amphiphilic graft copolymers and its preparation, and can solve problems such as difficult solubility in non-polar or polar solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

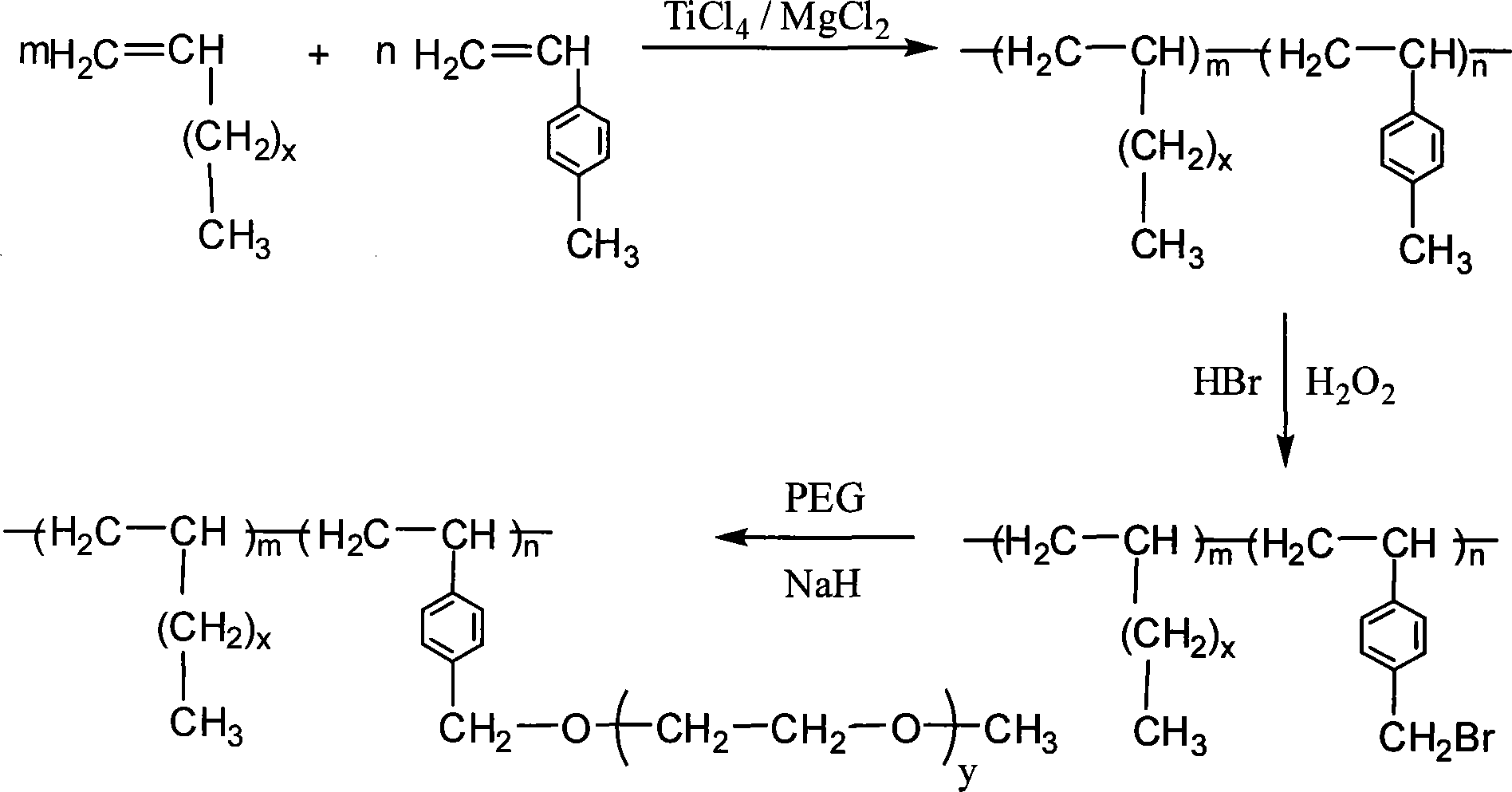

Method used

Image

Examples

Embodiment 1

[0015] Step 1) thoroughly remove oxygen and water in the reactor, add successively the heptane solution of 40 milliliters of n-heptane, 8.71 milliliters of 1-hexene, 1.29 milliliters of p-methylstyrene, 0.833 milliliters of triisobutylaluminum (concentration 2mol / L), the heptane solution (concentration 0.5mol / L) of 0.133 milliliters of diphenyldimethoxysilane, the heptane solution (concentration 0.05mol / L) of 0.785 milliliters of diethylzinc, 0.044 gram main catalyst, Polymerization was carried out at 50°C for 2 hours to obtain 4.28 g of a p-methylstyrene-1-hexene copolymer. The content of p-methylstyrene structural unit in this copolymer is 11.57% (mole percentage composition), and molecular weight is 5.5 * 10 4 g / mol.

[0016] Step 2) 0.35 grams of the above-mentioned copolymers are dissolved in 15 milliliters of carbon tetrachloride, then the solution is put into an ice-water bath, slowly add 0.2 milliliters of hydrobromic acid (concentration 40%), then slowly add 0.1 mil...

Embodiment 2

[0019] Step 1) thoroughly remove oxygen and water in the reactor, add successively the heptane solution of 40 milliliters of n-heptane, 4.57 milliliters of 1-dodecene, 5.43 milliliters of p-methylstyrene, 0.675 milliliters of triisobutylaluminum (concentration 2mol / L), 0.11 milliliters of diphenyldimethoxysilane heptane solution (concentration 0.5mol / L), 2.47 milliliters of diethylzinc heptane solution (concentration 0.05mol / L), 0.04 gram main catalyst, Polymerization was carried out at 50°C for 2 hours to obtain 3.48 g of p-methylstyrene-1-dodecene copolymer. The content of p-methylstyrene structural unit in this copolymer is 58.5% (mole percentage composition), and molecular weight is 3.3 * 10 4 g / mol.

[0020] Step 2) 1.44 grams of the above copolymers are dissolved in 70 milliliters of carbon tetrachloride, then the solution is put into an ice-water bath, slowly add 2 milliliters of hydrobromic acid (concentration 40%), then slowly add 1 milliliter of 30% Hydrogen peroxi...

Embodiment 3

[0023] Step 1) thoroughly remove oxygen and water in the reactor, add successively the heptane solution of 40 milliliters of n-heptane, 8.71 milliliters of 1-dodecene, 1.29 milliliters of p-methylstyrene, 0.833 milliliters of triisobutylaluminum (concentration 2mol / L), 0.133 milliliters of diphenyldimethoxysilane heptane solution (concentration 0.5mol / L), 0.785 milliliters of diethylzinc heptane solution (concentration 0.05mol / L), 0.042 gram main catalyst, Polymerization was carried out at 50°C for 2 hours to obtain 3.88 g of p-methylstyrene-1-dodecene copolymer. The content of p-methylstyrene structural unit in this copolymer is 14.66% (mole percentage composition), and molecular weight is 5.49 * 10 4 g / mol.

[0024] Step 2) 1.2 grams of the above-mentioned copolymers are dissolved in 60 milliliters of carbon tetrachloride, then the solution is put into an ice-water bath, slowly add 1.5 milliliters of hydrobromic acid (concentration 40%), then slowly add 0.8 milliliters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com