Combined edging stirring friction welding agitator head

A technology of friction stir welding and stirring head, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of unfavorable modification of size and practicability, waste of materials, and influence on smooth progress, so as to improve practicability and convenience Removal or replacement, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

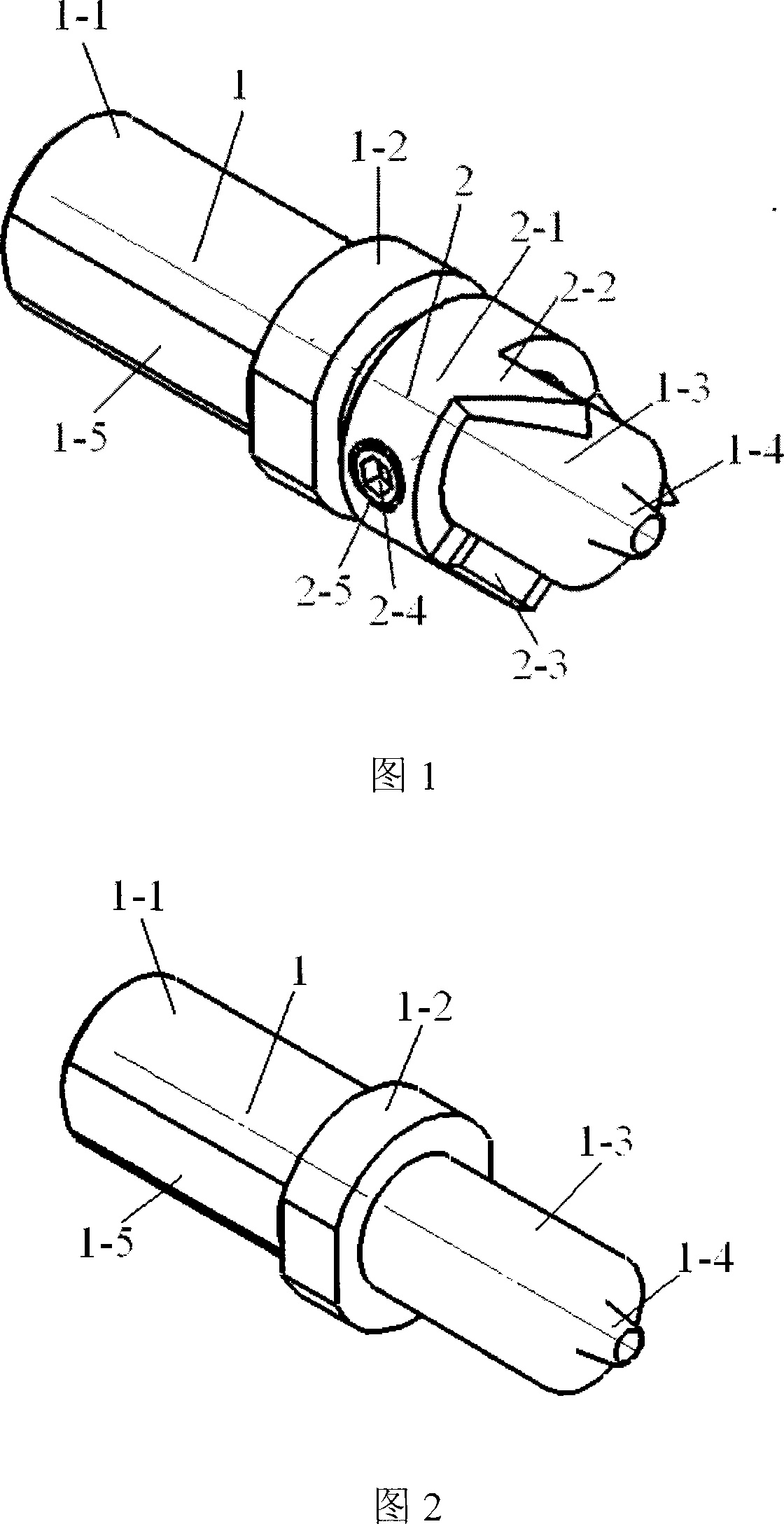

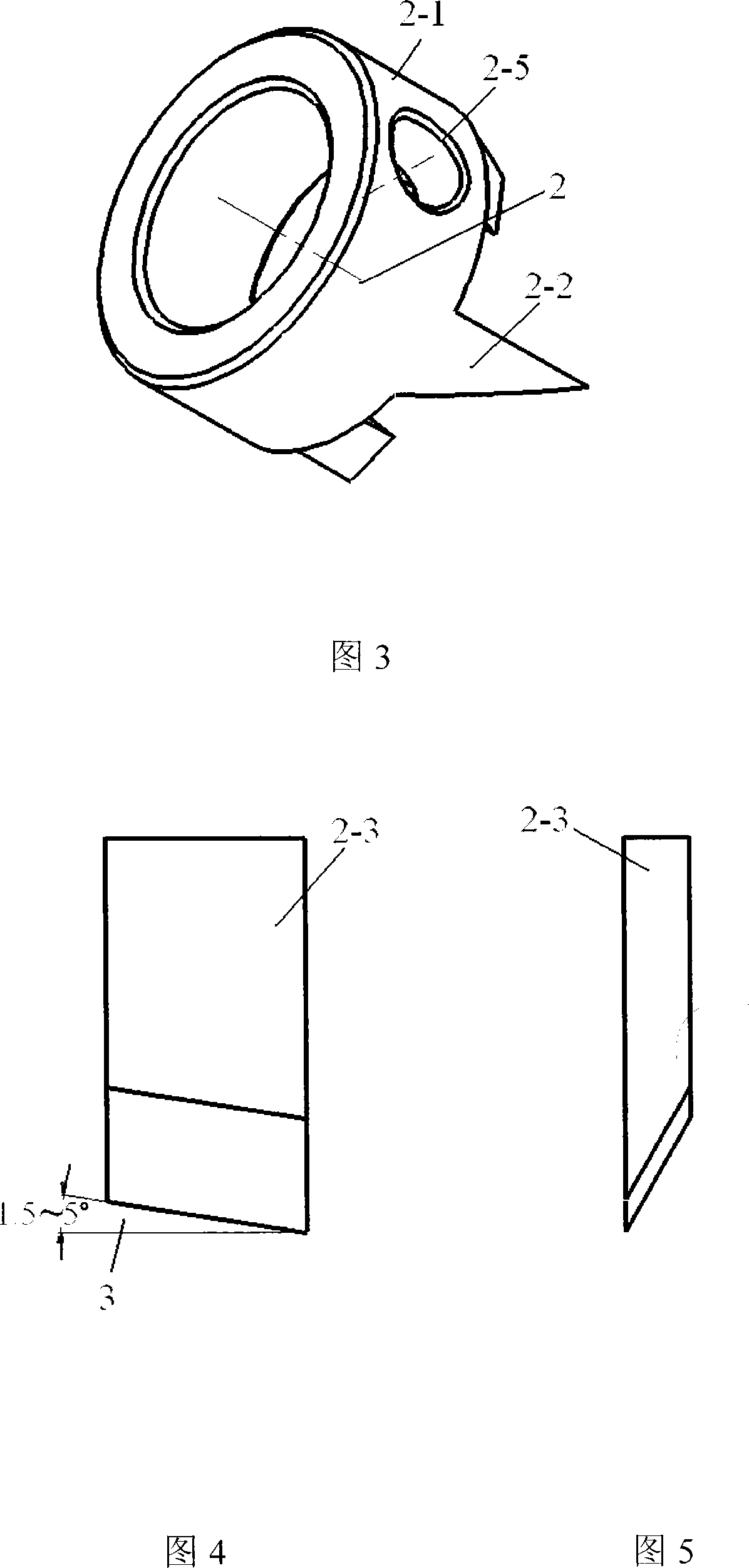

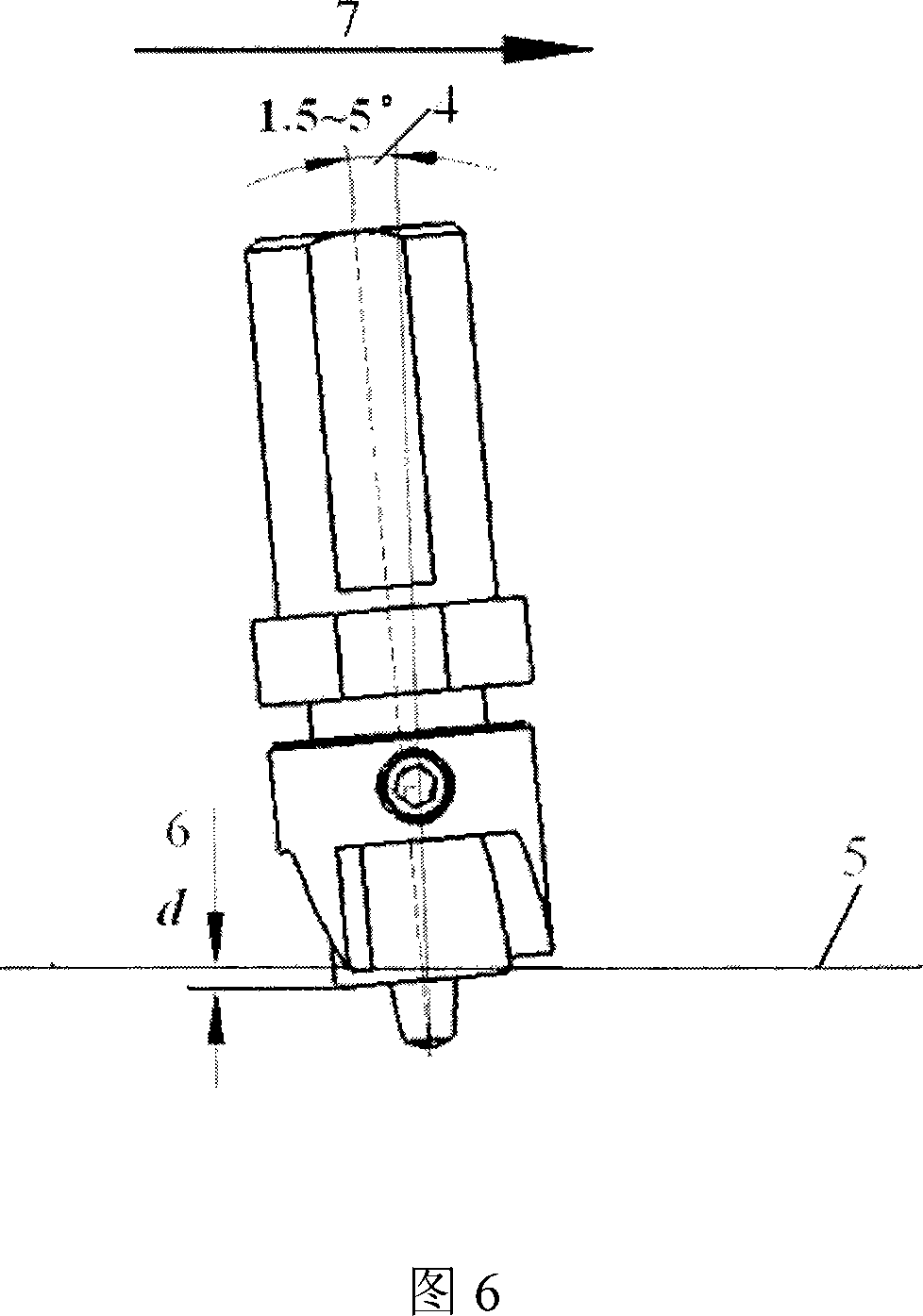

[0027] This embodiment will be described with reference to FIG. 1 , FIG. 2 , FIG. 3 , FIG. 4 , and FIG. 5 . In this embodiment, the welding parameters of the friction stir welding are that the welding inclination 4 is 1.5°, and the indentation 6 of the stirring head relative to the surface 5 of the material to be welded is 0.15 mm. The friction stir welding stirring head is a split structure, which consists of a stirring head base and a cutting tool body. The stirring head matrix includes clamping poke 1-1, shoulder 2, shaft shoulder 1-3 and stirring needle 1-4 and so on. Cutting tool body is made up of installing ring 2-1, cutting tool seat 2-2, cutting blade 2-3 and set screw 2-4 etc. The clamping poke 1-1 of the stirring head base is milled with a clamping plane 1-5, which is fixed on the main shaft of the friction stir welding machine with set screws, and screws of different specifications can be selected according to specific conditions to provide sufficient fastening fo...

Embodiment 2

[0029] This embodiment will be described with reference to FIG. 5 . In this embodiment, the welding parameters of the friction stir welding are that the welding inclination 4 is 5°, and the indentation 6 of the stirring head is 0.1 mm. The main structural form of the combined deflashing mixing head proposed by the present invention adopted in this embodiment is the same as that of Embodiment 1, the difference is that the cutting tool body has two cutting tool seats, which are symmetrical along the circumferential direction of the installation ring Distribution, one side of the cutting tool seat is a slope, the slope angle is 85°, the slope is inlaid with cutting blades 2-3, the blade surface slope angle 3 is 5°, adjust the cutting body to move up and down along the axis of the mixing head, so that the cutting blade The shoulder edge distance of the noodle stirring head is 0.1mm.

Embodiment 3

[0031]This embodiment will be described with reference to FIG. 2 and FIG. 5 . In this embodiment, the material 5 to be welded by friction stir welding is titanium alloy, and the welding direction 7 is shown in FIG. 5 . The welding parameters are that the welding inclination angle 4 is 2.5°, and the indentation amount 6 of the stirring head is 0.08mm. The main structural form of the combined deflashing stirring head proposed by the present invention used in this embodiment is the same as that in Embodiment 1, except that the stirring head base 1 shown in FIG. 2 is a tungsten-rhenium superalloy material. The cutting tool body has 4 cutting tool holders, which are evenly distributed along the circumferential direction of the installation ring. One side of the cutting tool holder is a bevel, and the inclination angle of the bevel is 65 degrees. 2.5°, adjust the cutting tool body to move up and down along the axis of the mixing head, so that the distance between the edge of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com