Three-dimensional electrode reactor and method for processing chlorobenzene waste water by using the same

A technology of three-dimensional electrodes and reactors, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of microbial influence, high toxicity of chlorobenzene, low treatment efficiency, etc., and achieve high efficiency Degradation, increased surface area, strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

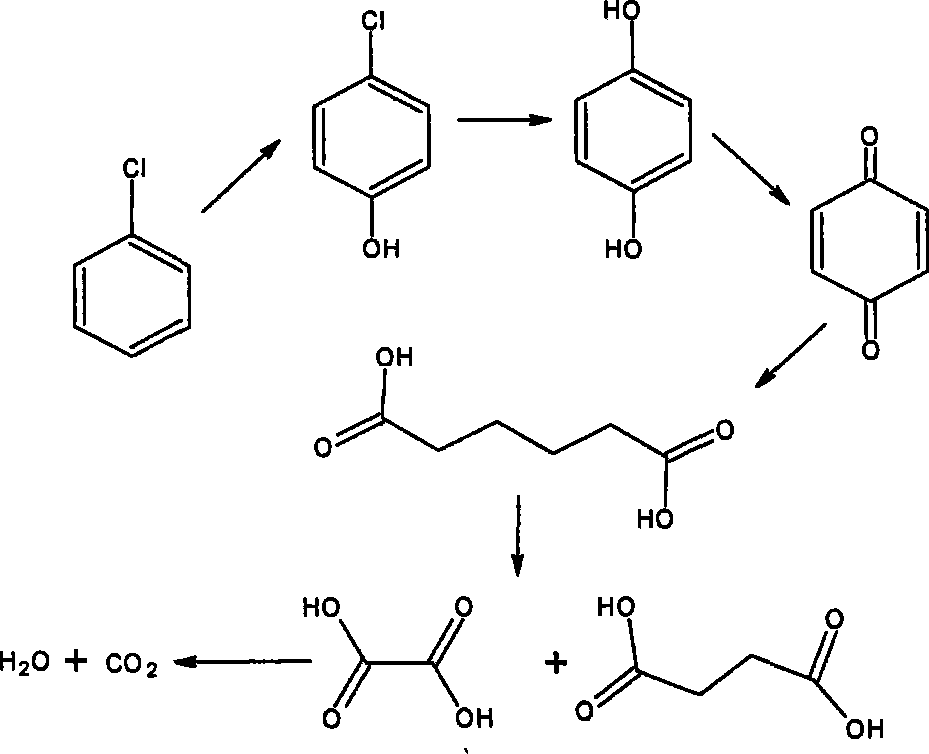

[0026] As shown in Fig. 2, the three-dimensional electrode reactor 4 of the present invention is a closed cylindrical container, the center of the bottom is provided with a columnar graphite anode, the sidewall is a stainless steel cathode, and the activated carbon of the antimony dioxide catalyst is filled between the columnar graphite and the sidewall. The graphite and the side wall are connected to a DC stabilized power supply. Chlorobenzene wastewater can be injected into the three-dimensional electrode reactor 4 from the raw water tank 1 through the water inlet pump 2 and the glass rotameter 3. The DC stabilized power supply 6 controls the voltage and current of the three-dimensional electrode reactor 4, and the valve 7 can control the waste water During the residence time in the three-dimensional electrode reactor 4, the treated tail water is discharged into the effluent storage tank 5, and then it can be directly discharged or further processed for biochemical advanced t...

Embodiment 2

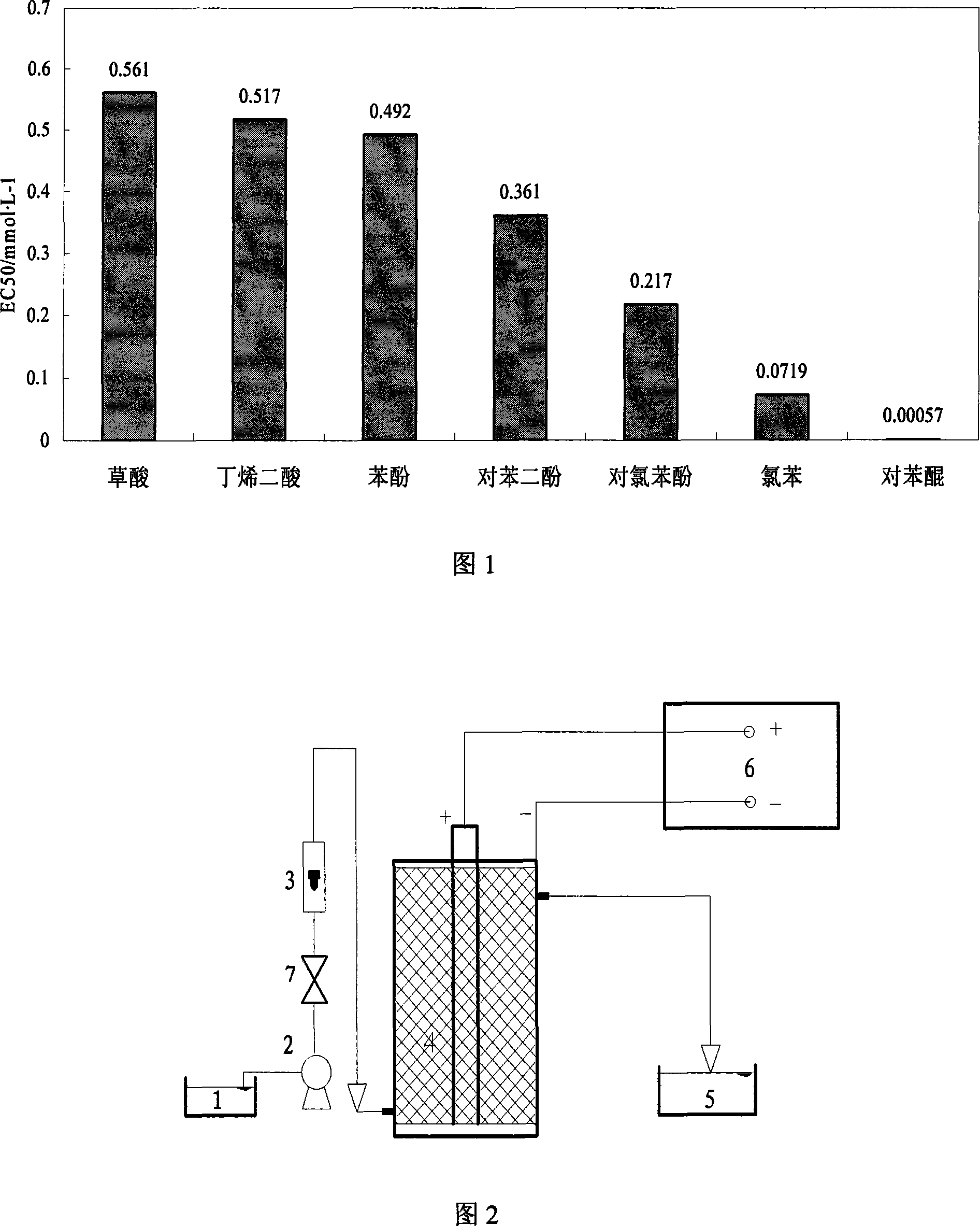

[0028] Influent chlorobenzene concentration is 100mg / L, influent toxicity EC 50 is 10.98%, the control current intensity is 1.0A, and the residence time is 120min. After being degraded by the three-dimensional electrode reactor, the main components of the effluent are butenedioic acid and oxalic acid, the concentration of chlorobenzene is 4.5mg / L, and the relative opacity is 5.3%. The degradation water is low in toxicity.

Embodiment 3

[0030] Influent chlorobenzene concentration is 112.5mg / L, influent toxicity EC 50 is 11.68%, the control current intensity is 2.0A, and the residence time is 60min. After being degraded by the three-dimensional electrode reactor, the main components in the effluent are butenedioic acid and oxalic acid, the concentration of chlorobenzene is 1.5mg / L, and the relative opacity is 0. The effluent is non-toxic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com