Waterless washing method and waterless laundry device

A laundry device and washing method technology, applied to washing devices, other washing machines, chemical instruments and methods, etc., can solve problems such as inability to get rid of water dependence, achieve strong antibacterial and bactericidal effects, and protect water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

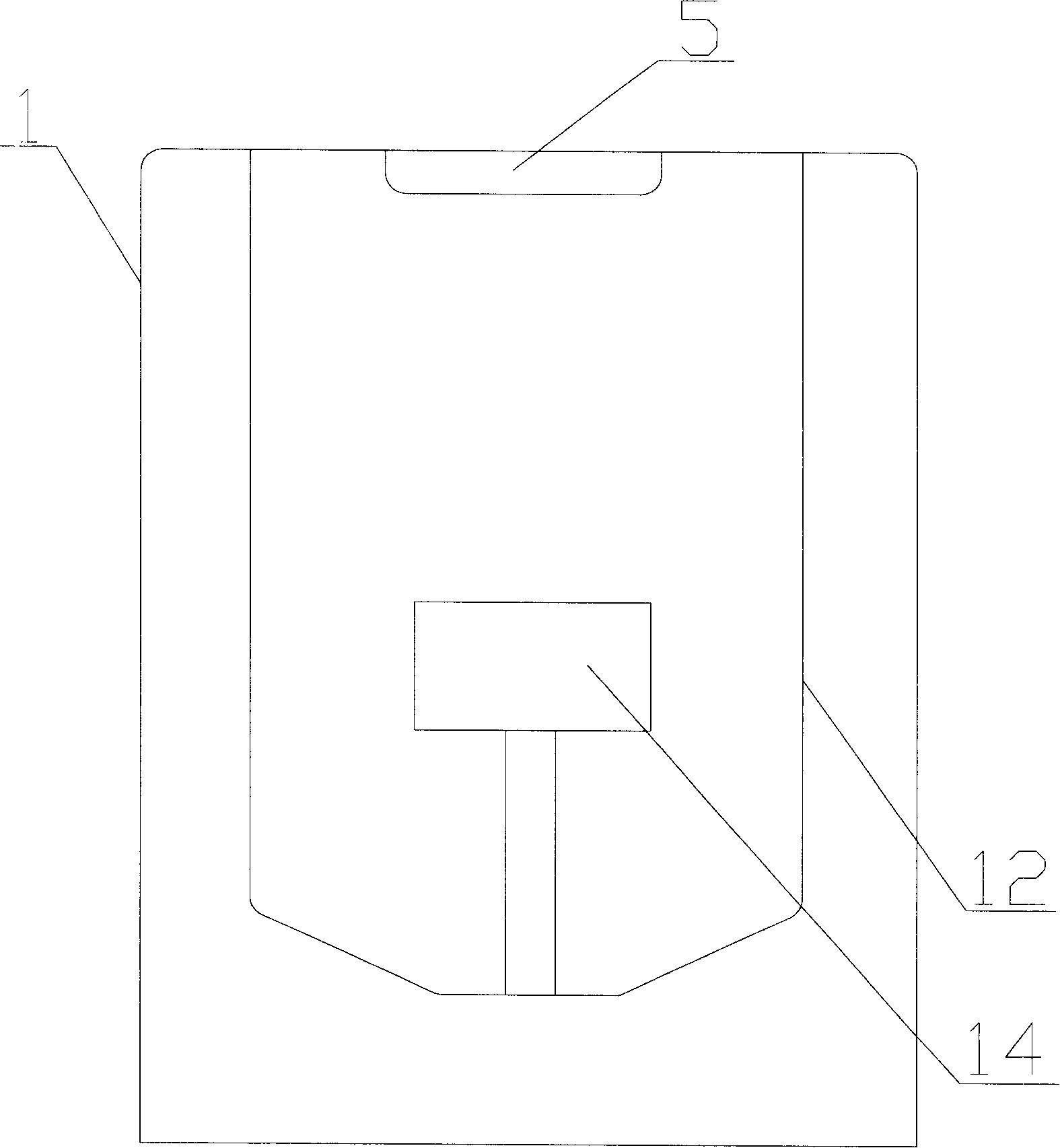

[0038] See attached figure 1. The waterless laundry device of this embodiment includes a box body 1 , a container 12 and a light emitting device 5 . The position in the center of the container 12 is provided with a box 14 with holes on the surface and a photocatalyst is housed, wherein the main component of the photocatalyst is WO 3 . The light emitting device 5 is arranged inside the top of the container, and in this embodiment is an ordinary fluorescent lamp. The water molecules and oxygen molecules in the air are catalyzed by the photocatalyst under the light irradiation to generate hydroxyl radicals and ozone. The dirt on the clothes is in contact with hydroxyl radicals and active oxygen, the organic components are finally oxidized into carbon dioxide and water, and the inorganic components are oxidized into gaseous substances or high-valence molecules, and the remaining solid substances are separated from the clothes under the action of gravity. Since both hydroxyl ra...

Embodiment 2

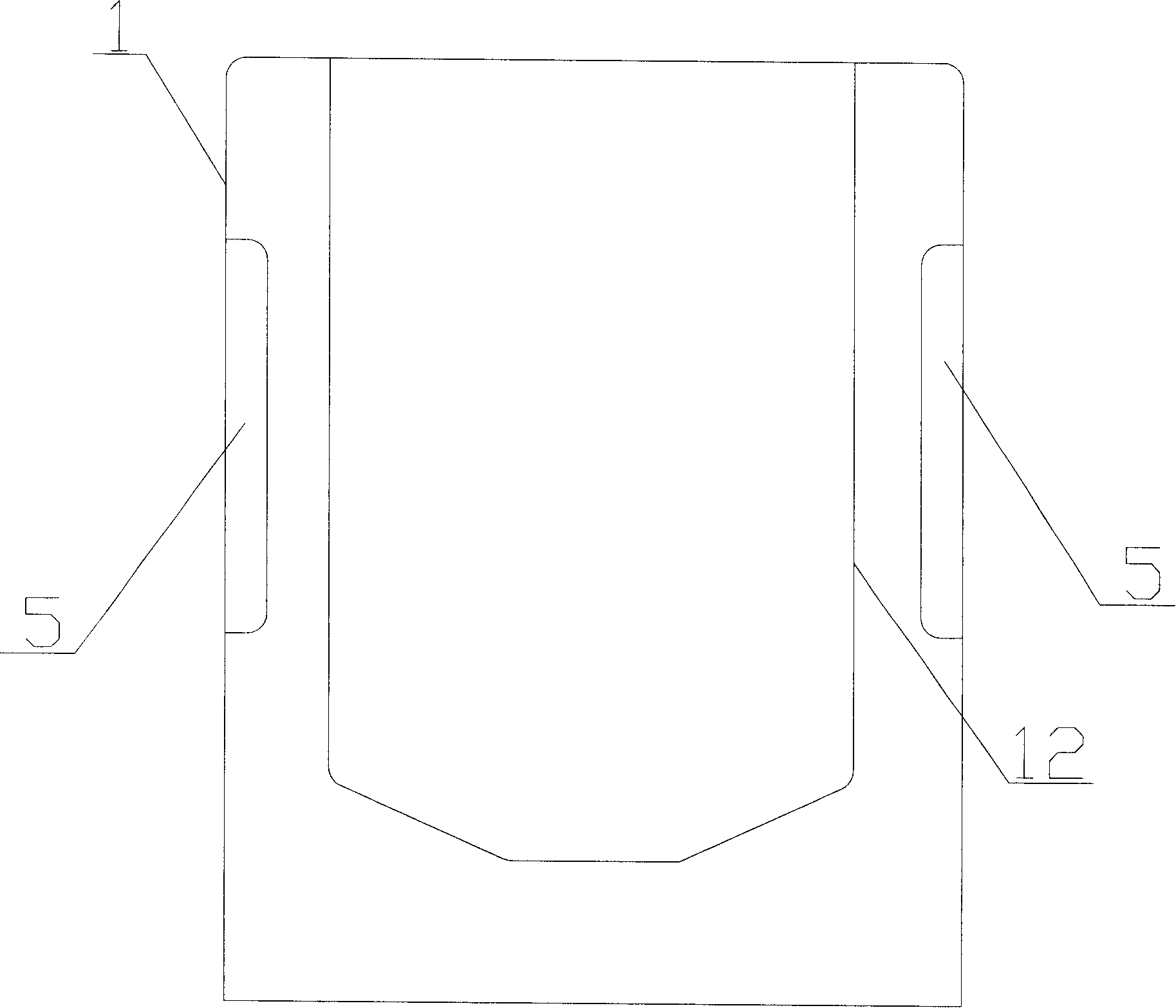

[0040] See attached figure 2 . On the basis of embodiment 1, the container 12 of embodiment 2 is provided with hole, and photocatalyst thin film main component is titanium dioxide, is formed on the inwall of container 12 by plasma spraying, and light-emitting device 5 is common fluorescent lamp, is arranged on container 12 and Between the boxes 1 , the light emitted by the light emitting device 5 is irradiated onto the photocatalyst film in the container 12 through the holes on the container. The decontamination, disinfection and deodorization of clothes are completed through the generated hydroxyl radicals and active oxygen.

Embodiment 3

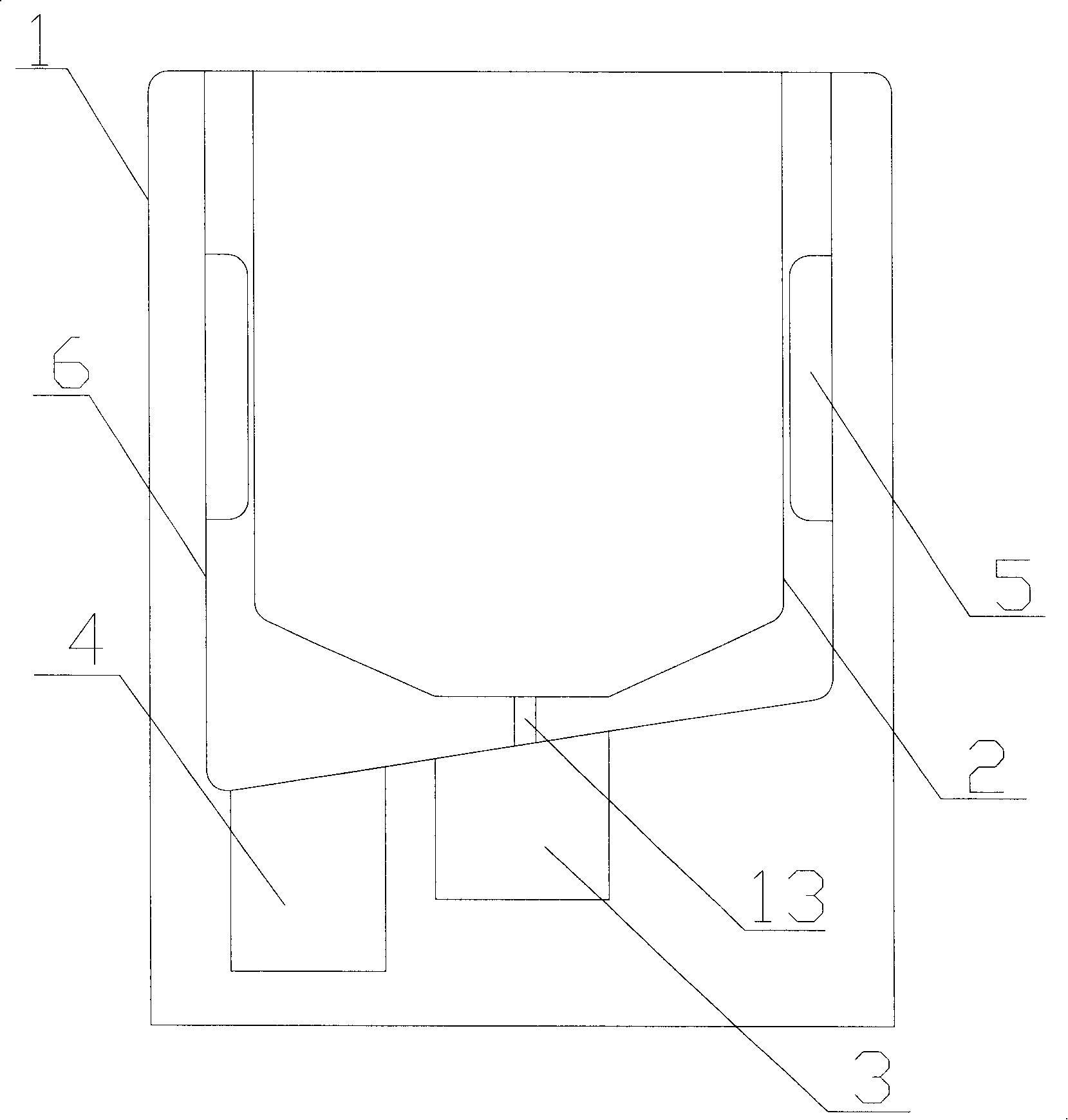

[0042] See attached image 3 . On the basis of Example 2, the container of Example 3 is composed of an outer tub 6 and an inner tub 2. The inner tub 2 accommodates the laundry and is driven by the power unit 3 to rotate along the rotating shaft 13. The surface of the inner tub 2 is provided with holes. The power device 3 in this embodiment is an electric motor, and the rotation can be a circular rotation or a left-right circular rotation. A nano-scale titanium dioxide photocatalyst film is attached to the inner wall of the inner barrel 2, and the film is formed by coating a titanium dioxide nano-coating. The dust collecting device 4 is arranged between the inner barrel 2 and the box body 1, and is a bag dust collector in this embodiment. The light emitting device 5 is an ultraviolet lamp capable of generating active oxygen. When in use, put the clothes into the inner barrel 2, turn on the power, the inner barrel 2 starts to rotate, and drives the clothes in it to move, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com