Gas injection apparatus

A technology of gas injection and gas passage, applied in the direction of electrical components, plasma, gaseous chemical plating, etc., can solve the problems of large air flow, large divergence angle, and uneven spraying of air flow, and achieve large area, uniform gas distribution, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

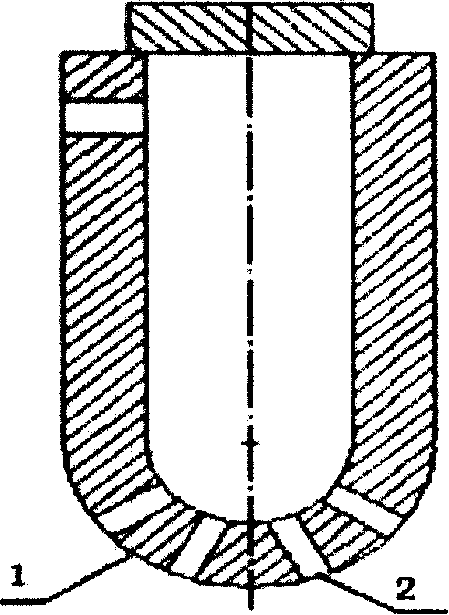

[0028] The gas injection device of the present invention is used to supply gas to the reaction chamber. The reaction chamber may be a reaction chamber of an inductively coupled plasma device, or a reaction chamber of other semiconductor processing equipment, or other cavities.

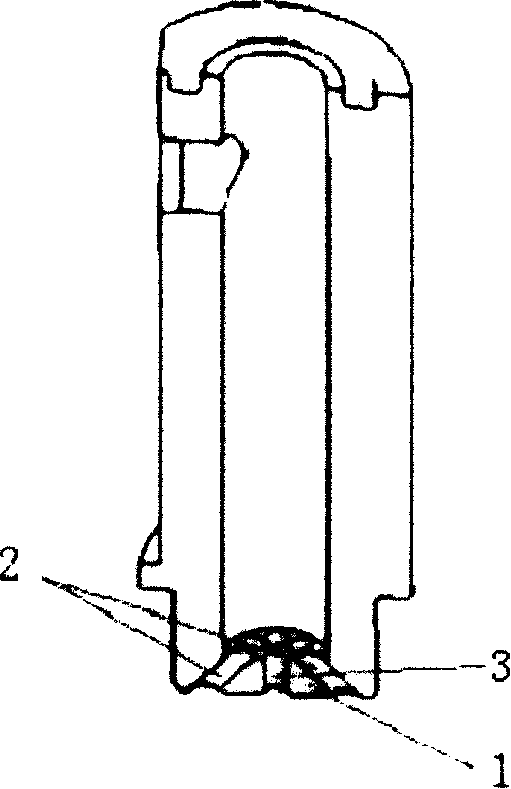

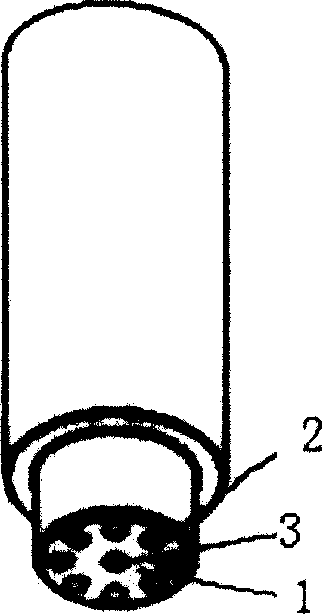

[0029] Such as Figure 4 As shown, the gas injection device of the present invention includes a body 5, a gas passage 4 is arranged in the body 5, a nozzle 6 with an arc surface is provided at the front end of the body 5, and a plurality of gas injection holes are arranged along the arc of the nozzle 6, and the gas Pass through the gas channel 4 and spray into the reaction chamber through the gas injection hole.

[0030] Such as Figure 6 As shown, the nozzle 6 is preferably hemispherical. Other arc shapes are also possible.

[0031] The diameter of the jet hole is 0.3-0.7 mm, preferably 0.3, 0.4, 0.5, 0.6, 0.7 mm, etc., preferably 0.4-0.6 mm, most preferably 0.5 mm. This size is smaller than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com