Extractive agent for recycling acetic acid in dilute acetic acid

A technology of dilute acetic acid and extractant, applied in liquid solution solvent extraction, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low separation efficiency and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

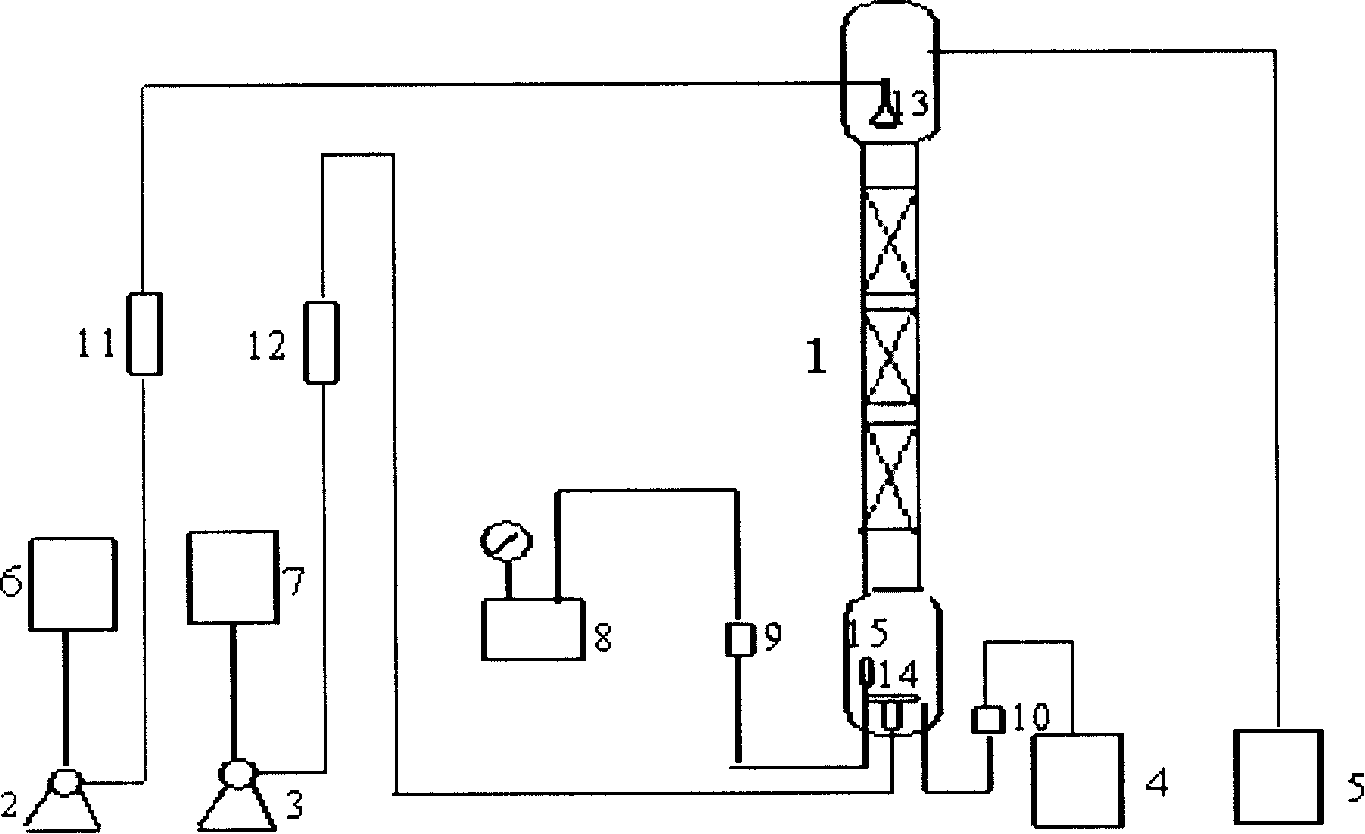

[0018] according to figure 1 Shown: the extraction tower is filled with 3 mm × 3 mm θ ring wire mesh packing, the effective height is 1.2 meters, the weight percentage of acetic acid in the dilute acetic acid solution is 3.3%, the percentage of water is 96.7%, the dilute acid solution and the extraction agent Both enter the top and bottom of the extraction tower at a flow rate of 0.7 kg / h, the extraction temperature is 35°C, the air compressor pressure is 150kPa, and the pulse frequency of the solenoid valve is 0.05 seconds -1 , change the composition of the extractant, and analyze the extract phase and raffinate phase after the operation is stable.

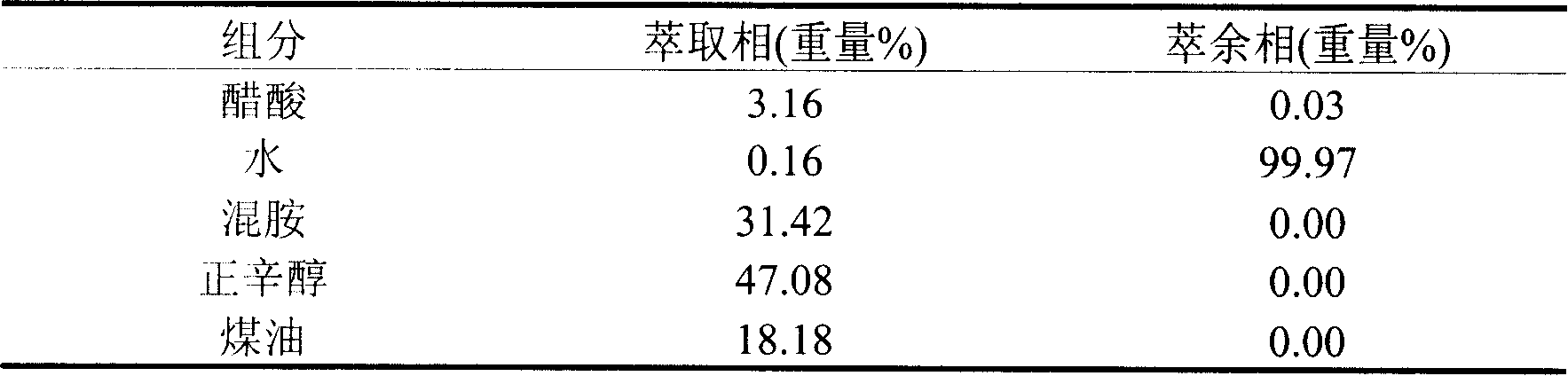

[0019] 1) When the weight percentage of extractant: mixed amine (wherein tributylamine and tripentylamine respectively account for 35% and 65%, hereinafter the same) is 32.5%, n-octanol is 48.7%, kerosene fraction above 160 ℃ is At 18.8%, the extraction result is:

[0020] Extraction result

[0021]

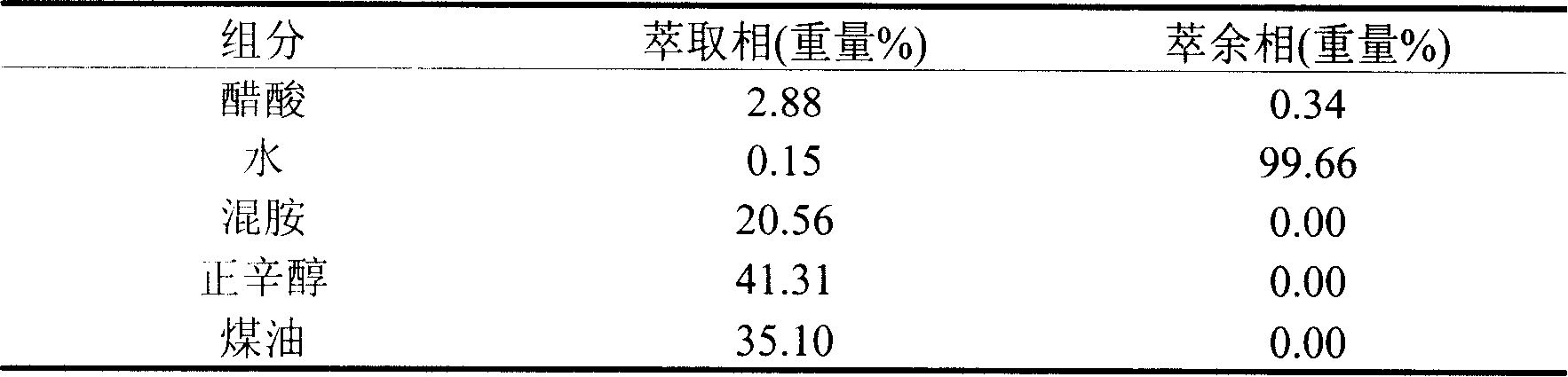

[0022] 2) When the mix...

Embodiment 2

[0029] Keep other conditions as in Example 1, change the type of n-alkanol in the extractant component, and its weight percentage is still 48.7%, after the system is stable, analyze the extract phase and the raffinate phase.

[0030] 1) When n-alkanol is n-heptane, the extraction result is:

[0031] Extraction result

[0032]

[0033] 2) When n-alkanol is n-nonanol, the extraction result is:

[0034] Extraction result

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com