Algae-removing water-purifying agent and preparation method thereof

A technology of algae water purifier and diatomite, which is applied in the field of purification, can solve the problems of large amount of capital and time-consuming, etc., and achieve the effect of being practical, advanced, easy to use, and low in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

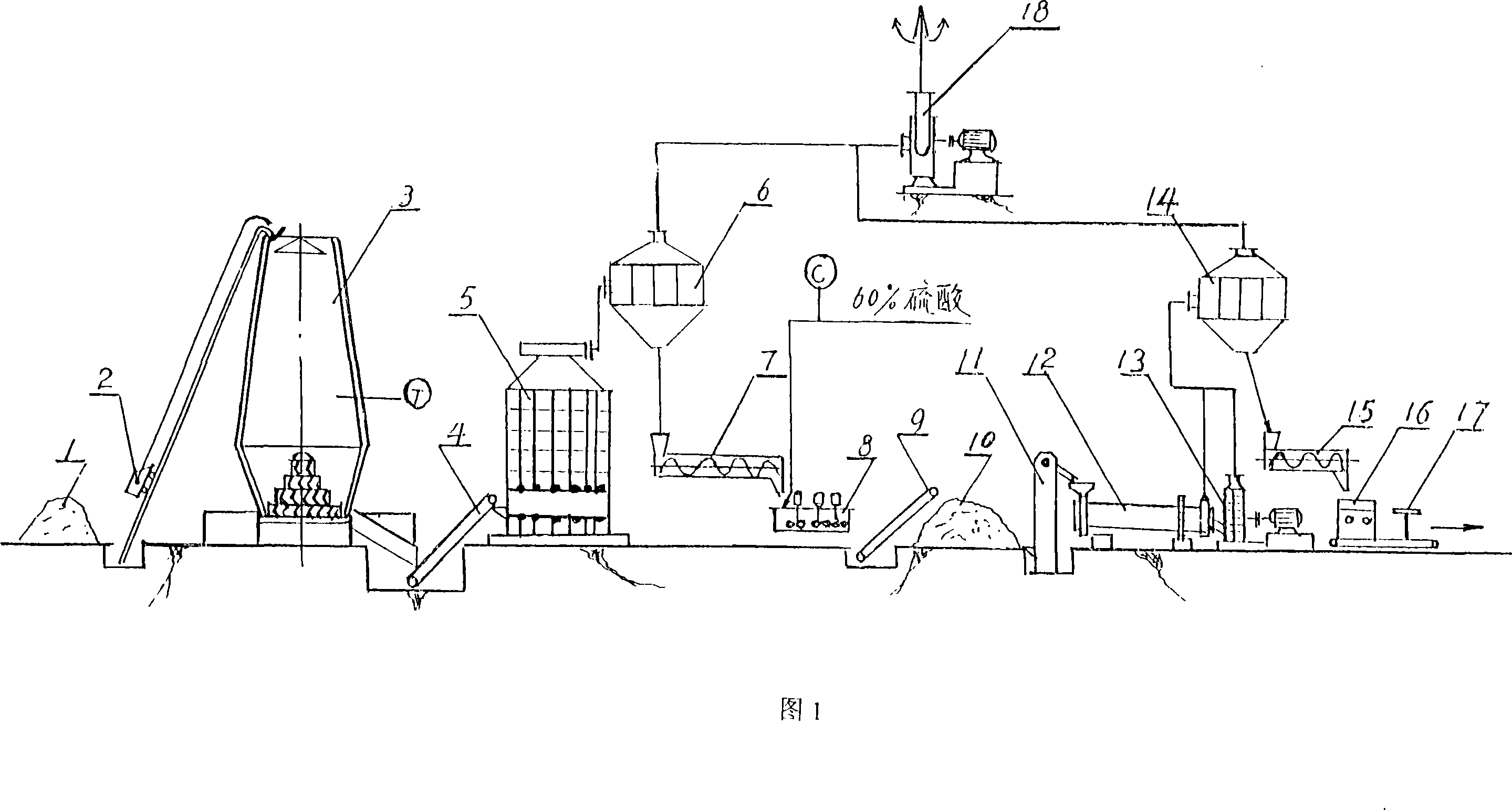

[0034] Qualified diatomite ore raw materials (SiO 2 Content 50~70%, Al 2 o 3 Content ≥ 8%, Fe 2 o 3 ≤10%, based on Pu, heavy metal content ≤0.05%, organic matter content 7-15%) are sent into shaft kiln 3, and the temperature is controlled at 750-800° C. by combustion of organic matter. Decompose organic matter and carbonate, activate kaolinite in diatomite ore, and the ore after roasting for 3 hours is discharged from the lower part of the shaft kiln after being cooled by air. The roasted and cooled material is sent to the vertical mill 5 by the leather conveyor 4, and the crushed powder is sent to the upper powder selector by the exhaust fan 18. In the powder separator, quartz, feldspar, and iron ore are too hard to be finely ground, so the coarser particles are blocked and removed, and the diatomite can be purified. The purified diatomite is separated from gas and solid by a bag dust collector, and the powdery diatomite is fed quantitatively by a screw conveyor 7, and t...

Embodiment 2

[0037] Another qualified diatomite ore raw material (SiO 2 Content 50~70%, Al 2 o 3 Content ≥ 8%, Fe 2 o 3 ≤10%, based on Pu, heavy metal content ≤0.05%, organic matter content 5-15%) is sent into shaft kiln 3, and the temperature is controlled at 600-650° C. by combustion of organic matter. Decompose organic matter and carbonate, activate kaolinite in diatomite ore, and the ore after roasting for 2 hours is discharged from the lower part of the shaft kiln after being cooled by air. The roasted and cooled material is sent to the vertical mill 5 by the leather conveyor 4, and the crushed powder is sent to the upper powder selector by the exhaust fan 18. In the powder separator, quartz, feldspar, and iron ore are too hard to be finely ground, so the coarser particles are blocked and removed, and the diatomite can be purified. The purified diatomite is separated from gas and solid by a bag dust collector, and the powdery diatomite is fed quantitatively by a screw conveyor 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com