CMOS image sensor and its production method

An image sensor and manufacturing method technology, applied in the field of image sensors, can solve problems such as unclear imaging, decreased photosensitivity, and reduced light energy of photodiodes, and achieve the effects of increased light energy, improved photosensitivity, and clear imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

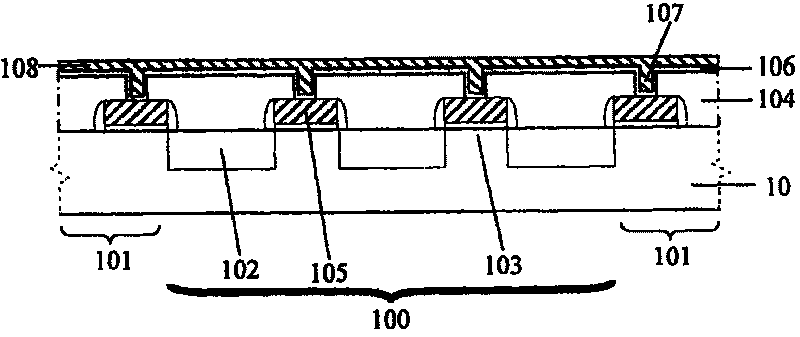

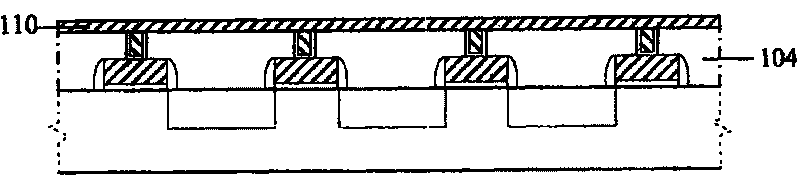

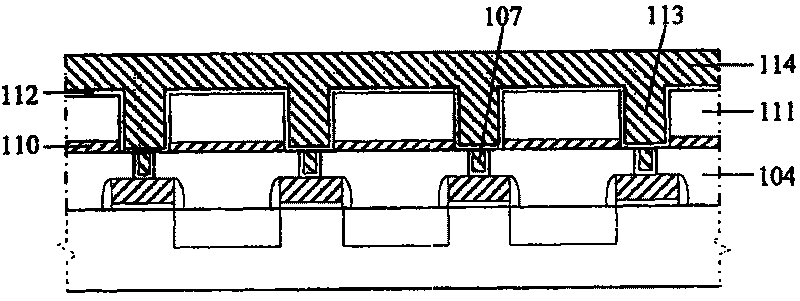

[0047] The CMOS image sensor receives light through the photodiode and converts the light signal into an electrical signal. In order to enhance the light energy received by the photodiode and improve the photosensitivity, the thin film structure of the light channel can be optimized to reduce the loss of light during propagation. . The present invention removes the multi-layer insulating layer and the etching stop layer in the image sensing area without metal connection, fills the light-transmitting resin material or directly etches the multi-layer insulating layer and the etching stop layer into a microlens, so that the light is reflected The reduced amount of absorption and absorption increases the light energy received by the photodiode and increases the photosensitivity, thereby realizing that the light environment used by the CMOS image sensor is not limited, and the imaging is clear under darker environmental conditions. In order to make the above objects, features and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com