Direct methanol fuel battery anode catalyst and method for producing the same

A methanol fuel cell and catalyst technology, applied in the direction of catalyst activation/preparation, battery electrodes, chemical instruments and methods, etc., can solve the problems of reducing battery coulombic efficiency and voltage efficiency, cumbersome operation, catalyst poisoning, etc., and achieve easy control and process Simple, low-cost preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]Dissolve chloroplatinic acid and sodium tungstate in 2mol / L sulfuric acid at a molar ratio of 1:40, freshly make a uniform light yellow sol I and freshly prepare chloroplatinic acid with the same molar concentration as the light yellow sol and dissolve in 2mol / L sulfuric acid solution II. The glassy carbon electrode should be pretreated before electrodepositing the catalyst, using 5# metallographic sandpaper and 0.5μm Al 2 o 3 The polishing powder is polished, rinsed with double distilled water, then immersed in double distilled water and cleaned with ultrasonic waves, at 0.5mol / L H 2 SO 4 40 cyclic voltammetry scanning activation in the solution neutralization range of -0.2V ~ 0.9V, the scanning speed is 50mVs -1 .

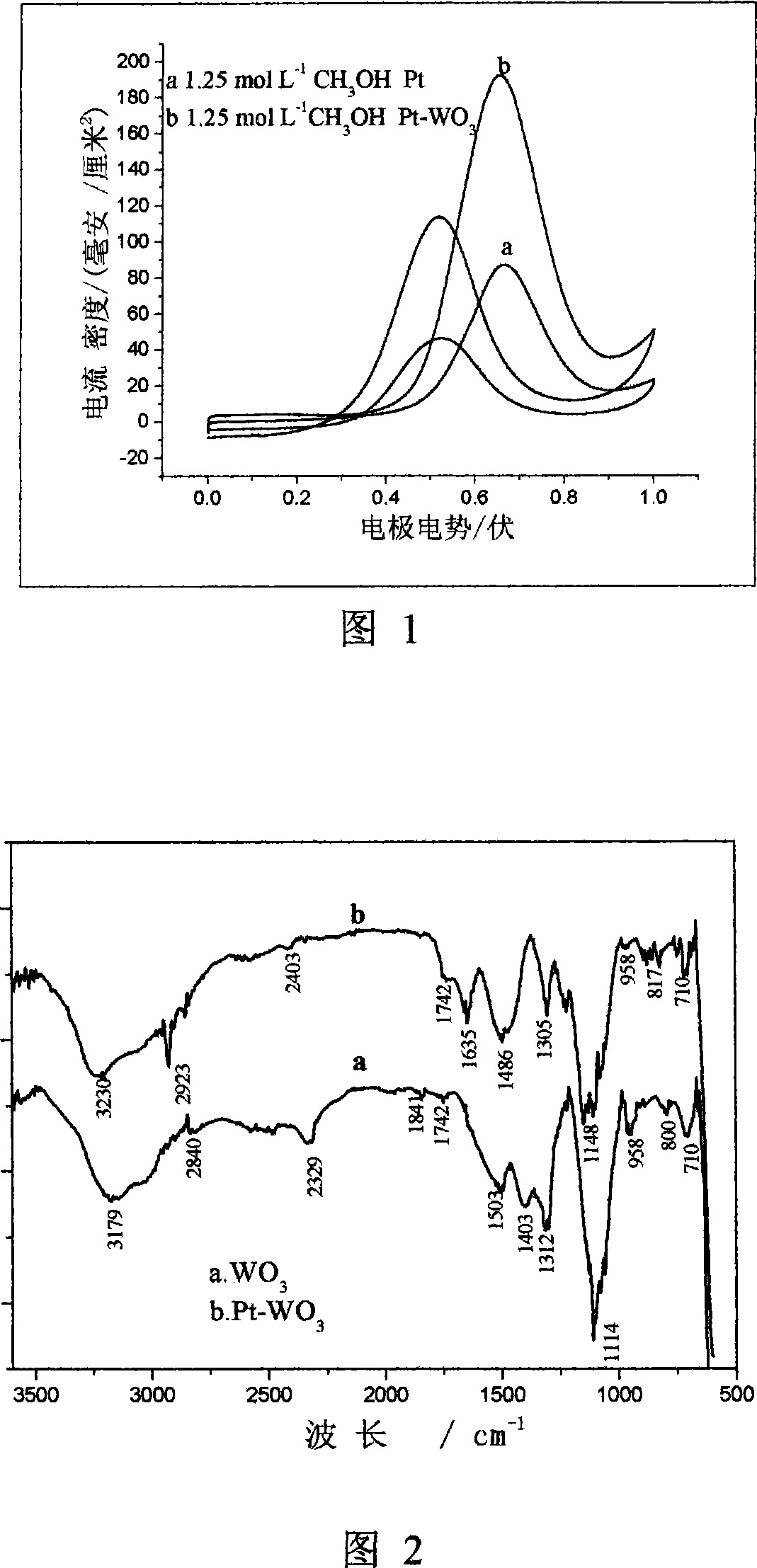

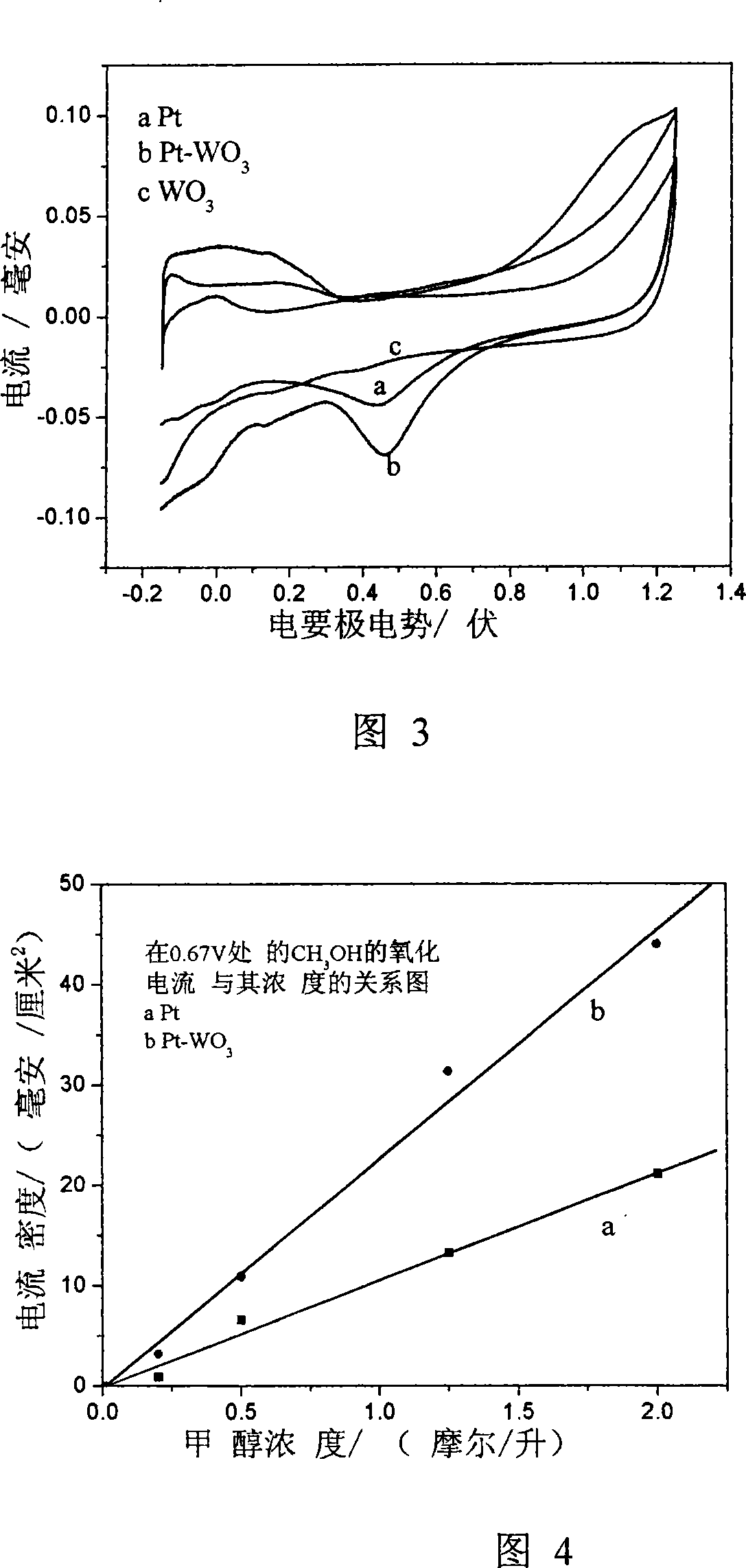

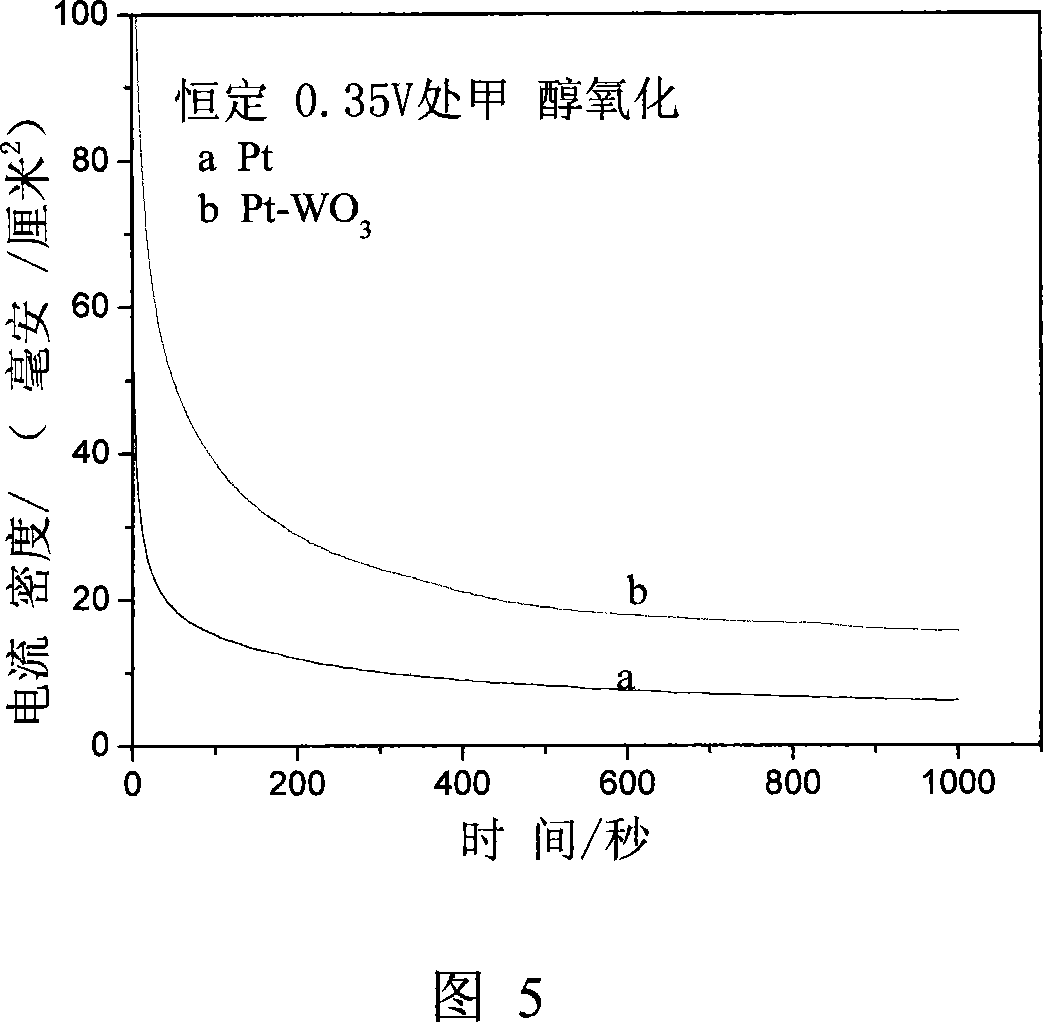

[0031] Then place the pretreated glassy carbon electrode in the above-mentioned sol I and chloroplatinic acid sulfuric acid solution II respectively, and electrodeposit at a constant -0.1V for 2000s to obtain a composite catalyst Pt-WO evenly dispersed ...

Embodiment 2

[0036] This embodiment is the same as Embodiment 1 except for the following features: electrodeposition at a constant -0.2V for 1000s, using carbon nanotubes instead of glassy carbon electrodes.

Embodiment 3

[0038] This embodiment is the same as Embodiment 1 except for the following features: constant 0.1V electrodeposition for 3000s, using activated carbon instead of glassy carbon electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com