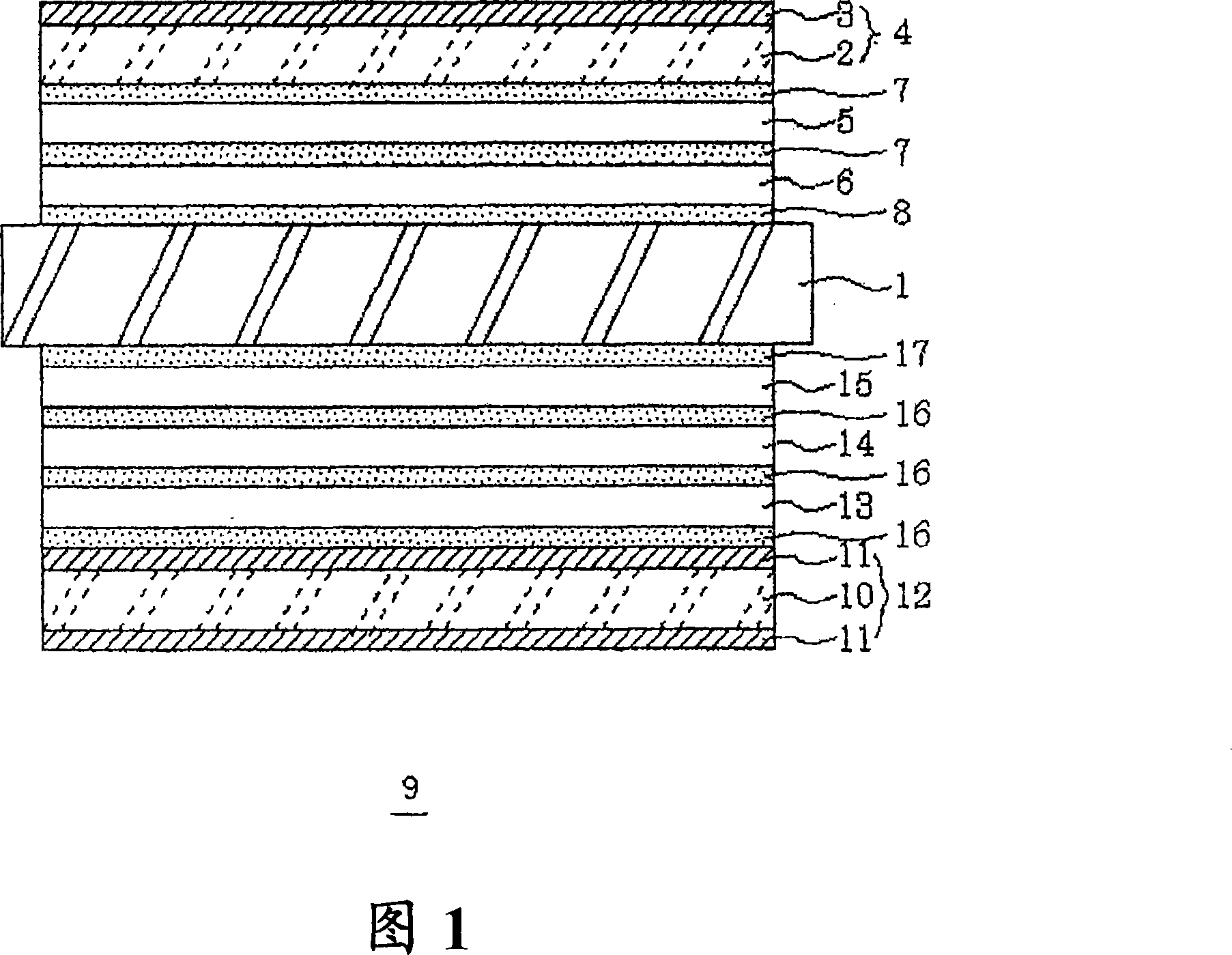

Light deflection panel

A technology of polarizing plates and polarizers, applied in the field of polarizing plates, can solve problems such as insufficient adhesion of polarizers, achieve optical performance or shape stability, prevent optical performance from deteriorating, and improve heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

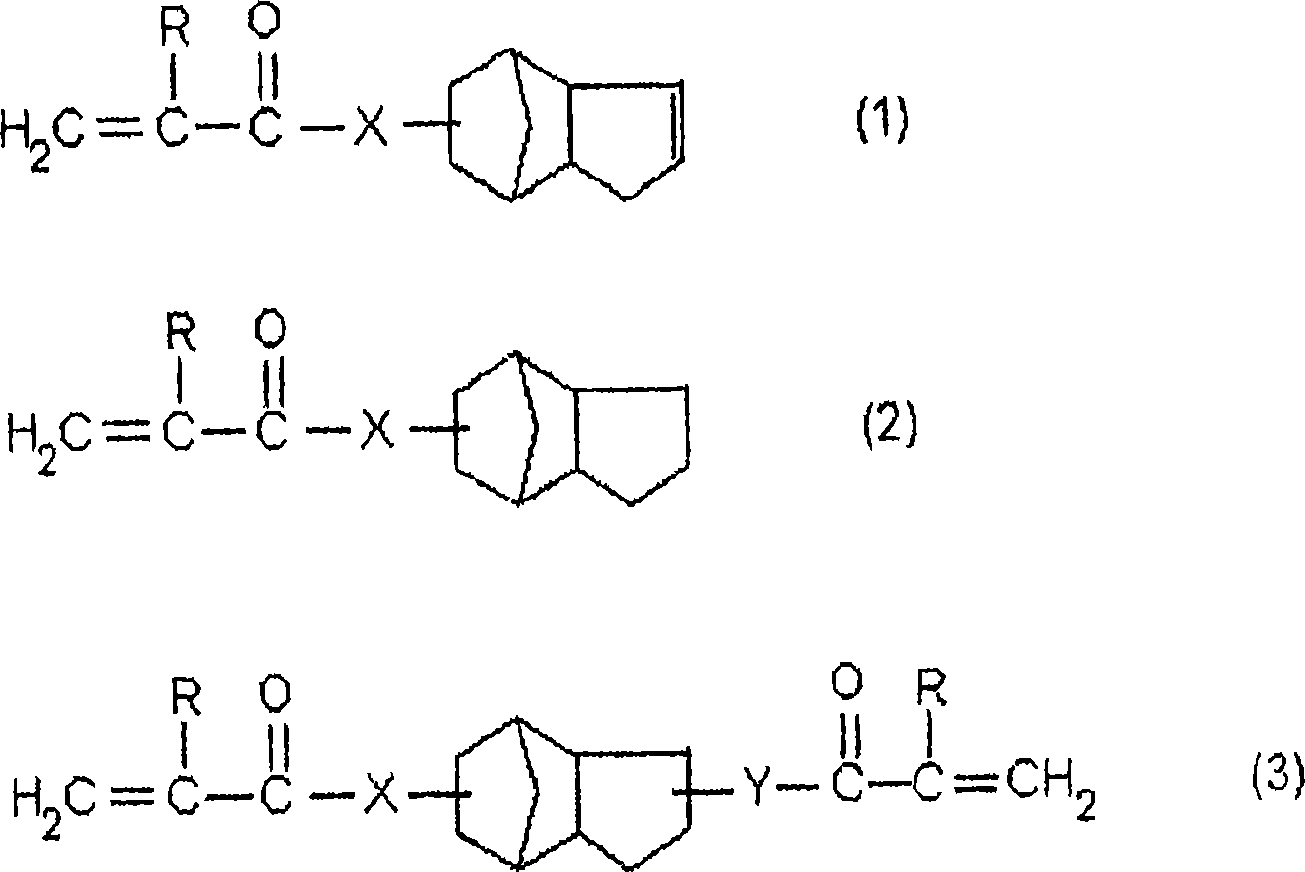

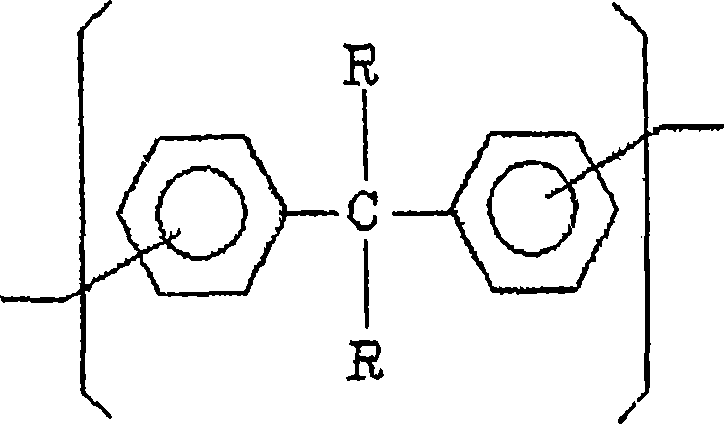

Method used

Image

Examples

Embodiment 1-16 and comparative example 1、2

[0110] (1) Production of polarizers

[0111] The degree of saponification is 99.5% mol polyvinyl alcohol film (75 μm thick) soaked in pure water, fully swollen, then at 35 ℃, in iodine staining solution (iodine / potassium iodide / boric acid / pure water=0.2g / 30g / 30g / 1L) for 4 minutes for dyeing. The dyed polyvinyl alcohol film was uniaxially stretched to 5 times or more in a stretching solution (potassium iodide / boric acid / pure water=30 g / 30 g / 1 L). Soak the stretched polyvinyl alcohol film in a solution for fixation (potassium iodide / boric acid / pure water=40g / 40g / 1L) at 40°C for 3 minutes to fix iodine in the film of polyvinyl alcohol, and then remove it from the solution for fixation. Take it out, and dry it in a drying oven (65° C., 5 minutes) to prepare a polarizer.

[0112] (2) Formation of protective film

[0113] As shown in Table 1, using 3% boric acid water, at 60°C, stir the silane coupling agent with the corresponding amount of water for 6 hours to hydrolyze, mix an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com