Electric power conversion device

A technology for power conversion devices and power converters, which is applied to output power conversion devices, electrical components, and conversion of AC power input to DC power output. Effects of Harmonic Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

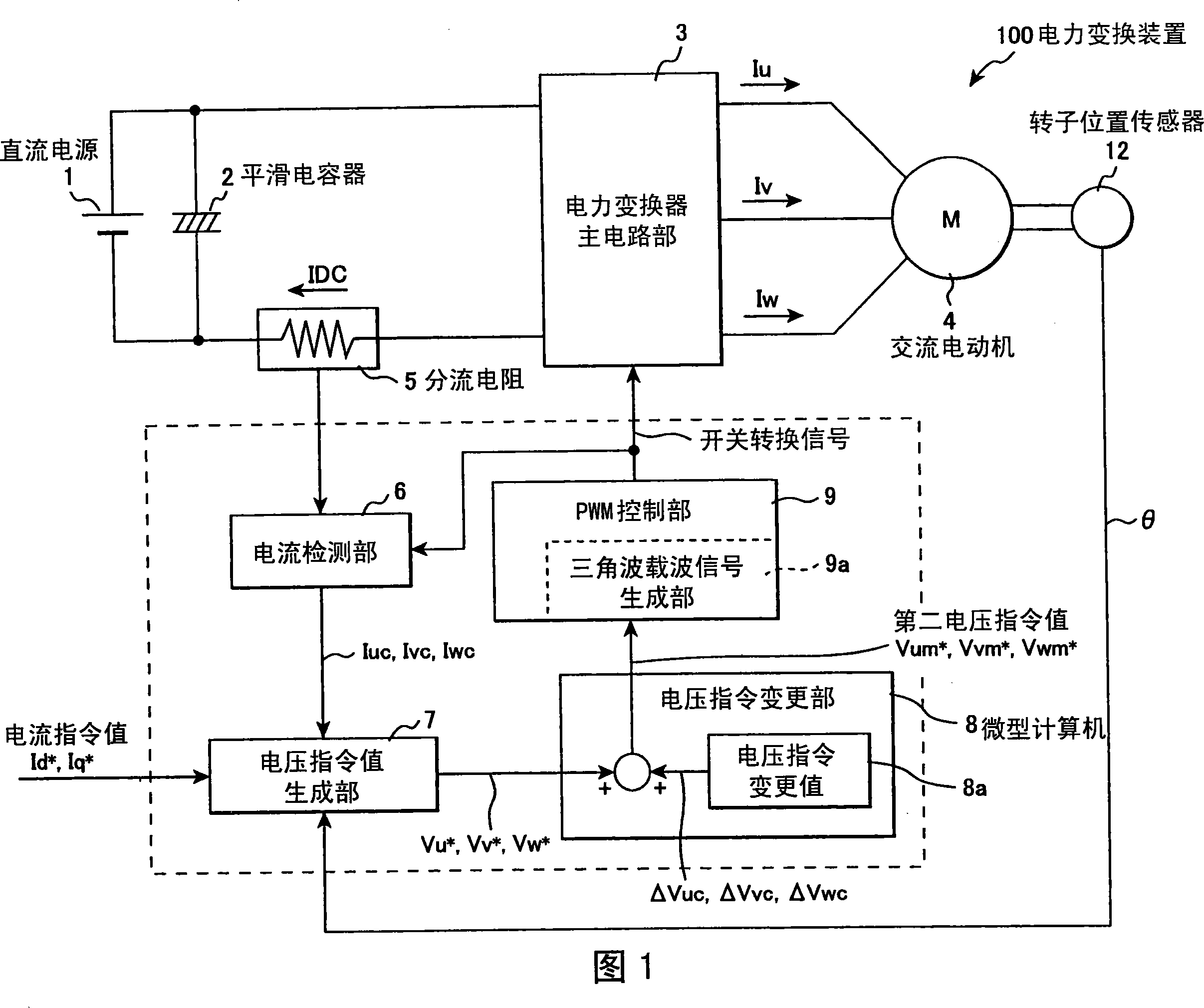

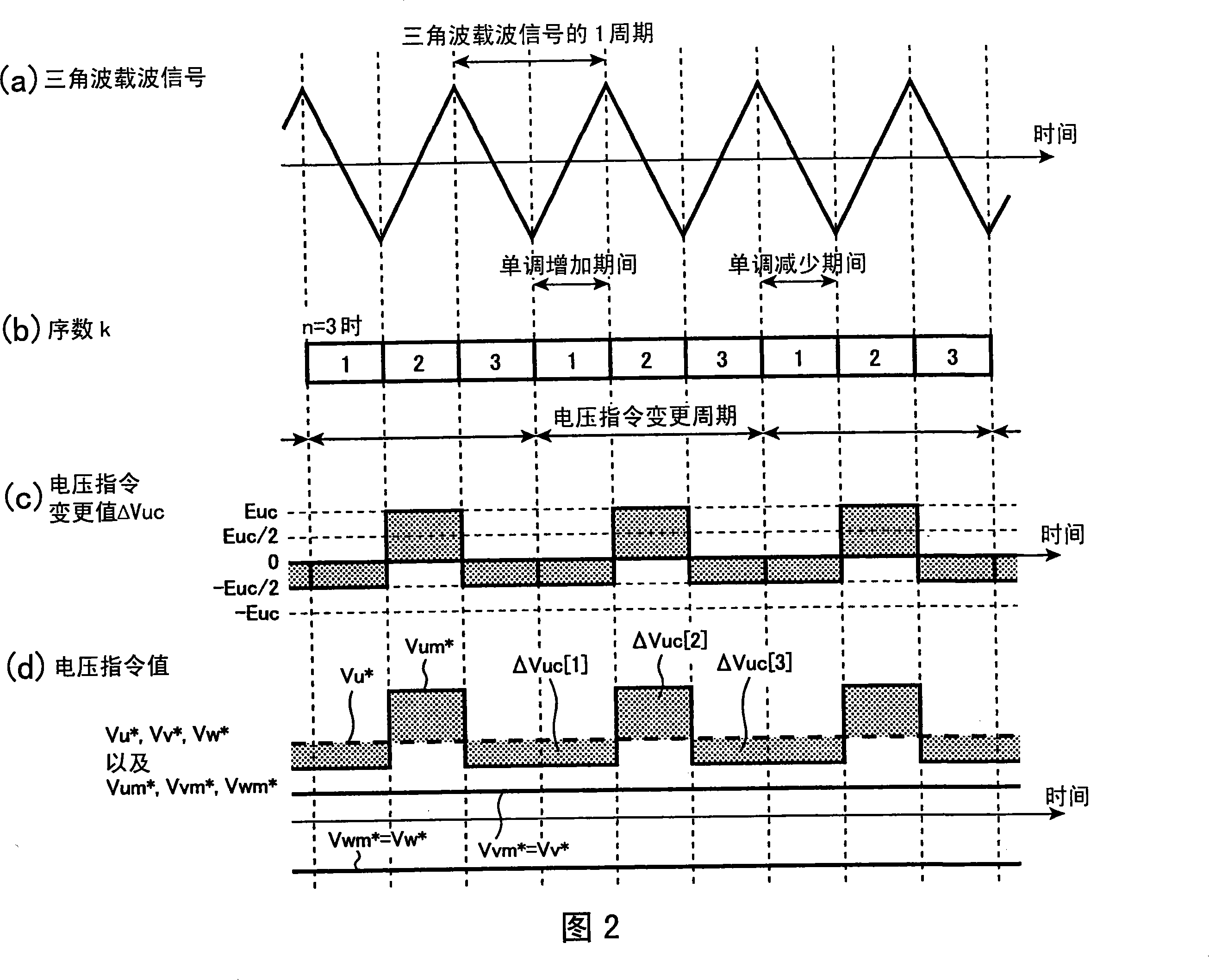

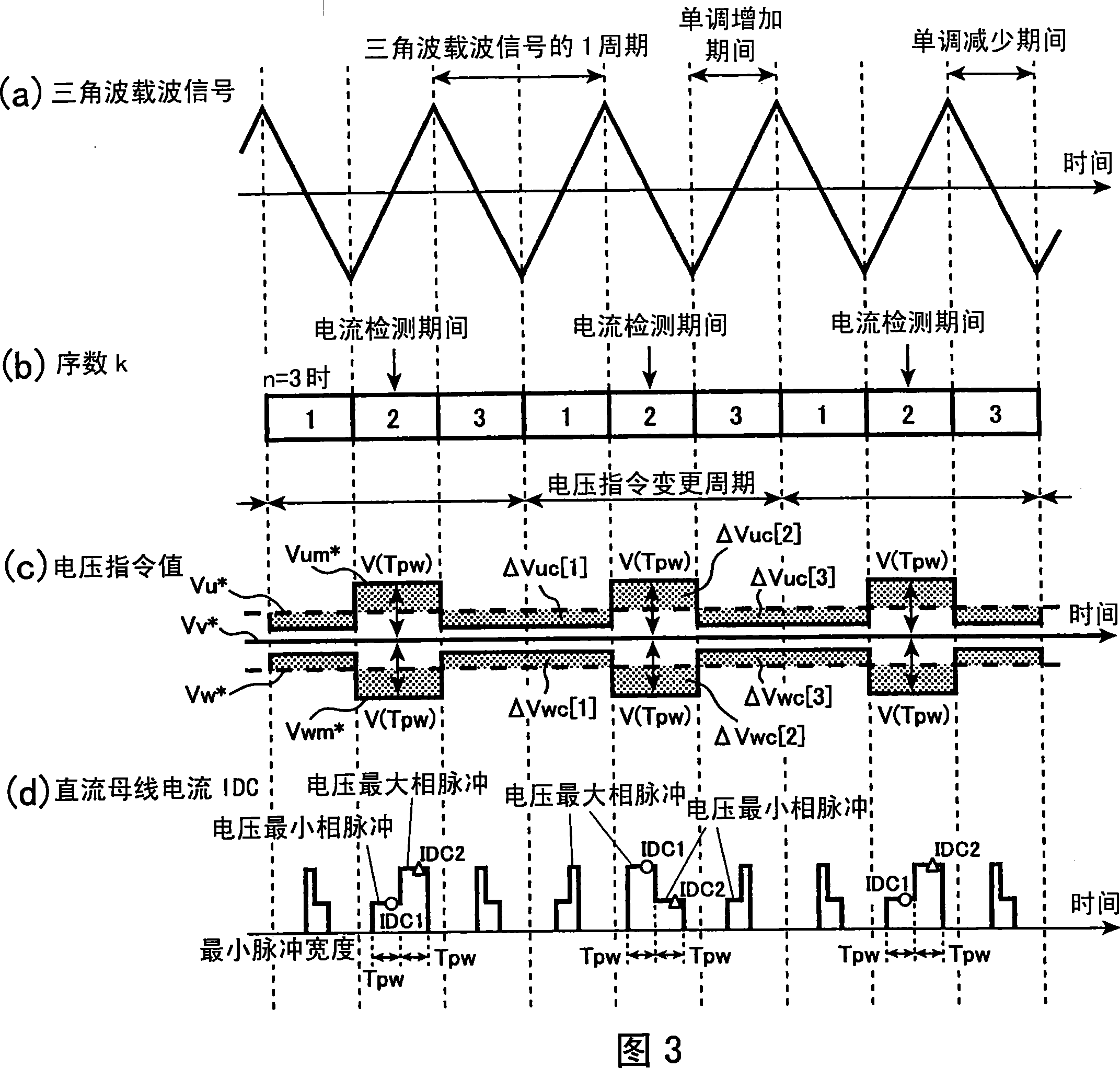

[0030] A first embodiment of the present invention will be described using the configuration diagram of FIG. 1 . The power conversion device 100 in FIG. 1 includes a DC power supply 1, a smoothing capacitor 2 connected in parallel, and a power converter main circuit section (power converter circuit section) that applies a voltage across the smoothing capacitor 2 to the input side through a shunt resistor 5. 3. An AC motor 4 connected to the AC output of the power converter 3, a rotor position sensor 12 installed on the AC motor 4 and outputting a rotor angle signal θ, and a microcomputer 8.

[0031] The microcomputer 8 has the following functions: the current detection unit 6 inputs the DC bus current IDC flowing in the shunt resistor 5, and reproduces the phase currents Iuc, Ivc, and Iwc; the voltage command value generation unit 7 inputs the reproduced phase currents Iuc, Ivc , Iwc and any externally applied current command value Id * ,Iq * , output the first voltage comma...

no. 2 approach

[0089] A second embodiment of the present invention will be described using the configuration diagram of FIG. 5 . In FIG. 5 , the power conversion device 110 is the configuration of the power conversion device 100 according to the first embodiment, with the rotor position sensor 12 deleted, and a rotor position estimation calculation unit 10 for estimating the rotor position of the AC motor 4 is added instead of the rotor position sensor. .

[0090] The rotor position estimation calculation unit 10 receives the reproduced currents Iuc, Ivc, and Iwc obtained by reproducing the motor currents Iu, Iv, and Iw as input, performs estimation calculation of the rotor position, and outputs a phase signal θc of the estimated rotor position. The rotor position estimation calculation uses the first voltage command value Vu * 、Vv * 、Vw * , internal resistance and inductance of the AC motor 4 and other motor constant values for calculation. The voltage command generation unit 7 acquir...

no. 3 approach

[0092] A third embodiment of the present invention will be described using the configuration diagram of FIG. 6 . In FIG. 6 , a power conversion device 120 constitutes a speed control system by adding a speed control unit 11 to the configuration of the power conversion device 110 of the second embodiment. The speed control unit 11 uses the output of the rotor position estimation operation unit 10, that is, the speed estimated value ωc and the arbitrarily applied speed command value ω1 * As input, output the d-axis current command value Id * and the q-axis current command value Iq * . The estimated speed value ωc is a differential value of the phase signal θc of the estimated rotor position calculated by the rotor position estimated calculation unit 10 . The speed control unit 11 compares the speed command value ω1 * and the estimated speed value ωc, thereby performing speed control.

[0093] In addition, in the case of configuring a speed control system, the rotor angle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com