Multi-reaction-area combination type reactor

A technology with multiple reaction zones and reactors, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of low ethylene propylene yield and low selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

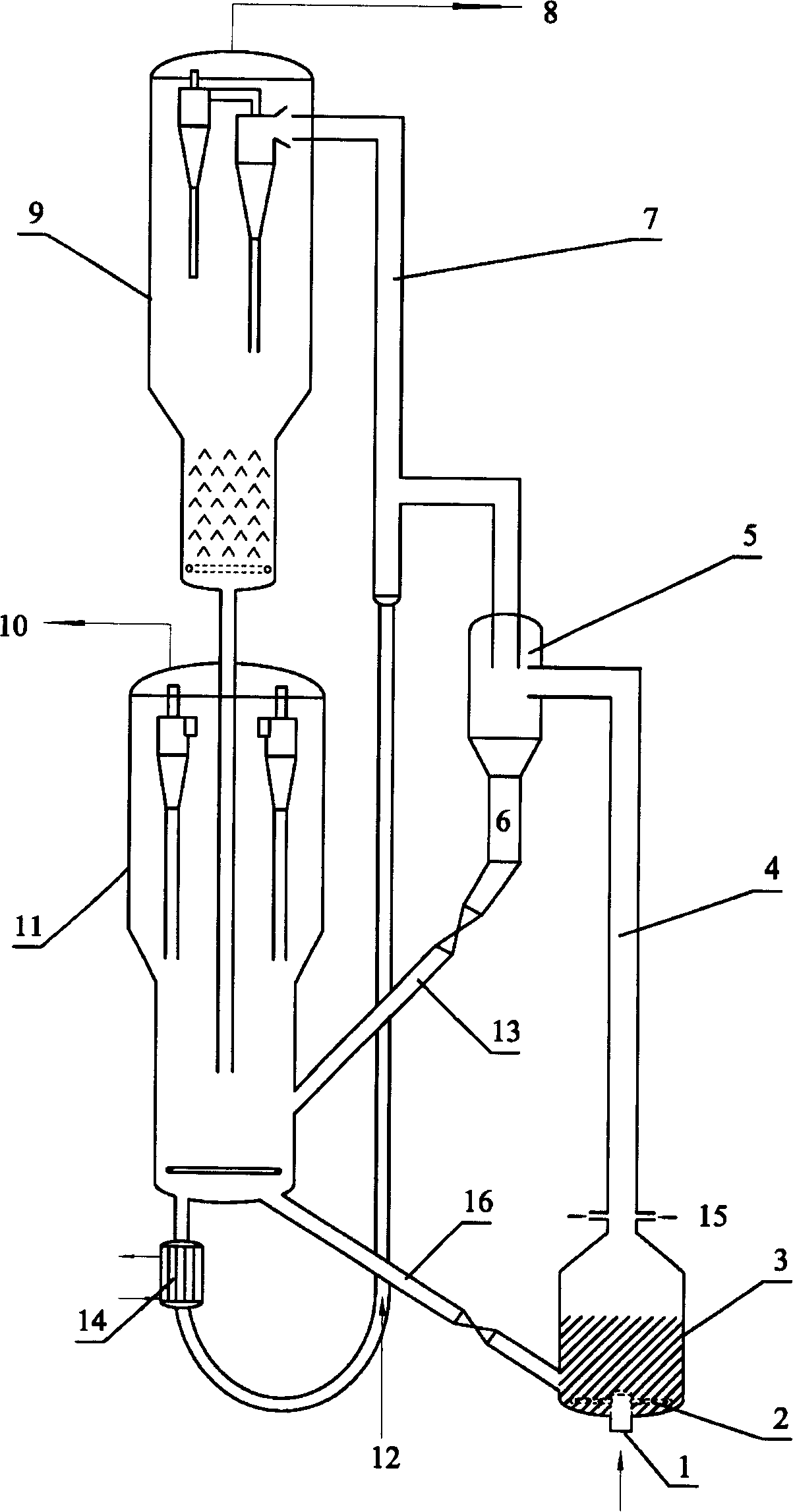

[0021] use figure 1The multi-reaction zone combined reactor, wherein the vertical distance between the raw material inlet B15 and the bottom of the first riser reactor 4 is 1 / 20 of the height of the first riser reactor 4 . The inner diameter of the first riser reactor 4 is 1 / 4 of the inner diameter of the fluidized bed reactor 3 , and the height of the first riser reactor 4 is 5 times the height of the fluidized bed reactor 3 . The height of the first riser reactor 4 is 0.8 times the height of the second riser reactor. The vertical height of the connecting port between the regeneration inclined pipe 16 and the fluidized bed reactor 3 from the bottom of the fluidized bed reactor 3 is 1 / 10 of the vertical height of the fluidized bed reactor 3 . The vertical distance from the bottom of the regenerator 11 between the connecting port of the inclined pipe 13 to be produced and the regenerator 11 is 1 / 20 of the vertical height of the regenerator 11 . Using SAPO-34 molecular sieve a...

Embodiment 2

[0023] use figure 1 The multi-reaction zone combined reactor, wherein the vertical distance between the raw material inlet B15 and the bottom of the first riser reactor 4 is 1 / 25 of the height of the first riser reactor 4 . The inner diameter of the first riser reactor 4 is 1 / 4 of the inner diameter of the fluidized bed reactor 3 , and the height of the first riser reactor 4 is 5 times the height of the fluidized bed reactor 3 . The height of the first riser reactor 4 is 0.8 times the height of the second riser reactor. The vertical height of the connecting port between the regeneration inclined pipe 16 and the fluidized bed reactor 3 from the bottom of the fluidized bed reactor 3 is 1 / 12 of the vertical height of the fluidized bed reactor 3 . The vertical distance from the bottom of the regenerator 11 between the connecting port of the inclined pipe 13 to be produced and the regenerator 11 is 1 / 20 of the vertical height of the regenerator 11 . Using SAPO-34 molecular sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com