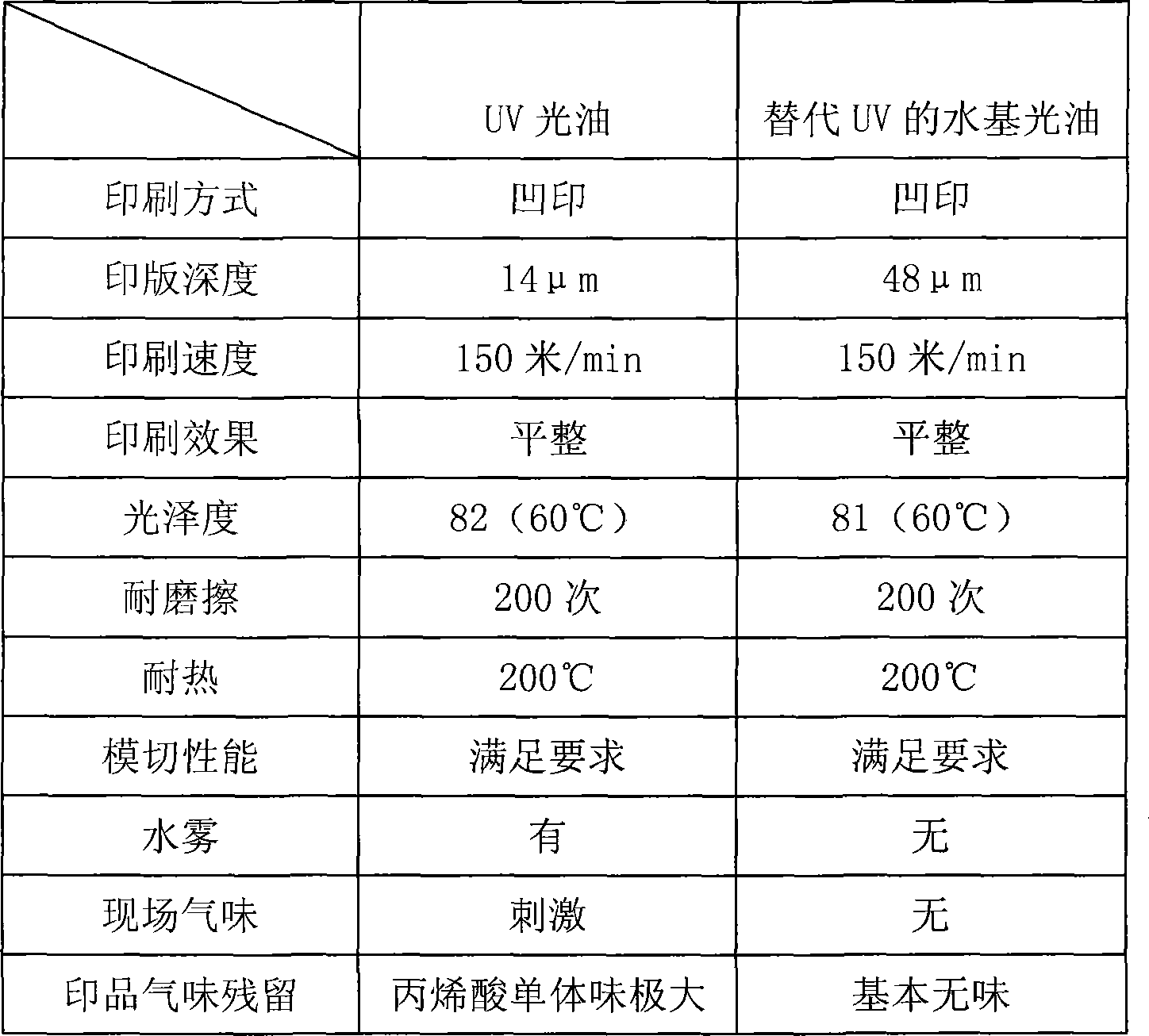

Water-based gloss oil substituting UV gloss oil

A varnish and water-based technology, applied in the direction of coating, latex paint, etc., can solve the problems of overshooting, slow drying, large latent heat of evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A water-based varnish that replaces UV varnish is made of the following components in proportion by weight:

[0025] Water-based acrylic emulsion (model NeoCryl A-1092) 85%

[0026] Substrate wetting agent (model is Wet 500) 0.5%

[0027] Defoamer (model is Foamex 1488) 0.2%

[0028] Slip agent (model is Ultralube E668H) 5%

[0029] Crosslinker 4%

[0030] Propylene Glycol Methyl Ether 1%

[0031] Ethanol 3%

[0032] Water 1.3%

[0033] The above-mentioned manufacturing process of a water-based varnish replacing UV varnish is: according to the order of water-based acrylic emulsion, substrate wetting agent, defoamer, slip agent, crosslinking agent, propylene glycol methyl ether, ethanol and water Order, add while stirring, and fully stir evenly.

Embodiment 2

[0035] A water-based varnish that replaces UV varnish is made of the following components in proportion by weight:

[0036] Modified acrylic emulsion (model JonCryl 74) 92%

[0037] Substrate wetting agent (model is Wet 500) 0.5%

[0038] Defoamer (model is Foamex 822) 2%

[0039] Slip agent (model is Dowcorning 51) 0.5%

[0040] Ethylene glycol ether 1%

[0041] Isopropanol 3%

[0042] Water1%

[0043] The manufacturing process of the above-mentioned water-based varnish that replaces UV varnish is: in the order of modified acrylic emulsion, substrate wetting agent, defoamer, slip agent, ethylene glycol ether, isopropanol and water , add while stirring, and fully stir evenly.

Embodiment 3

[0045] A water-based varnish that replaces UV varnish is made of the following components in proportion by weight:

[0046] Water-based acrylic resin solution (model is NeoCryl A-1049 74.8%

[0047] Substrate wetting agent (model is Wet 505) 0.2%

[0048] Defoamer (model is Foamex 1488) 1%

[0049] Slip agent (model Ultralube E668H) 8%

[0050] Cross-linking agent 2%

[0051] Ethylene glycol butyl ether 1%

[0052] n-propanol 8%

[0053] water 5%

[0054] The above-mentioned manufacturing process of a kind of water-based varnish replacing UV varnish is: according to water-based acrylic resin solution, substrate wetting agent, defoamer, slip agent, crosslinking agent, ethylene glycol butyl ether, n-propylene Alcohol and water in sequence, add while stirring, and fully stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com