High precision star simulator

A star simulator and high-precision technology, applied in the field of star simulators, can solve the problems of low precision and high cost, and achieve the effects of high simulation precision, improved performance and reduced coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

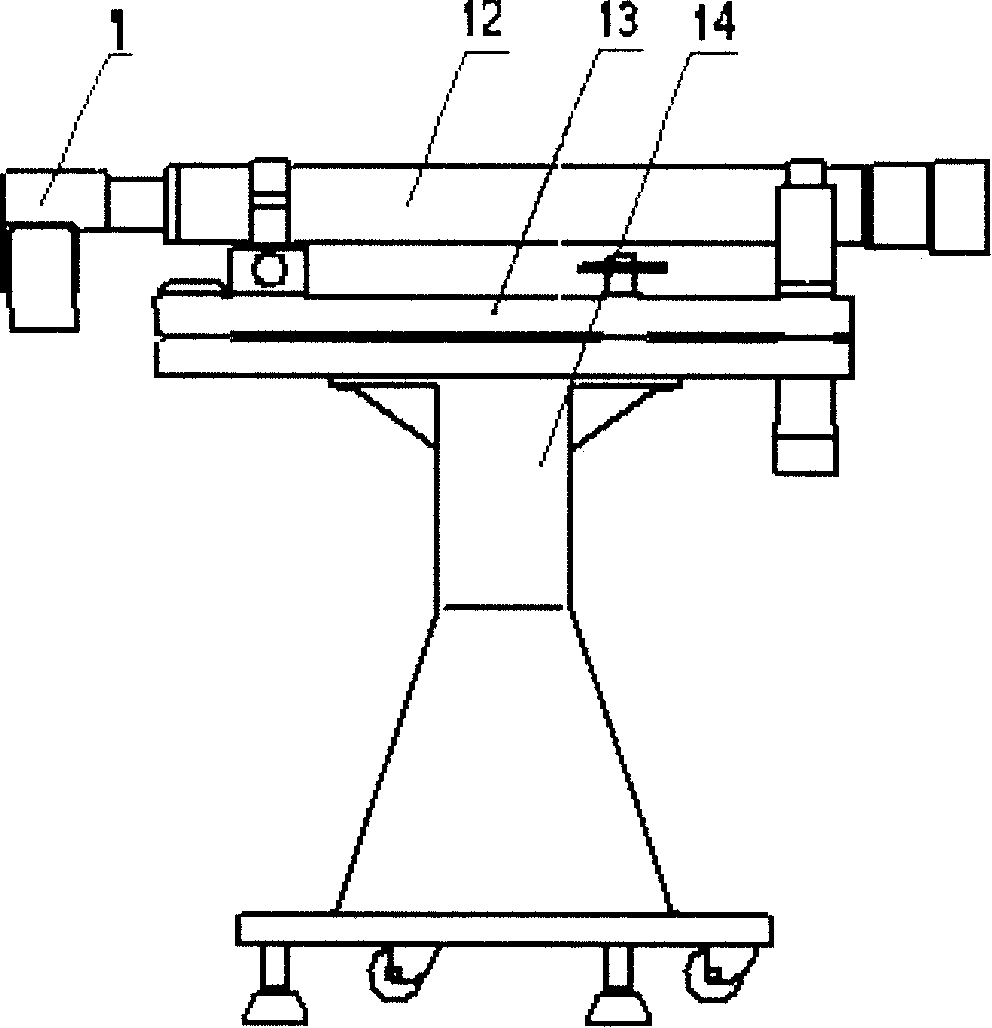

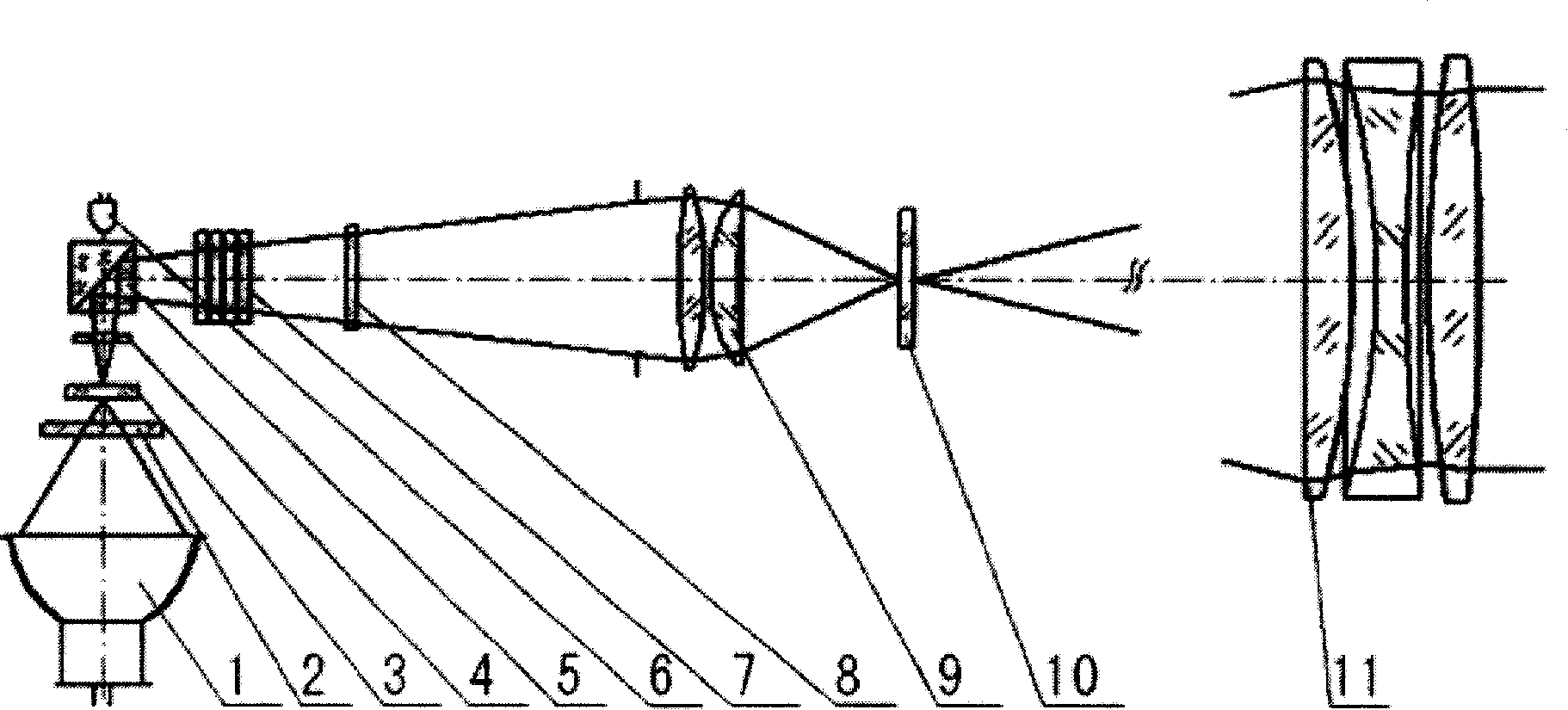

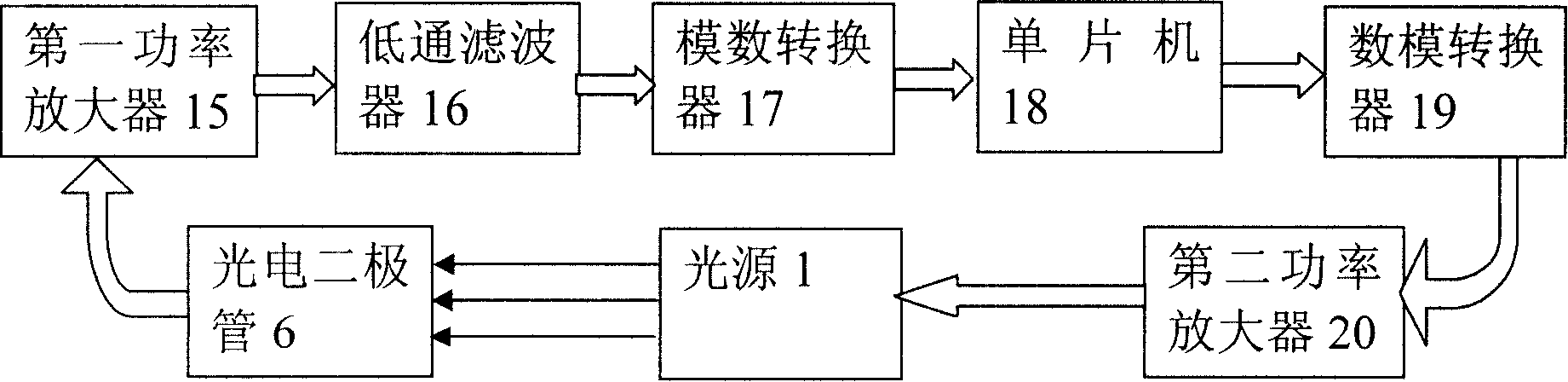

[0026] A specific embodiment of the present invention see figure 2 , including the light source and the infrared reflector, frosted glass, condenser A, cemented prism, attenuation sheet group, filter, condenser B, star point plate and collimator arranged on the light path in sequence; the light source adopts a combined halogen tungsten bulb, its The parameters are: voltage 12V, power 35W, luminous intensity 5000cd, average lifespan 1000h; the combined tungsten halogen bulb emits a lot of infrared rays, in order to reduce the temperature near the star point, an infrared reflector is used to reflect the infrared rays emitted by the bulb back and dissipate heat; Because most of the light energy gathered by the bulb on the frosted glass is within 8mm in diameter, the light concentrating system concentrates the light with the same angle within this range on a point on the star point board, that is, every point of the light spot on the star point board is ground glass The result of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com