Zirconium alloy composition having excellent corrosion resistance for nuclear applications and method of preparing the same

A corrosion-resistant, zirconium alloy technology, used in nuclear engineering, reactors, nuclear power generation, etc., can solve problems such as increasing the serious corrosion of nuclear fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Typical methods known in the art can be used to prepare the zirconium alloy composition of the present invention, and its preparation method preferably includes the first step of mixing and melting alloying elements to prepare an ingot, which will be prepared in the first step The ingot is heat-treated in the β-zone and the second step of cooling it, the ingot heat-treated and cooled in the second step is subjected to the third step of hot rolling and the ingot treated in the third step is subjected to cold rolling And heat treatment, thereby preparing the fourth step of zirconium alloy. After the cold rolling in the fourth step, a final heat treatment may also be included.

[0042] Hereinafter, the preparation method of the present invention will be described step by step in detail.

[0043] The first step is a process of mixing alloying elements at a predetermined ratio and melting them, thereby preparing an ingot.

[0044] The ingot is preferably prepared using a v...

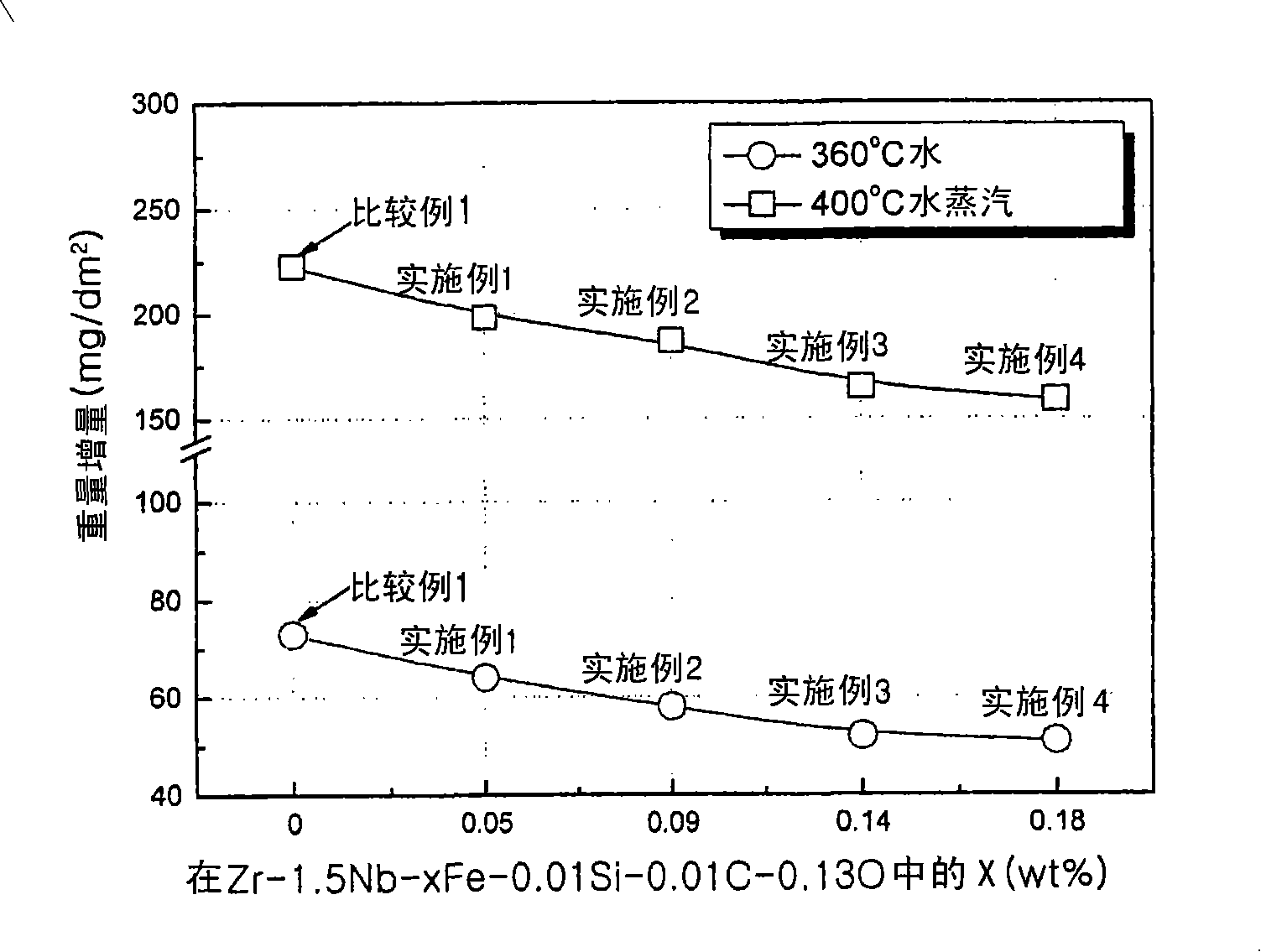

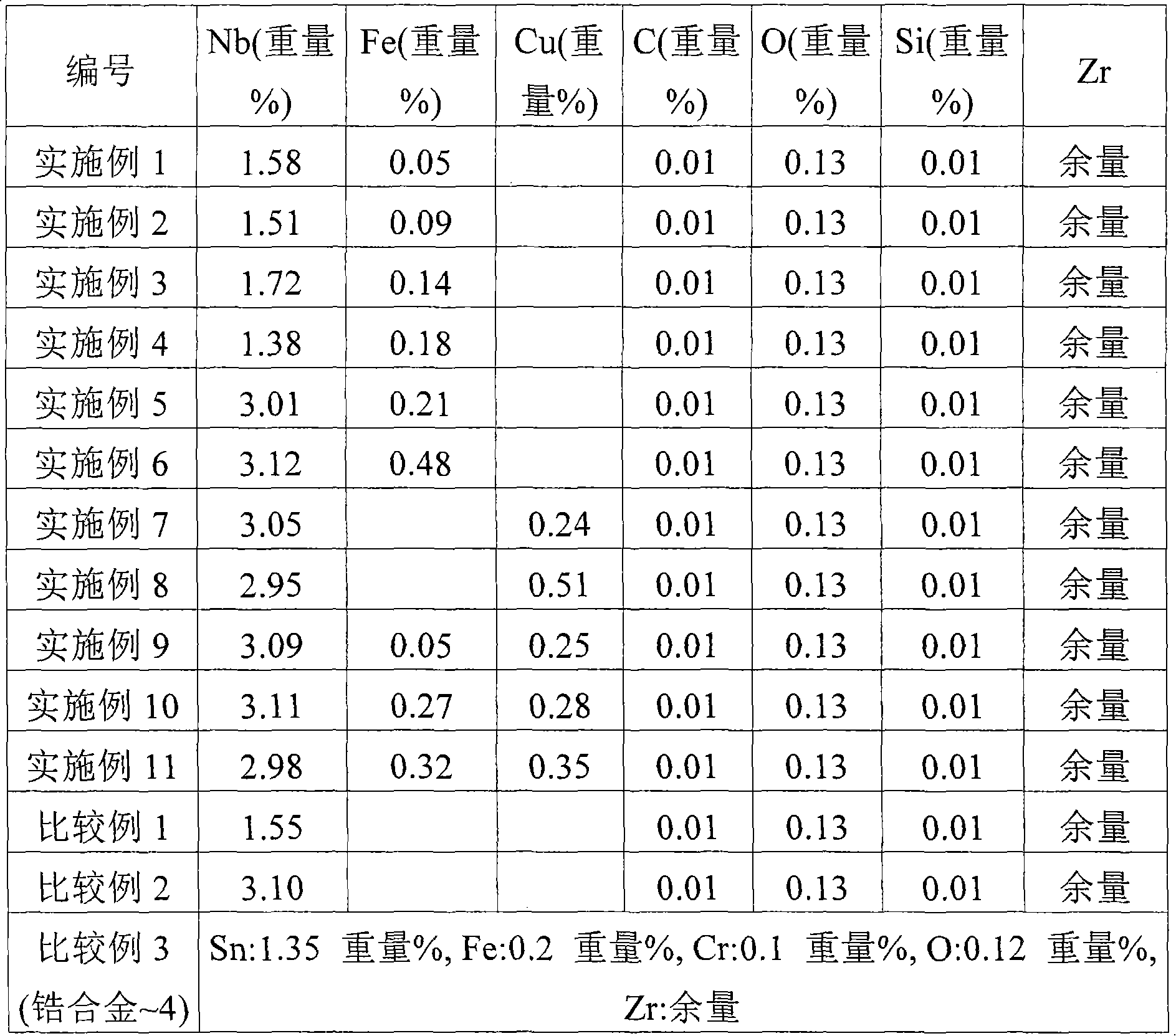

Embodiment 1

[0055] The preparation of zirconium alloy

[0056] (1) Preparation of ingot

[0057] A zirconium alloy composition comprising 1.58 wt. % niobium, 0.05 wt. % iron, 0.01 wt. % silicon, 0.01 wt. % carbon and 0.13 wt. % oxygen with the balance zirconium was subjected to VAR to prepare a button-shaped ingots. Also, reactor-grade zirconium sponge described in ASTM B349 was used as zirconium, and the alloying elements had a high purity equal to or higher than 99.99%. In addition, silicon, carbon, and oxygen are first melted together with zirconium sponge to prepare a master alloy, and then, when the ingot is melted, the master alloy is added in a required amount. To prevent segregation of inclusions or uneven distribution of alloy components, the melting treatment was repeated four times. In addition, in order to prevent oxidation during melt processing, the vacuum state in the chamber is kept at 1×10 -5 Torr, inject high-purity argon gas with 99.99%, and apply a current of 500A...

Embodiment 2

[0067] This example was carried out in the same manner as in Example 1, except that a compound containing 1.51% by weight of niobium, 0.09% by weight of iron, 0.01% by weight of silicon, 0.01% by weight of carbon, and 0.13% by weight of oxygen was used, And a zirconium alloy composition with the balance being zirconium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com