Scanning electron microscope electron back scattering diffraction in-situ stretching device and measuring method

A technology of electron backscattering and in-situ stretching, applied in measurement devices, material analysis using measurement secondary emissions, instruments, etc., can solve problems such as insufficiency, and achieve easy operation, reliable performance parameters, and easy interpretation and discovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

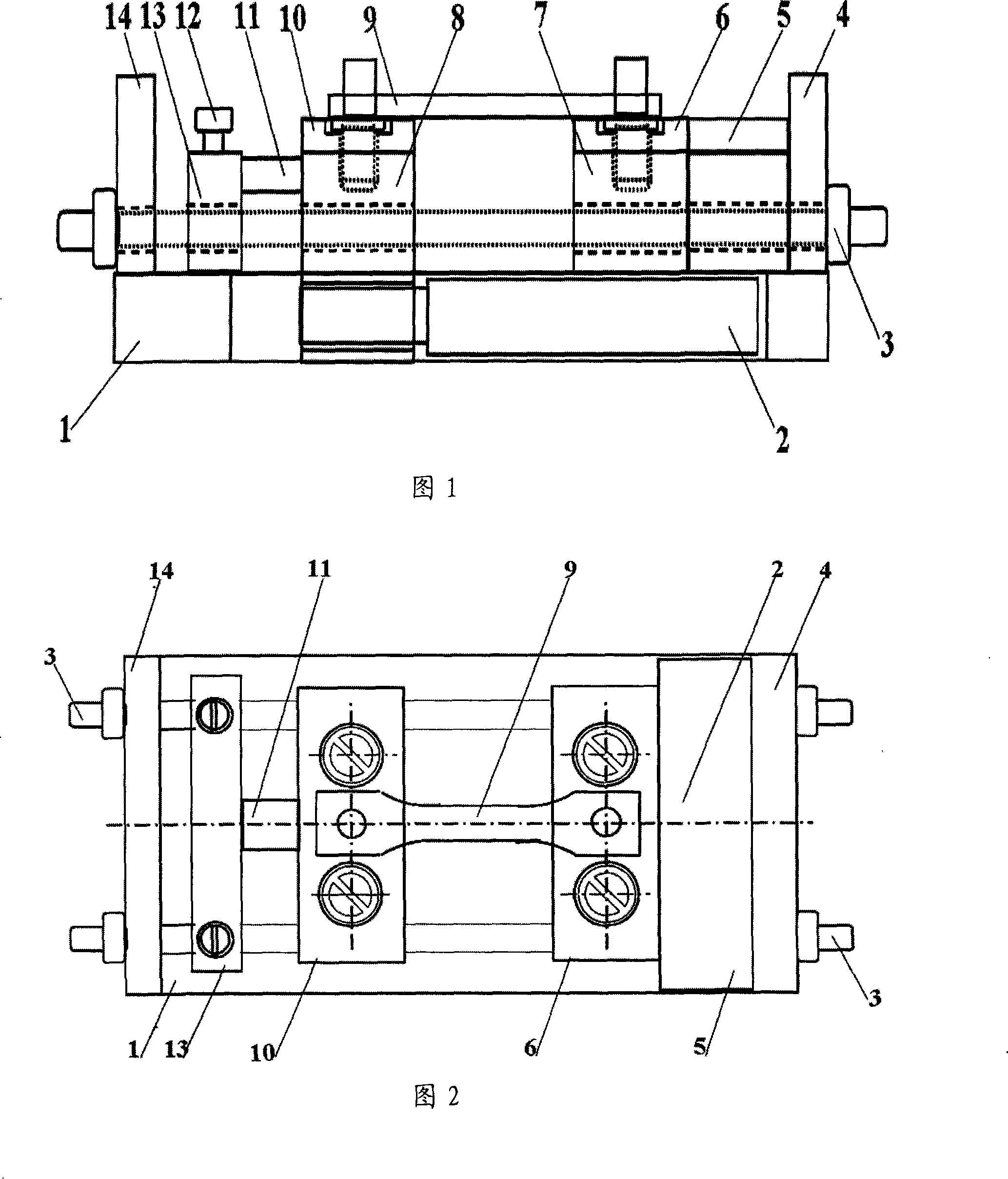

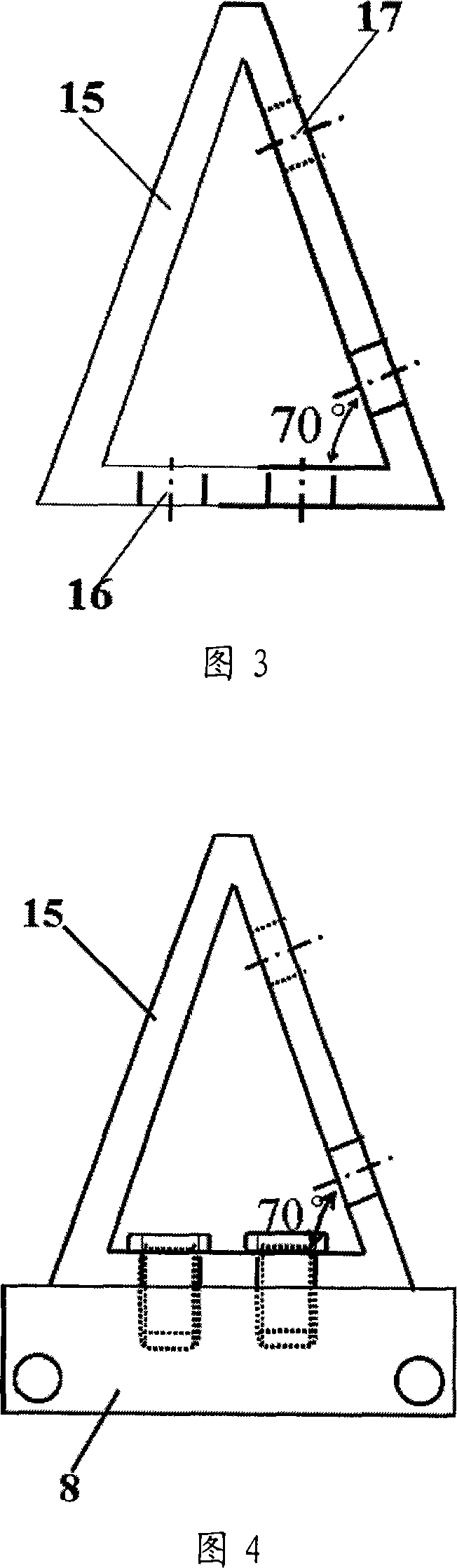

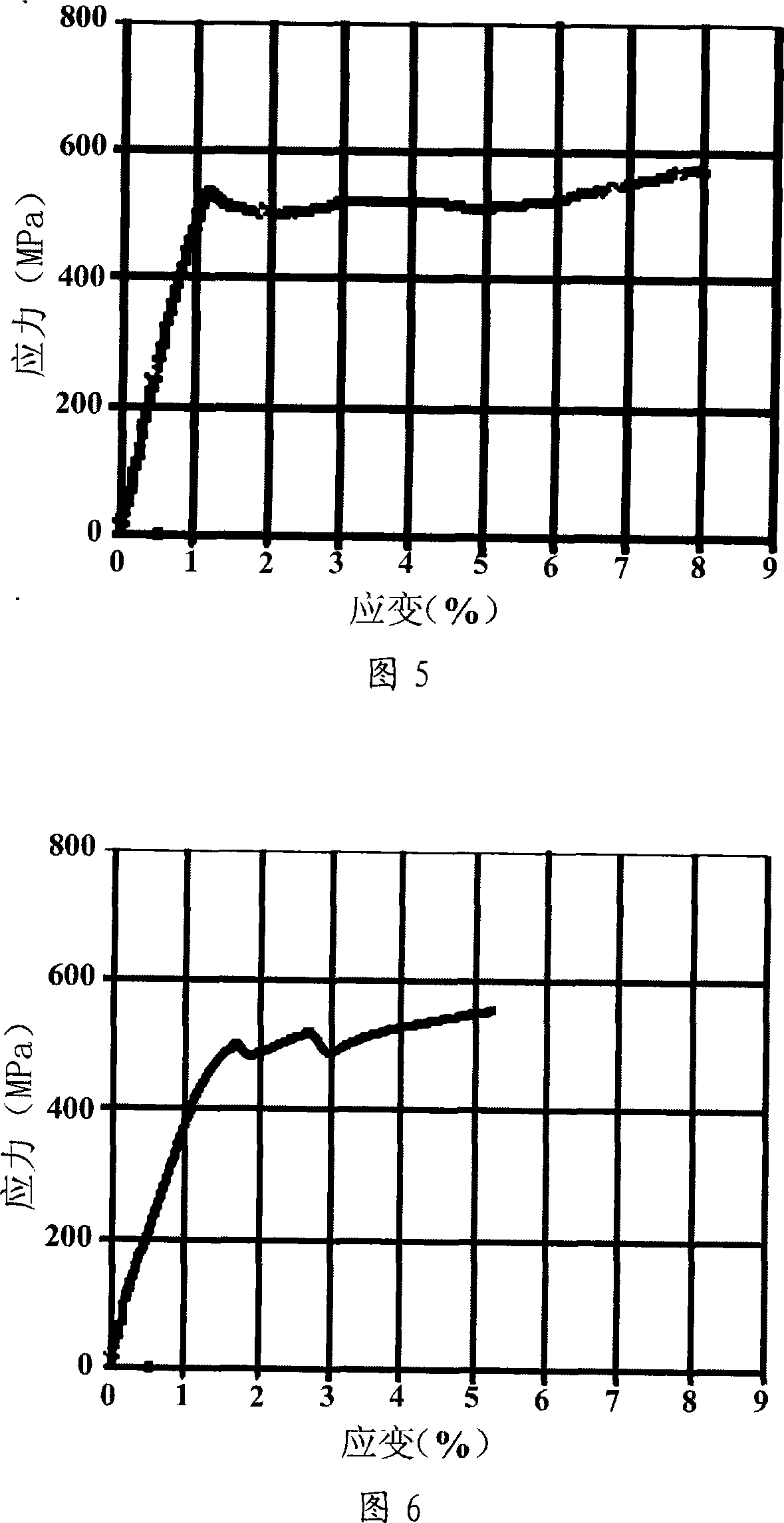

[0032]The scanning electron microscope electron backscattering diffraction in-situ stretching device is designed according to the FEI Quanta 200 environmental scanning electron microscope and the JEOL JSM 6500F field emission scanning electron microscope. The length, width and height of the device are 150mm×120mm×30mm, and the system uses a linear motor Drive, maximum loading load 500N, load accuracy 1%, piezoresistive stress sensor, maximum measurement load 5000N, accuracy 0.1N, linear displacement sensor, maximum linear displacement range 10mm, displacement accuracy 0.1μm, the device can be easily installed In the scanning electron microscope sample chamber. In the experiment, in the JEOL JSM 6500F field emission scanning electron microscope, the microscopic deformation process and the microscopic crack propagation process of the NiTi memory alloy were tested in the in-situ scanning electron microscopic imaging mode, and the NiTi memory alloy was obtained at the same time. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com