Transmittance pulsation method granule measuring method and its device

A measurement method and technology of transmittance, applied in the field of particle measurement method and device of transmittance pulsation method, capable of solving problems such as difficult data processing and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

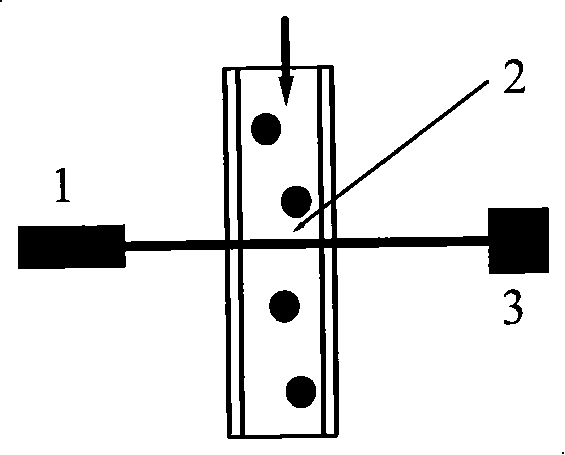

[0095] Depend on Figure 4 As shown, the narrow beam generator is composed of a laser 19 for generating parallel beams, a beam expander 22 , and a convex lens or lens group 23 . The beam emitted by the laser 19 passes through the beam splitter 20 and the beam expander 22, and then converges through the convex lens or lens group 23 to obtain a narrow beam in the Rayleigh region near the focal point. The transmitted light after the narrow beam passes through the measurement area 2 is received by the photodetector 3 after passing through the receiving lens 24 . A beam splitter 20 and a reference light detector 21 are used to monitor fluctuations in incident light intensity.

Embodiment 2

[0097] Depend on Figure 5 As shown, it includes a laser 19, a beam splitter 20, a reference light detector 21, and a beam expander 22. The narrow beam generator in this embodiment is composed of a diaphragm or an optical fiber arranged at the optical signal transmitting end and the optical signal receiving end. A narrow beam is obtained by a diaphragm or an optical fiber arranged in the direction of propagation of the broad beam emitted by the laser. The aperture is set as a front aperture 25 and a rear aperture 26, both of which can be selected or used in combination. The wide beam emitted by the laser 19 passes through the front aperture 25 to form a narrow beam, and the transmitted light after passing through the measurement area 2 is received by the photodetector 3 or the transmitted light after the wide beam emitted by the laser 19 passes through the measurement area 2 passes through the rear aperture 26 is received by photodetector 3.

Embodiment 3

[0099] Depend on Image 6 As shown, it includes a laser 19 , a beam splitter 20 , a reference light detector 21 , a beam expander 22 , a measurement area 2 and a photodetector 3 . The characteristic is that the narrow beam generator described in this embodiment consists of a laser 19, a beam splitter 20, a beam expander 22 and a narrow beam guide using a microaperture diaphragm or an optical fiber placed in front of the transmitted light detector 3 27 or composed of a laser generating parallel light beams and a micro-element signal detector, the micro-element photodetector is composed of a photodetection unit made of silicon light film material with a small light-receiving area.

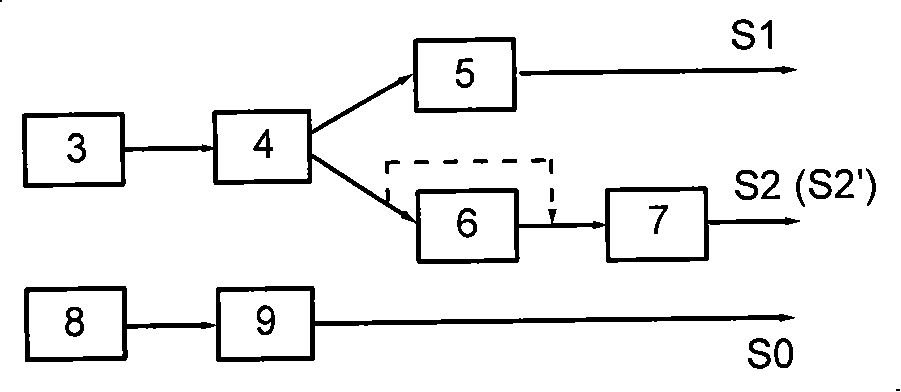

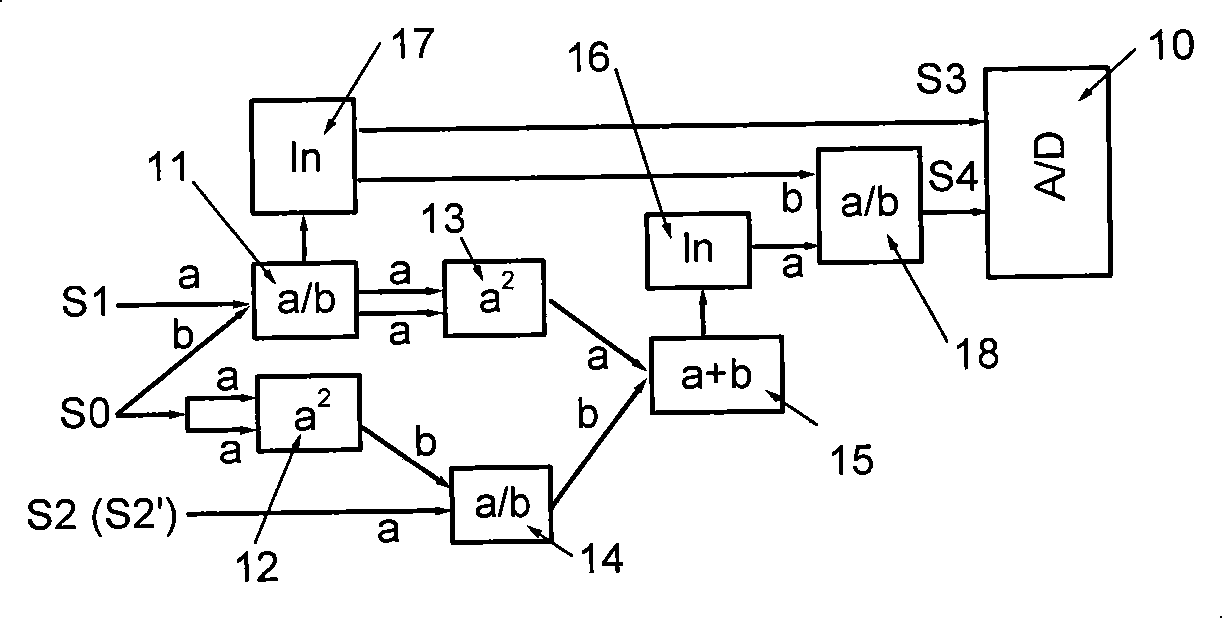

[0100] Depend on figure 2 , image 3 As shown, the signal processing device includes an analog signal processor and a signal subsequent processor.

[0101] Described analog signal processor is made up of amplifier, low-pass filter, high-pass filter and root-mean-square RMS processor, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com