Gantry type ultra-precise fly miller

An ultra-precision, gantry-type technology, applied in the field of milling machines, can solve problems such as failure to provide, and achieve the effects of easy operation, symmetrical structure, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

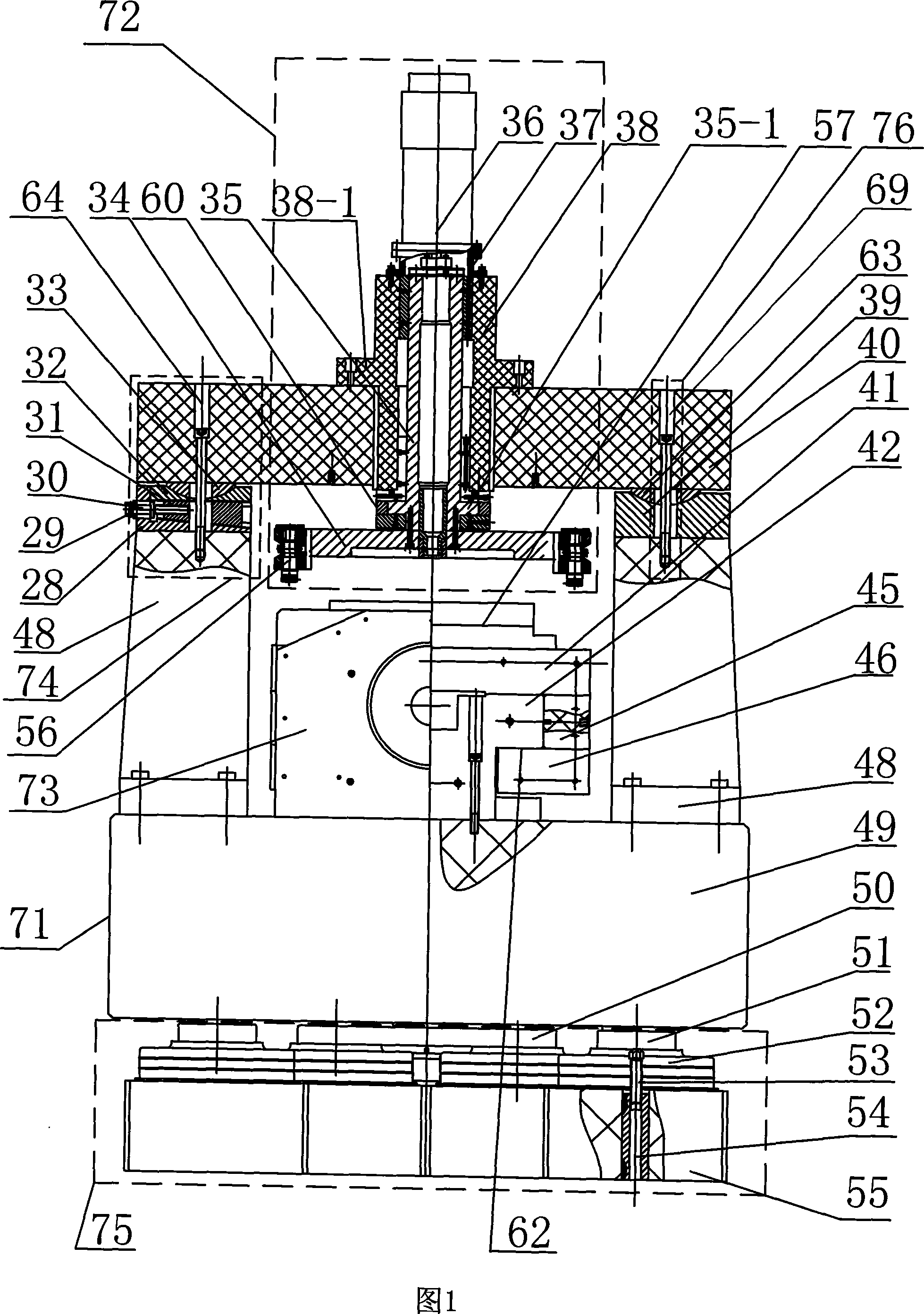

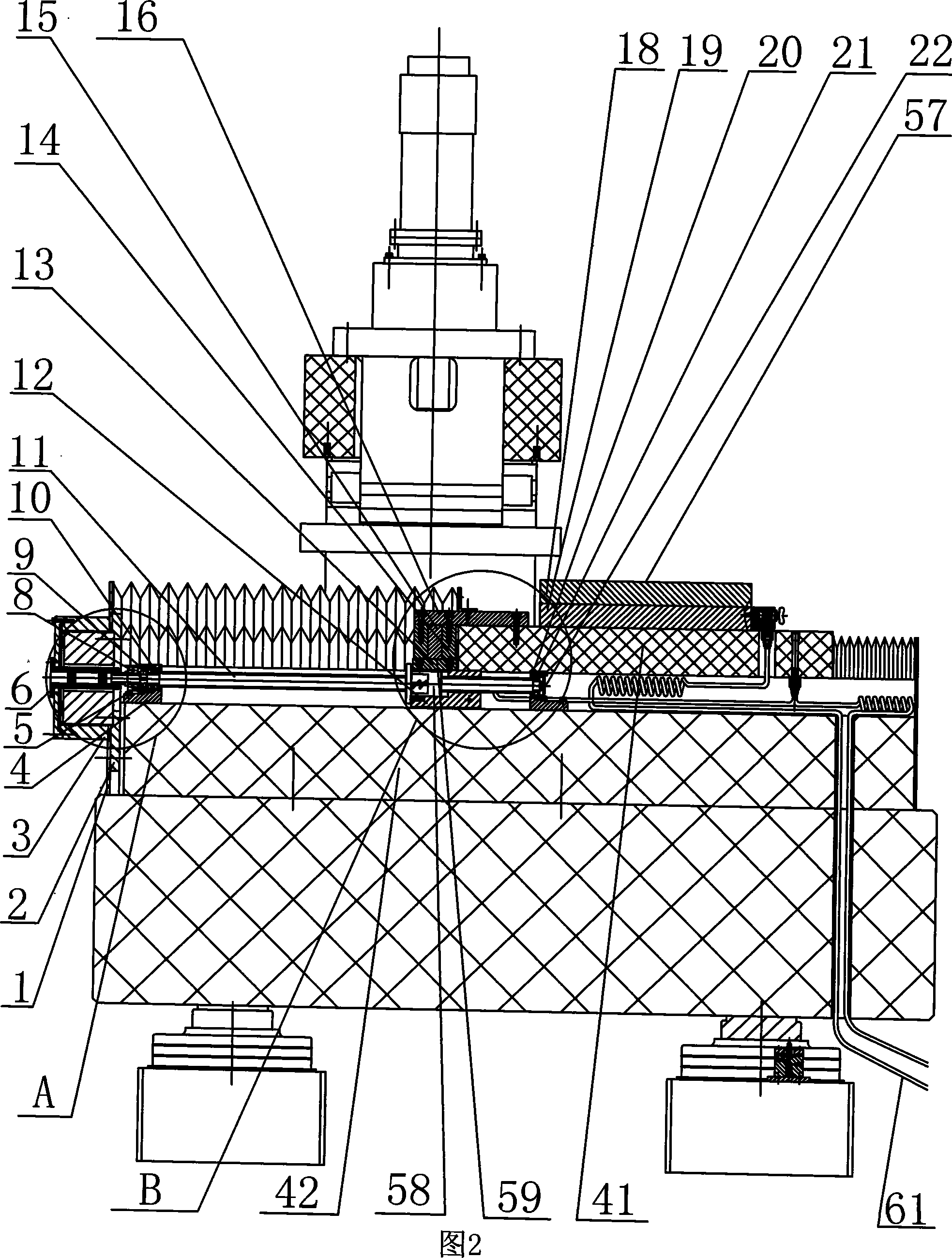

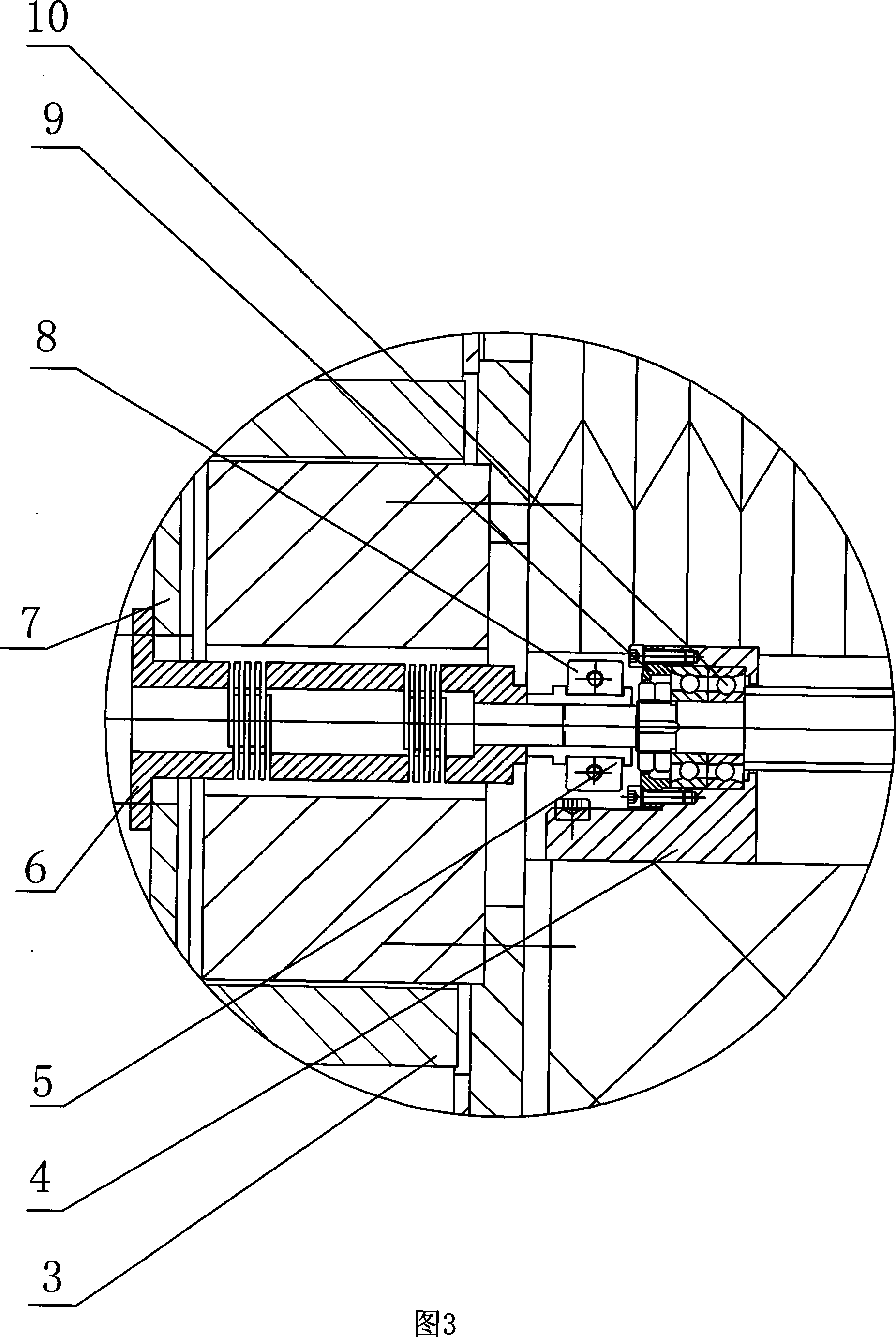

[0007] Specific embodiment one: as shown in Figures 1 to 4, the gantry-type ultra-precision fly-cutting milling machine of this embodiment is composed of a gantry-type bed 71, a spindle system 72, a linear guide rail system 73, and a high-pressure gas pipeline device 61; The gantry bed 71 is composed of a crossbeam 40, two columns 48, and a base 49. The spindle system 72 is composed of a spindle motor 36, a gas static pressure spindle 35, a spindle sleeve 38, a gas static pressure bearing 60, and a flying cutter head. 34. The tool assembly 56 is composed of the linear guide rail system 73 consisting of a guide rail 42, an upper slide 41, two lower slides 46, two intermediate slides 45, a vacuum sucker 57, a motor 3, a flexible coupling 6, Lead screw 11, screw nut 58, gas static pressure coupling 59, screw seat 4, screw back seat 20, screw bearing 10, rear bearing 21, screw nut air bearing seat 12, and locking device 8 are composed; The two columns 48 are located on the left an...

specific Embodiment approach 2

[0011] Embodiment 2: As shown in FIGS. 1-4 , the vacuum chuck 57 in this embodiment is composed of an upper suction cup 18 and a lower suction cup 19 . Such a design facilitates the processing of air holes in the vacuum suction cup. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: As shown in Figures 1 to 4, the gas static pressure coupling 59 in this embodiment is composed of an air-floating push plate seat 13, an air-floating push plate 15, two air-floating thrust plates 14, an air-floating push plate Thrust plate bearing 16 is formed, and described air-floating thrust plate seat 13 is fixedly connected with the lower end of air-floating pushing plate 15, and two air-floating thrusting plates 14 are positioned at the both side end surfaces of air-floating pushing plate 15, two air-floating pushing plate 15 The upper end of the floating thrust plate 14 is fixedly connected with the air-floating thrust plate support 16 . Such a design facilitates processing and improves movement precision. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com